V Series Level Display Calibration

1) In order to calibrate the liquid level display there must be at least 5 inches of liquid nitrogen

in the storage vessel. With this in mind, bring the liquid level in the storage vessel up to a

level where it is possible to note the actual measurement of the liquid level.

2) Unplug the storage unit from its power source.

3) Access the printed circuit board inside the controller unit. On the Series 1500 and 3000, this

is done by removing the two screws at the bottom of the controller back plate and sliding

the controller out. On the 5000, the back access door to the controller comes off by removing

the screws which hold it in place.

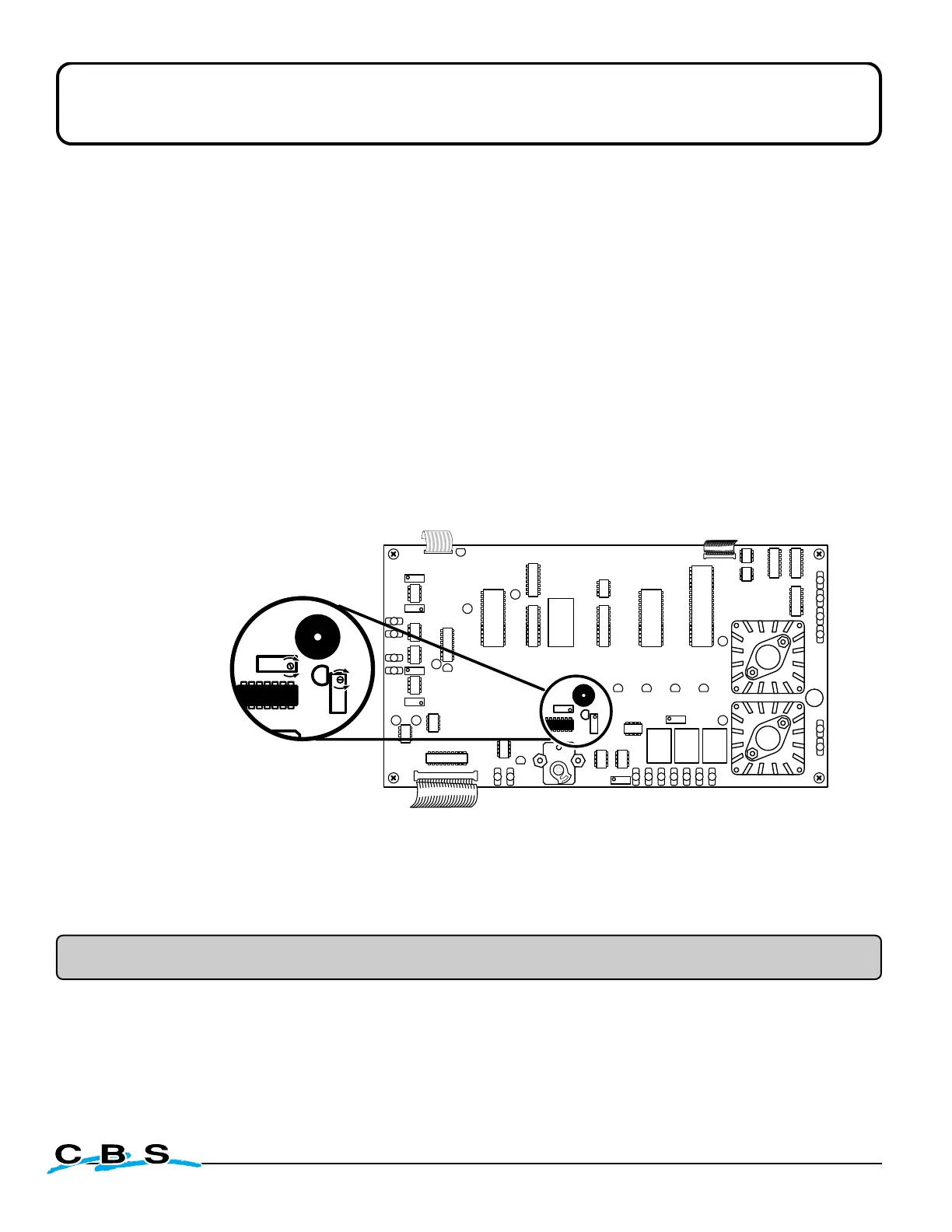

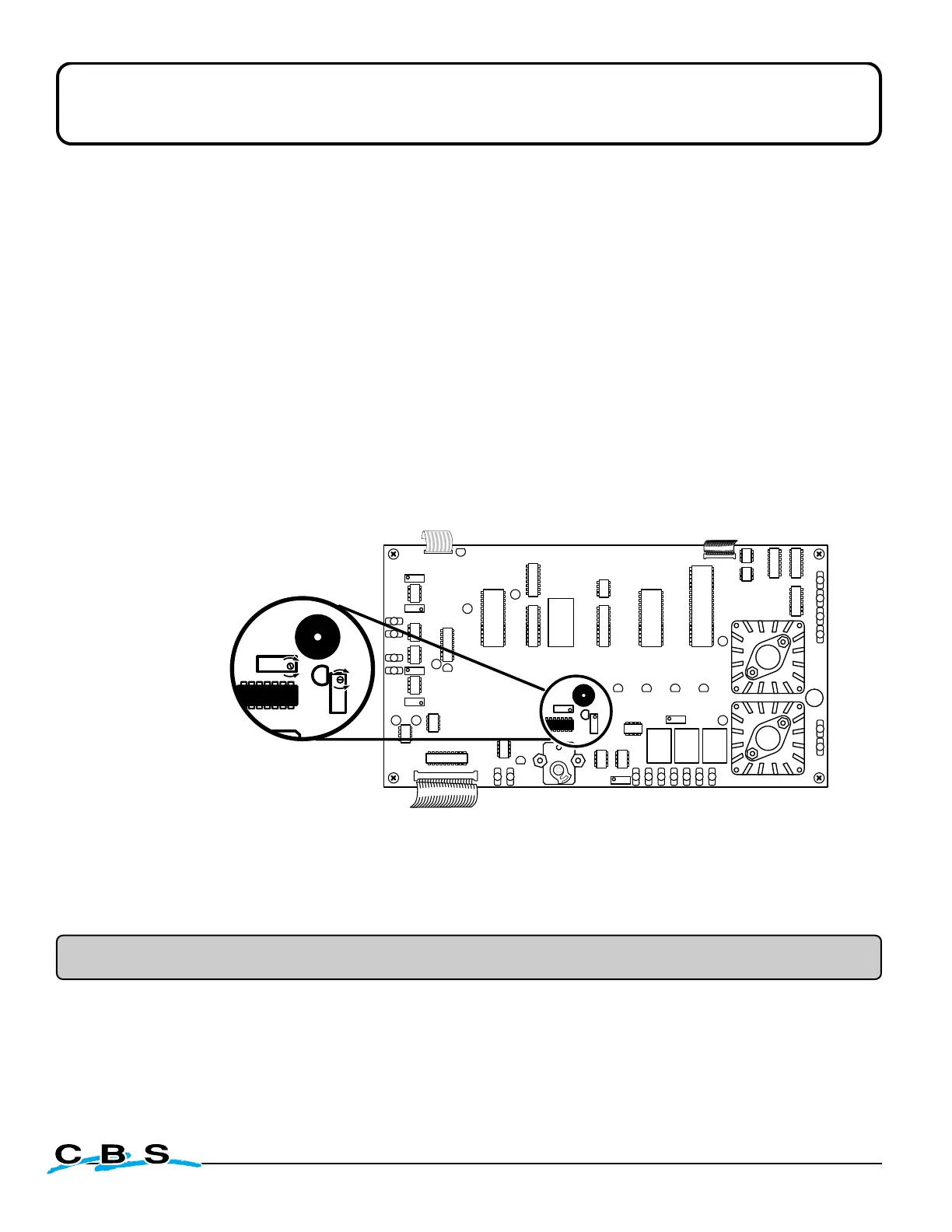

4) Once the circuit board is in view, locate the P6 & P7 Level Display Calibration Trimmers. See

diagram below for help identifying the proper location.

5) Reconnect power to the unit.

6) If display reading is below the actual liquid level, turn the P6 adjustment very slowly

counterclockwise until display reading matches the actual liquid level.

7) If display reading is above the actual liquid level, turn the P6 adjustment very slowly clockwise

until the display reads the actual liquid level.

8) Now disconnect the Level Sensor, turn the P7 adjustment counterclockwise until the display

reads less than zero, then turn the P7 clockwise to zero. Reconnect the Level Sensor.

9) Wait 15 minutes and re-check the level display against the actual liquid level to be sure

the setting has remained accurate.

10) Once again unplug the controller from its power source.

11) Replace controller into the 1500 or 3000, or back cover onto the 5000, and secure the screws.

12) Reconnect all connections, and power to the unit, and proceed to normal operation.

Loading...

Loading...