3

-

WSC Wire start control. This arc striking control device pre-

vents wire from sticking to the workpiece or torch nozzle

and ensures precise and smooth arc striking, particularly

when welding aluminium.

-

Welding parameters that are controlled digitally by a micro-

processor, are monitored and modified in just a few sec-

onds, maintaining a consistently precise and stable arc as

the welding conditions continue to vary due to the move-

ment of the torch and the irregularities of the parts to be

welded.

-

Exclusive SWS “Smart Welding Stop” system at the end of

TIG welding. Lifting up the torch without switching off the

arc will introduce a slope down and it will switch off auto-

matically.

-

“Energy Saving” function to operate the power source cool-

ing fan and the torch water cooling only when necessary.

- Auto-diagnostic feature for trouble shooting.

- Password-controlled total or partial equipment access.

• High electrical performance resulting in a reduction in ener-

gy consumption.

• Remote parameter adjustment directly from HT4 feeder.

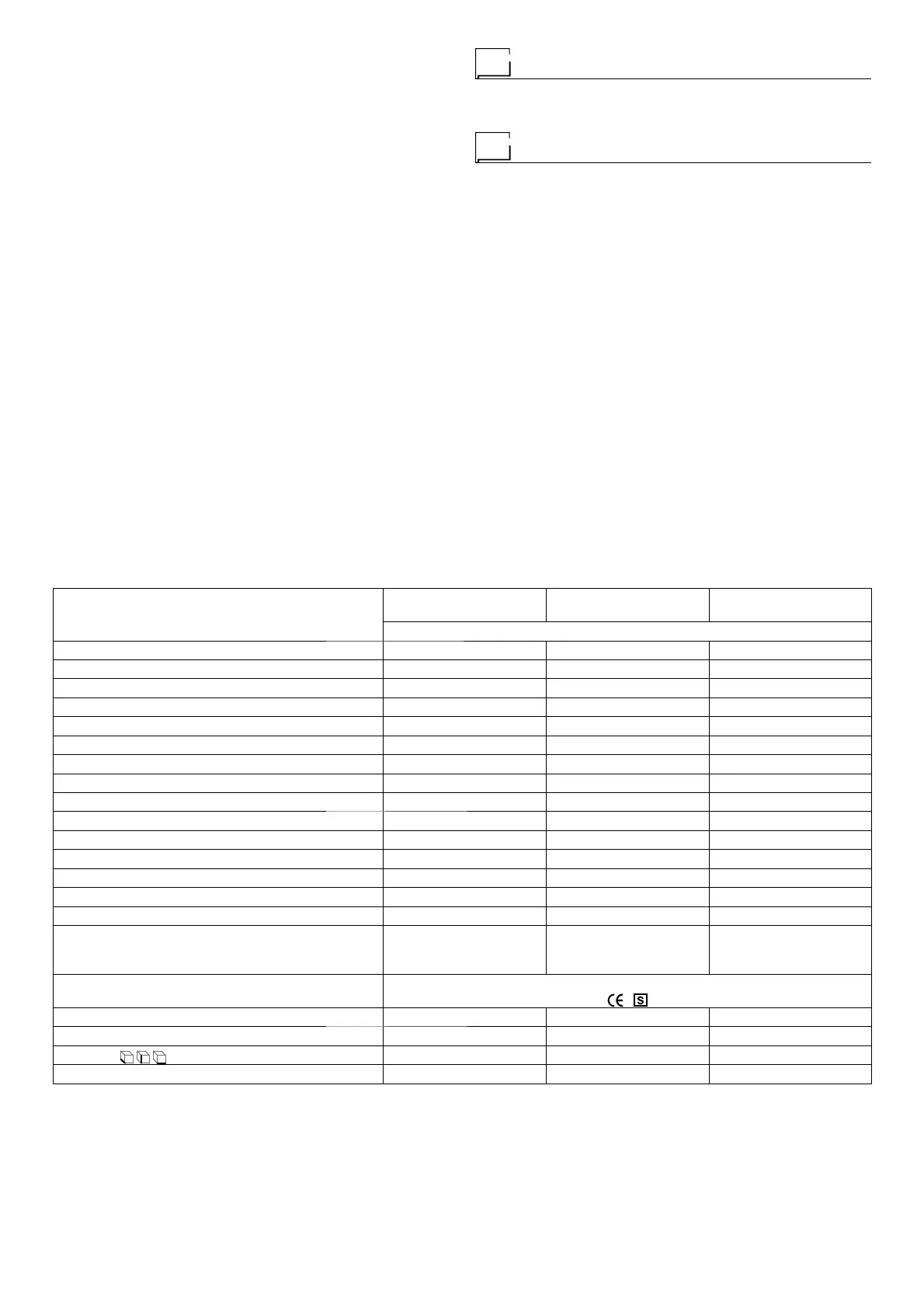

Technical data

The general technical data of the system are summarized in

table 1.

Usage limits (IEC 60974-1)

The use of a welder is typically discontinuous, in that it is made

up of effective work periods (welding) and rest periods (for the

positioning of parts, the replacement of wire and underflush-

ing operations etc. This welder is dimensioned to supply a I

2

max nominal current in complete safety for a period of work of

40/50% of the total usage time. The regulations in force estab-

lish the total usage time to be 10 minutes. The work cycle is

considered to be 40/50% of this period of time. Exceeding the

work cycle allowed could cause a trip switch to trip (for further

information see the DH control panel manual), which protects

the components inside the welding machine against dangerous

overheating. After several minutes the overheat cut-off rearms

automatically and the welder is ready for use again.

Table 1

Model

DIGITECH vision PULSE

3300

DIGITECH vision PULSE

4000

DIGITECH vision PULSE

5000

MIG-MAG welding

Three-phase input 50/60 Hz V 400 ± 20% 400 ± 20% 400 ± 20%

Mains supply: Z

max

Ω 0,037 0,028 0,017

Input power @ I

2

Max kVA 18,8 25,5 32

Delayed fuse (I

2

@ 60%) A253040

Power factor / cosφ 0,64 / 0,99 0,66 / 0,99 0,66 / 0,99

Efficiency degree η 0,83 0,86 0,89

Open circuit voltage V637070

Current range A 10 ÷ 330 10 ÷ 400 10÷500

Duty cycle @ 100% (40°C) A 280 330 380

Duty cycle @ 60% (40°C) A 300 370 460

Duty cycle @ X% (40°C) A 330 (40%) 400 (50%) 500 (50%)

Wires diameter (*) mm 0,6 ÷ 1,2 (*) 0,6 ÷ 1,6 (*) 0,6 ÷ 1,6 (*)

N° rollers (*) 4 (*) 4 (*) 4 (*)

Power output of feeder motor (*) W 100 (*) 100 (*) 100 (*)

Rated wire feeding speed (*) m/min 0,5 ÷ 25 (*) 0,5 ÷ 25 (*) 0,5 ÷ 25 (*)

Spool (*)

Diameter

Weight

mm

kg

Ø300 (*)

15 (*)

Ø300 (*)

15 (*)

Ø300 (*)

15 (*)

Standards

IEC 60974-1 - IEC 60974-5 (*) - IEC 60974-10

Protection class IP 23 S IP 23 S IP 23 S

Insulation class HHH

Dimensions mm 660 - 515 - 290 660 - 515 - 290 660 - 515 - 290

Weight kg 35 40 44

(*) On the HT4 feeder, fitted separately.

WARNING: This equipment complies with EN//IEC 61000-3-12 provided that the maximum permissible system impedance Z

max

is less than or

equal to 0,037 Ω DIGITECH vision PULSE 3300 - 0,028 Ω DIGITECH vision PULSE 4000 - 0,017 Ω DIGITECH vision PULSE 5000 at the in-

terface point between the user’s supply and the public system. It is the responsibility of the installer or user of the equipment to ensure, by con-

sultation with the distribution network operator if necessary, that the equipment is connected only to a supply with maximum permissible system

impedance Z

max

less than or equal to 0,037 Ω DIGITECH vision PULSE 3300 - 0,028 Ω DIGITECH vision PULSE 4000 - 0,017 Ω DIGITECH

vision PULSE 5000.

This system, tested according to EN/IEC 61000-3-3, meets the requirements of EN/IEC 61000-3-11.

Loading...

Loading...