29

• CEDIMA® • Technical Documentation • All rights reserved according to ISO 16016 • Changes serving technical progress reserved •

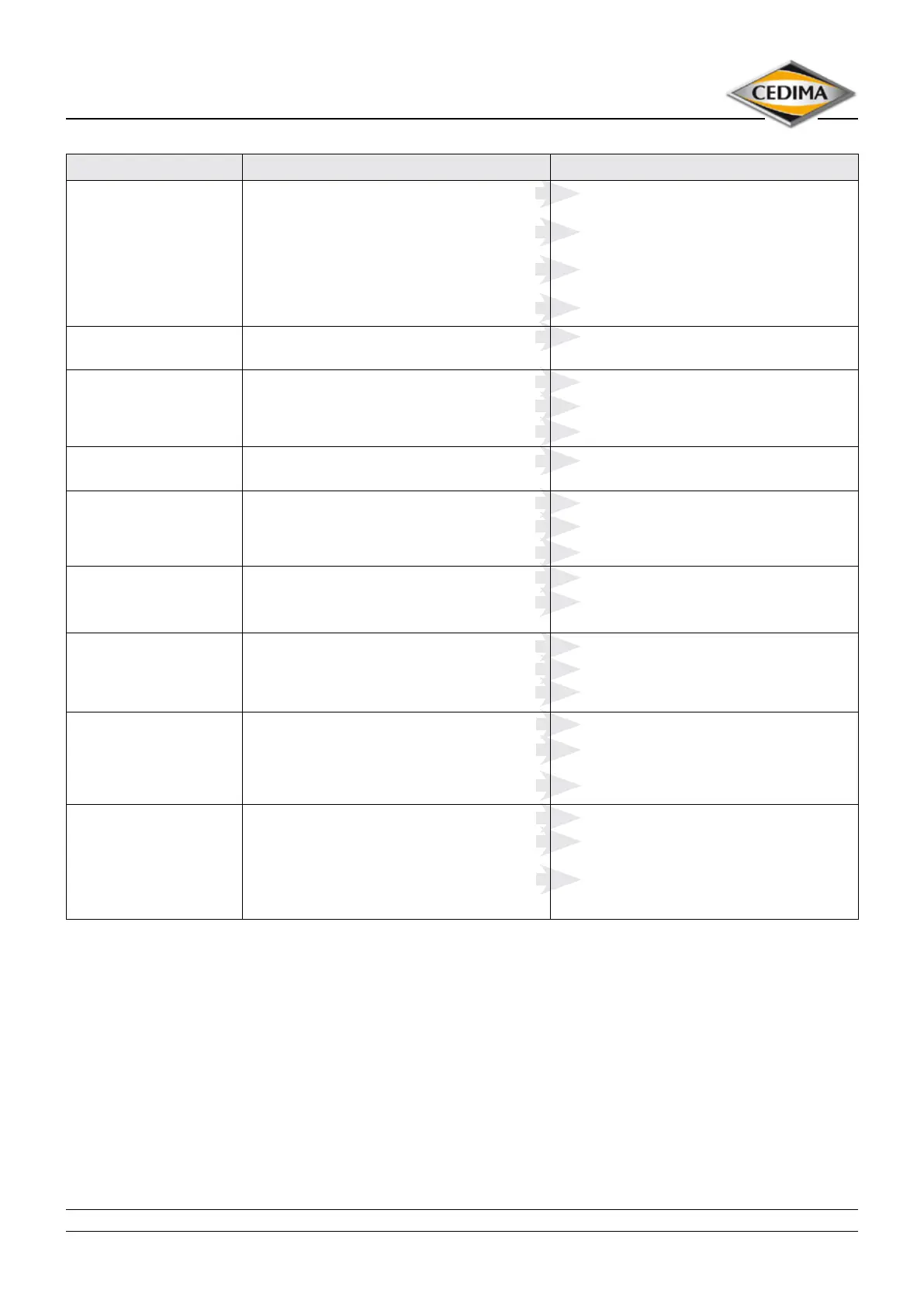

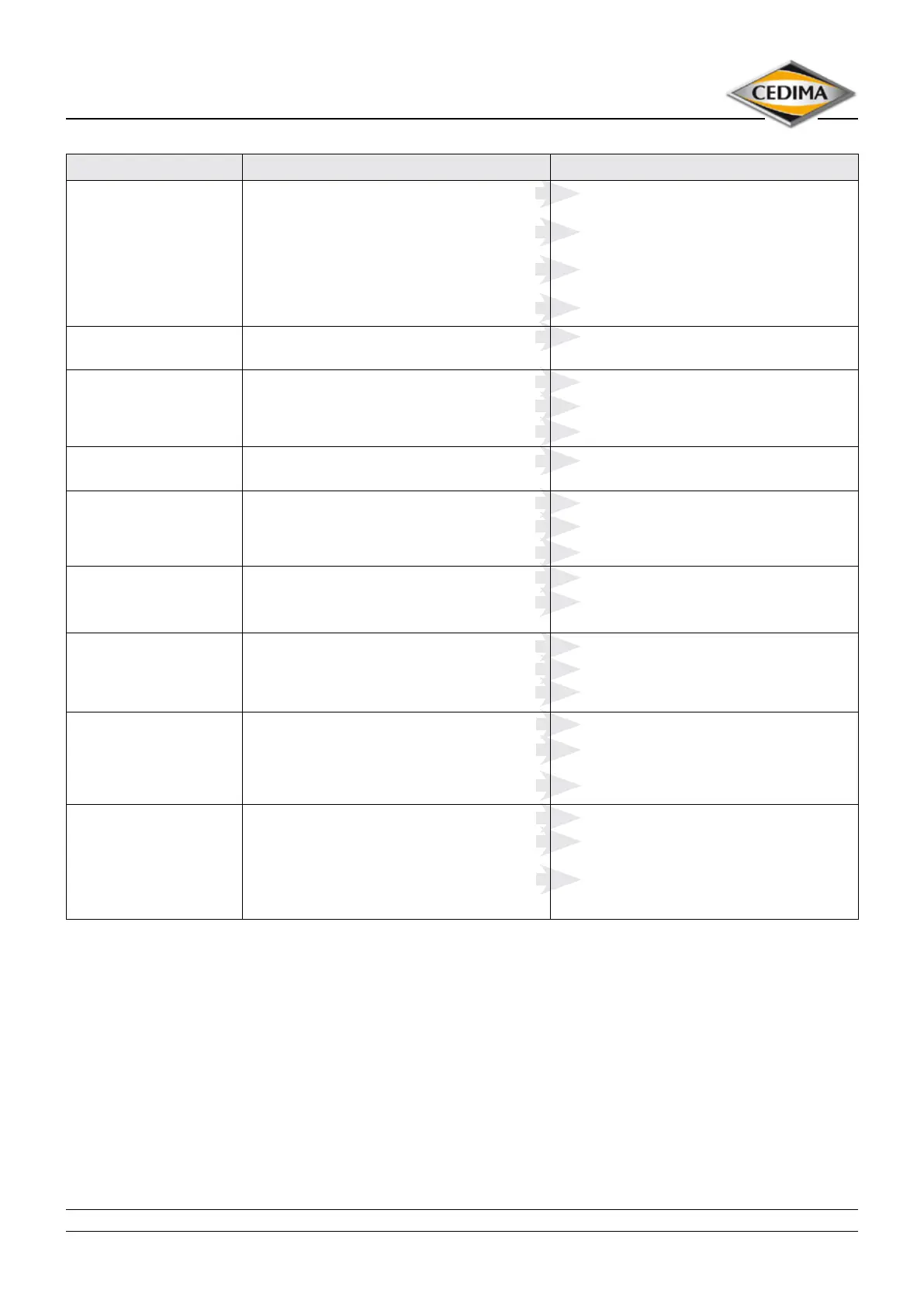

Trouble shooting, what if . . . ?

Joint cutter CF•22 E

Problem Possible cause

Remedy

The saw blade does not cut The saw blade is mounted backwards against the

direction of rotation

The saw blade is not matched to the material to be cut

(possibly it is too hard)

The saw blade is not matched to the machine power

output

Diamond segments are blunt

Mount the saw blade according to the direction of

rotation of the cutting shaft

Use the correct type of saw blade

Use the correct type of saw blade

Resharpen the saw blade

Cracks in the saw blade steel

core

The saw blade is too “hard” Use a“softer” saw blade

Cutting line is not optimal Poor saw blade tension (steel core)

The saw blade is overloaded

Diamond segments are blunt

Return the saw blade to the manufacturer

Reduce the feed rate (cutting depth)

Resharpen the saw blade

The saw blade has rotated on

the cutting shaft

Driving pin defective, missing Replace, insert the driving pin

The saw blade remains under

load

The V-belt is slipping

The V-belt is defective (torn)

Driving pin defective, missing

Tension the V-belt

Change the V-belt

Replace, insert the driving pin

The saw blade has become

coloured

The saw blade is overheated

The saw blade is subjected to excessive lateral friction

Optimise the cooling water feed

Reduce the feed rate

Do not tilt the saw blade in the cut

Chang points on the saw

blade

The feed direction is not parallel to the saw blade

The saw blade is overloaded

Poor saw blade tension

Do not tilt the saw blade in the cut

Reduce the advance speed

Return the saw blade to the manufacturer

Diamond segments show signs

of eccentric wear

The cutting shaft has shrunk

The mount for the saw blade is worn out (cutting shaft,

saw blade bore)

Excessive bearing play on the cutting shaft

Renew the cutting shaft

Turn out the saw blade mounting hole and adapt to the

correct diameter using aring

Replace the bearing or the cutting shaft

Areduced or no cooling water

ow

The water supply is not optimal

The water hoses are blocked, defective, come o, kinked

The shut-o valve is blocked, defective, not opened

Adapt the pressurised water supply

Clean the water hoses, check them, connect them,

replace them if necessary

Clean, check, open the shut-o valve; replace it if

necessary

The problems and their possible causes are mainly due to natural wear and to incorrect use of the joint cutter or the

diamond saw blades!

Therefore you should read this operating manual thoroughly!

Loading...

Loading...