25

• CEDIMA® • Technical Documentation • All rights reserved according to ISO 16016 • Changes serving technical progress reserved •

Maintenance and care

Joint cutter CF•22 E

5.7 Maintenance work

ATTENTION!

Observe the safety instructions of this operating manual

and all safety notes of attachments supplied with the

joint cutter!

ATTENTION!

Only use genuine parts!

Only by using genuine parts or parts (spare parts) approved

by CEDIMA® the operational safety of the CF•22 E can be

guaranteed.

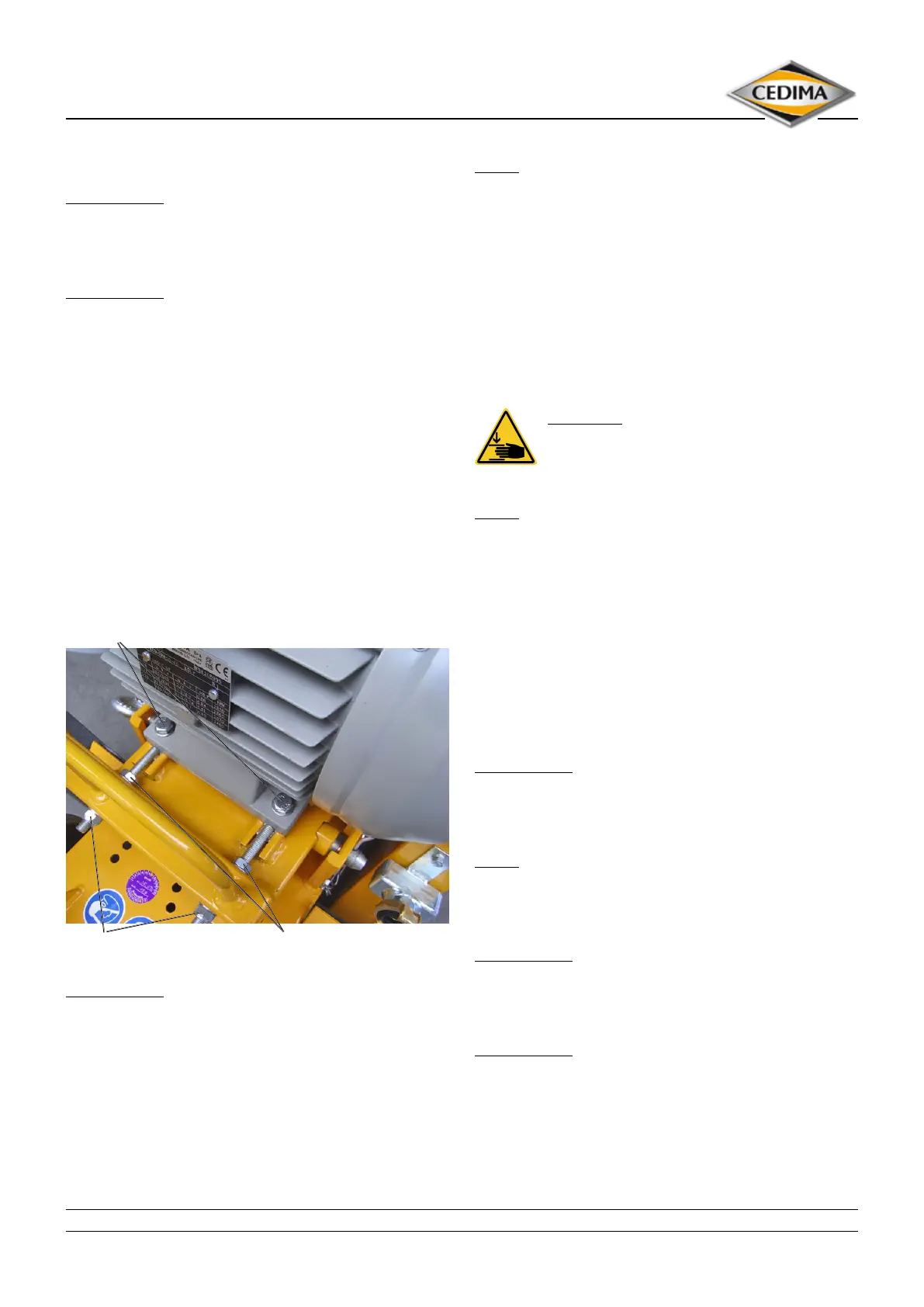

5.7.1 Adjusting the tension of the V-belts

For tensioning the V-belts slightly loosen the two motor x-

ing screws (g. 5.1). Pull the motor backwards with the helb

of the two tensioning screws mounted on the rear side of

the motor. While doing this, check the tension of the belts.

After the correct belt tension has been achieved, retighten

the lock nuts of the tension screws and the motor xing

screws.

Clamping nut Lock nut

Figure 5.1

Motor xing screws

ATTENTION!

Tighten the nuts of the clamping screws evenly!

Unevenly tightened clamping nuts might lead to canting of

the motor suspension plate and consequently of the motor

and V-belt pulleys on the motor shaft.

The V-belts are running at the edges of the V-belt pulleys and

wear more quickly. A sudden rupture with negative conse-

quences for the diamond saw blade and the motor cannot be

excluded!

NOTE

An even tightening of the clamping nuts can be obtained by

turning the nuts alternately each one turn!

– Check the tension of the V-belts (refer to section 4.1.3).

5.7.2 Changing the V-belts

The V-belts should and/or have to be replaced, when

further tensioning is no more possible and when they are

damaged (frayed, porous, …).

DANGER!

Risk of jamming and crushing during chang-

ing of the V-belts! Watch out for hands and

ngers!

NOTE

The belts shoud always be changed together, so a equally

tensioning and power transfer is possible.

Depending on the right or left cutting side, dismantle the

blade guard or the cutting shaft protection rst (g. 4.3).

After dismounting the V-belt cover (g. 4.3) the V-belt drive

is exposed.

Relax the V-belts as described in sect. 5.7.1, remove the old

belts and place the new.

Tighten the cutting shaft V-belts and mount the V-belt

cover and the blade guard resp. cutting shaft protection.

ATTENTION!

Do not use any sharp or pointed objects for changing the

V-belts in order to prevent damages that might destroy

the V-belts.

NOTE

Turn the pulleys of the cutting shaft and the motor and move

the V-belts diagonally across the pulley grooves until all V-

belts are parallel.

ATTENTION!

Do not overstretch the V-belts (1,5% wear limit)! The

V-belt can break and the cutting shaft bearings and

motor bearing will be destroyed otherwise.

ATTENTION!

New V-belts have to be checked for correct tension and,

if necessary, be retensioned at least after 10 operating

hours!

Loading...

Loading...