Do you have a question about the Challenger Lifts 24012 E and is the answer not in the manual?

Determine location, check clearance, prepare floor, and mark site layout.

Bolt cylinder beam to main posts and lift upright.

Plumb and anchor front post, align, and tighten beam bolts.

Install cross rails, pull chains, and attach to main posts.

Install safety rod and attach lifting chains to cross rail connectors.

Attach power unit, hose, wire to circuit, fill reservoir.

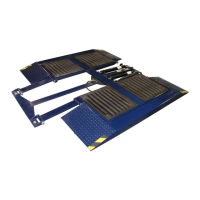

Level cross rails and position runways.

Position off side posts, plumb, and check alignment.

Test lift travel, safety latch operation.

Anchor off side posts, install chocks and ramps.

Cycle lift to bleed air and install anti-sway devices.

Demonstrate operation, review safety, complete warranty.

Activate slip plates, install ball bearings, attach L-pins.

Attach L-pins and leveling leg assemblies.

Install stop bolt on jack rail.

Install walk platform, gate lock, post, and gates.

Assemble ladder, attach to rack, install railing.

Install drive-through ramps.

Ensure concrete cure time and wear safety glasses.

Drill holes, clean, install anchors, and tighten nuts.

Ensure operator training and availability of manufacturer's literature.

Display operating instructions and establish regular maintenance schedules.

Implement lockout/tagout for repairs and prohibit unauthorized modifications.

Steps for driving onto lift, raising, and engaging safety latch.

Steps for lifting off safety latch, releasing, and lowering the lift.

Inspect anchor bolts, fluid leaks, and connections. Check torque.

Check the fluid level in the power unit reservoir.

Check cross rail and lift chains for wear, tension, and lubricate.

Common causes include blown fuse, hydraulic issues, or low oil.

Issues related to obstructions or safety latch not releasing.

Potential causes are debris in the lowering valve or travel stop issues.

Primarily caused by insufficient hydraulic oil level.

| Brand | Challenger Lifts |

|---|---|

| Model | 24012 E |

| Category | Lifting Systems |

| Language | English |

Loading...

Loading...