User Instructions

Note: All warnings and cautions denoted throughout this user’s manual also apply to the modifi cations listed below. Gen-

eral instructions and specifi cations referring to the open and closed loop systems apply to the fi eld-modifi ed units below.

Appendix B

microTHERM™: CMX Closed Loop to Open Loop Cooling Conversion

This sheet details the steps taken and material required to convert a Chromalox CMX microTHERM hot

water system from closed loop cooling to open loop cooling. The basic operation involves removing the

heat exchanger bundle and replacing it with a fl at plate. Please contact the Chromalox Customer Service

department for more information and to order the necessary materials.

New Material Required

1. 1/4” NPT Pipe Plug 1 piece Chromalox part number 218-075439-036

2. 1/4” NPT x 1-1/2” Nipple 1 piece Chromalox part number 198-122817-013

3. 1/4” NPT Elbow 1 piece Chromalox part number 107-122815-001

4. 1/4” NPT Close Nipple 1 piece Chromalox part number 198-122817-002

5. 1x1/2” NPT Reducer 1 piece Chromalox part number 032-120942-019

6. Open loop cooling fl ange 1 piece Chromalox part number 121-510702-017

Replacement Steps

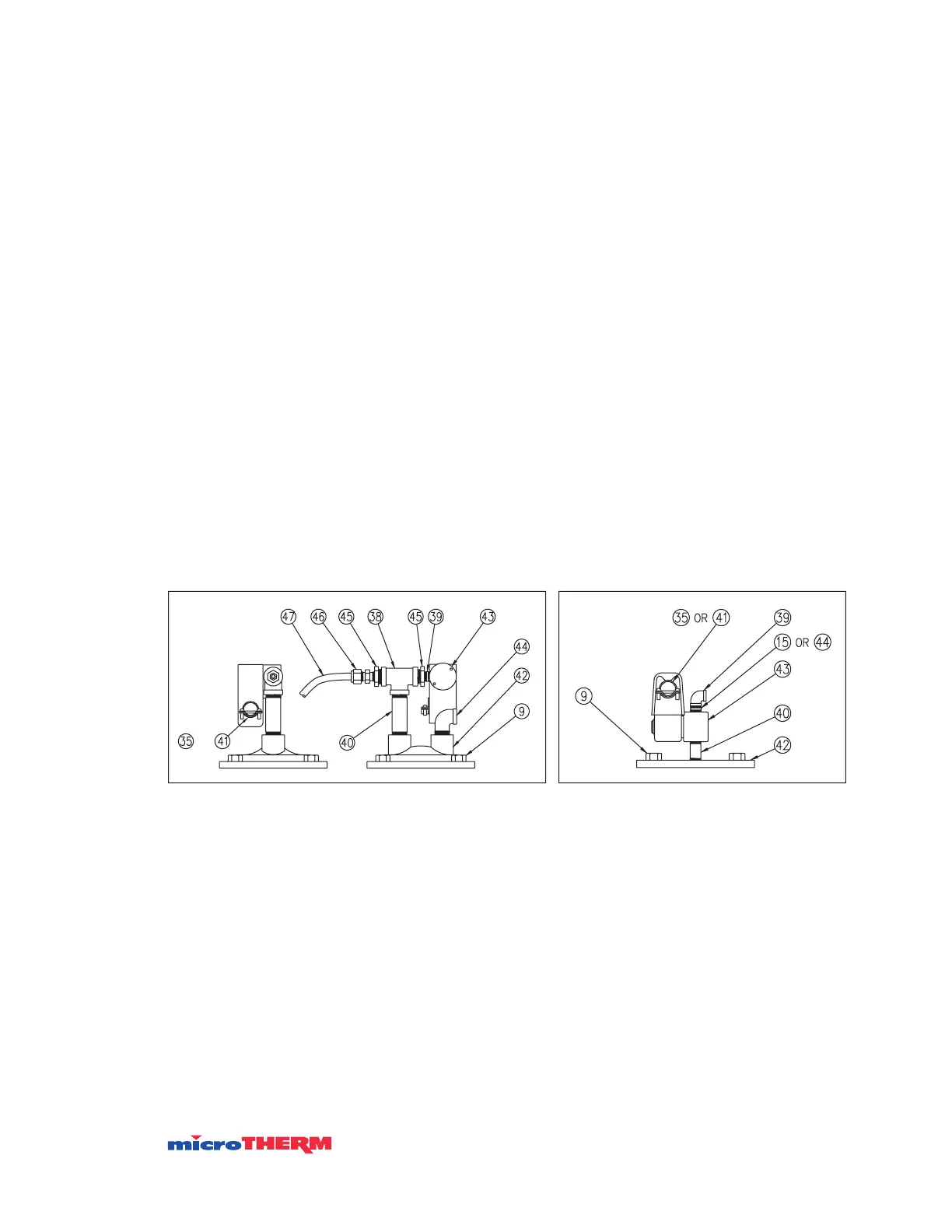

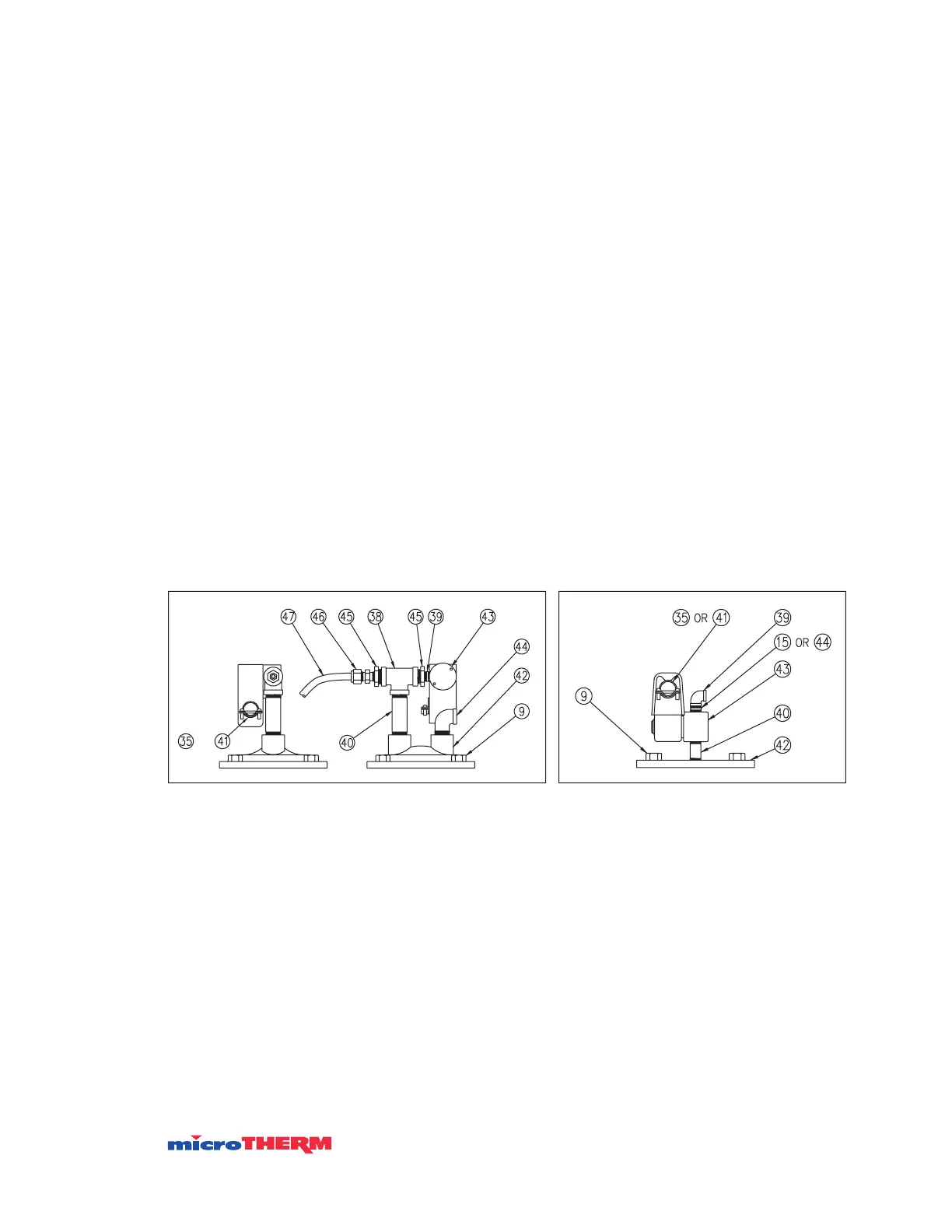

Figures 1 and 2 show the layout of the cooling confi guration for both closed and open loop cooling. These

parts are located on the top of the cooling chamber. Use pipe tape or other sealing compound when

attaching threaded connections.

Note: Refer to Figures 3 and 4 for location of components.

1. Remove (47) 3/8” copper tube and compression fi ttings from heat exchanger and tee above pump inlet.

2. Place 1/4” pipe plug into tee above pump inlet where copper tube was connected.

3. Pop magnetic coil from top of (43) solenoid valve and leave wired to system.

4. Remove (43) solenoid valve from top of heat exchanger and keep for reinstallation.

5. Remove four (9) bolts and lift (42) heat exchanger from cooling chamber.

6. Reuse rubber gasket and (9) bolts to attach new (42) cooling fl ange to cooling chamber.

7. Attach new (40) 1-1/2” nipple to fl ange.

8. Attach (43) solenoid and magnetic coil to nipple.

9. Attach new (15) close nipple and new (39) elbow to solenoid.

10. Replace 1” pipe plug from lower cooling chamber port with 1 x 1/2” reducer.

11. Lower cooling chamber port becomes the new cooling inlet.

Figure 1: Closed Loop Cooling Figure 2: Open Loop Cooling

or

43

Loading...

Loading...