OPERATION No MA. 390-O :

ChrckinR thr bydraalir co’mponcnts on the u&i&

f Manual stcprine r~ebidos t

Op. MA. 390.0

1

CHECKING’THE HYDRAULIC COMPONENTS

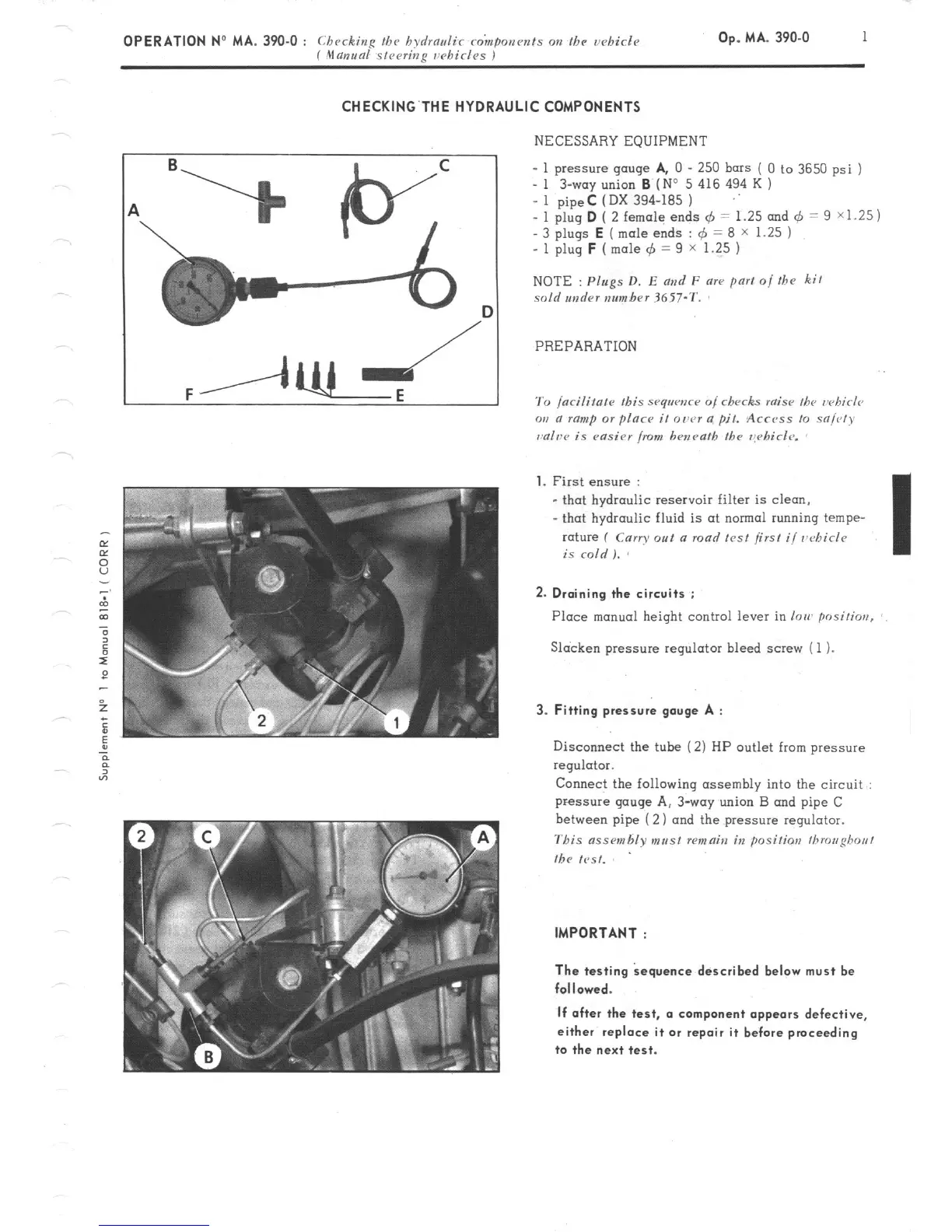

NECESSARY EQUIPMENT

- 1 pressure gauge

A,

0 - 250

bars ( 0 to 3650

psi

)

_ 1 3-way union B (No 5 416 494 K 1

- 1 pipeC (DX 394-185 ) ..

- 1 plug D ( 2 female ends 4 1.25 and 6 9 X1.25) = =

- 3

plugs

E (mole

ends : r$ 8 X 1.25 ) =

- 1 plug

F (

mole 4 = 9 x 1.25 1

NOTE

: Plugs D, E md

F are part 01 fhe kit

sold snder number 3657-T.

PREPARATION

1.

First ensure :

- that hydraulic reservoir filter is clean.

- that hydraulic fluid is ot normal running tempe-

rature ( Carry 0~1 a road lent first i/ vt4icie

is

mid ). 8

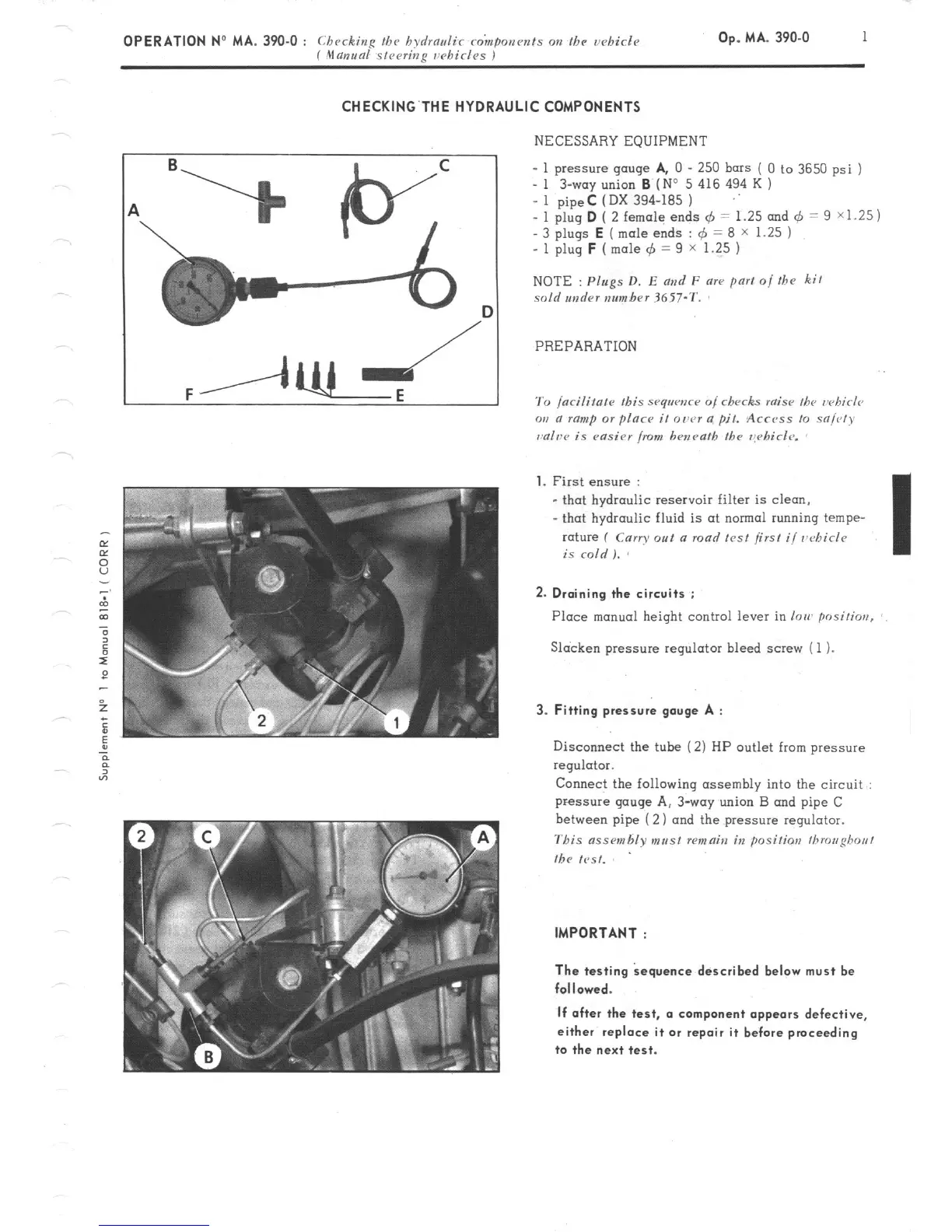

2. Draining the circuits :

Place manual height control lever in ion,

posirios,

Slacken pressure regulator bleed screw ( 1 ).

3. Fitting pressure gouge A :

Disconnect the tube (2) HP outlet from pressure

regulator.

Connect the following assembly into the circuit :

pressure gaoge A, 3way union B and pipe C

between pipe ( 2) and the pressure regulator.

This ass~nzhly mrtst remain in positioa /brougbo~~l

the test.

IMPORTANT :

The testing kquance described below must be

followed.

If after the test, a component appears defective,

either replace it or repair it before proceeding

to the next test.

Loading...

Loading...