OPERATION No MA. 02 : I+ 4’ 0, “‘g 01, Ill<, l1\~c!).ollli(- s\‘sfell~.

Op. MA. 02

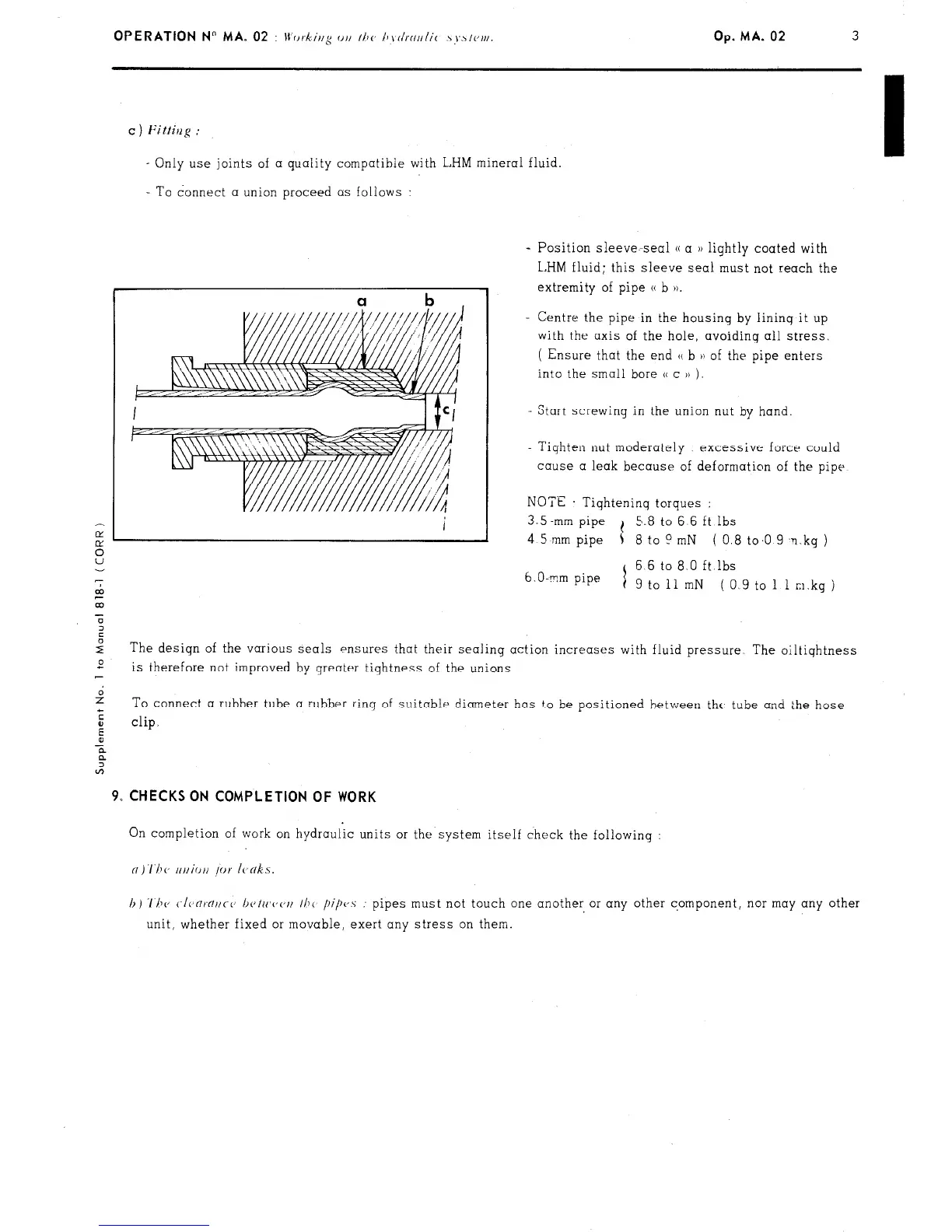

I To connect a union proceed as follows :

- Position sleeve-seal (( a u lightly coated with

L,HM fluid; this sleeve seal must not reach the

extremity of pipe (( b )).

- Centre the pipe in the housinq by lininq it up

with the axis of the hole, avoidinq all stress.

( Ensure that the end u b )I of the pipe enters

into the smali bore C< c )> j.

Start screwing in the union nut by hand.

- Tiqhten nut moderately : excessive force could

cause a leak because of deformation of the pipe

NOTE Tiqhteninq torques :

3.5 -mm pipe t 5.8 to 6 6 ft lbs

4 5 mm pipe

5 8 to 0 mN ( 0.8 to.0 9 ‘1 kg )

6 6 to 8 0 ft.lbs

6. O-mm pipe

1

9 to 11 mN (0 9 to 1 1 m.kg )

c ) Fittilzg :

I Only use joints of a quality compatible with LHM mineral fluid.

The design of the various seals ensures that their sealing action increases with fluid pressure The oiltiqhtness

e

is therefore not improved by greater tiqhtness of the unions

2

To connect a rubber tube a rubber rinq of suitabie diameter has to be positioned between thr, tube and the hose

:

E

clip.

0

x

a

A

9, CHECKS ON COMPLETION OF WORK

On completion of work on hydraulic units or the system itself check the followinq :

h) ‘1’11~ C./CJ~~~IIC-C, I~c,lrt,c,c,rt I/J<

pipvs

: pipes must not touch one another or any other component, nor may any other

unit, whether fixed or movable, exert any stress on them.

Loading...

Loading...