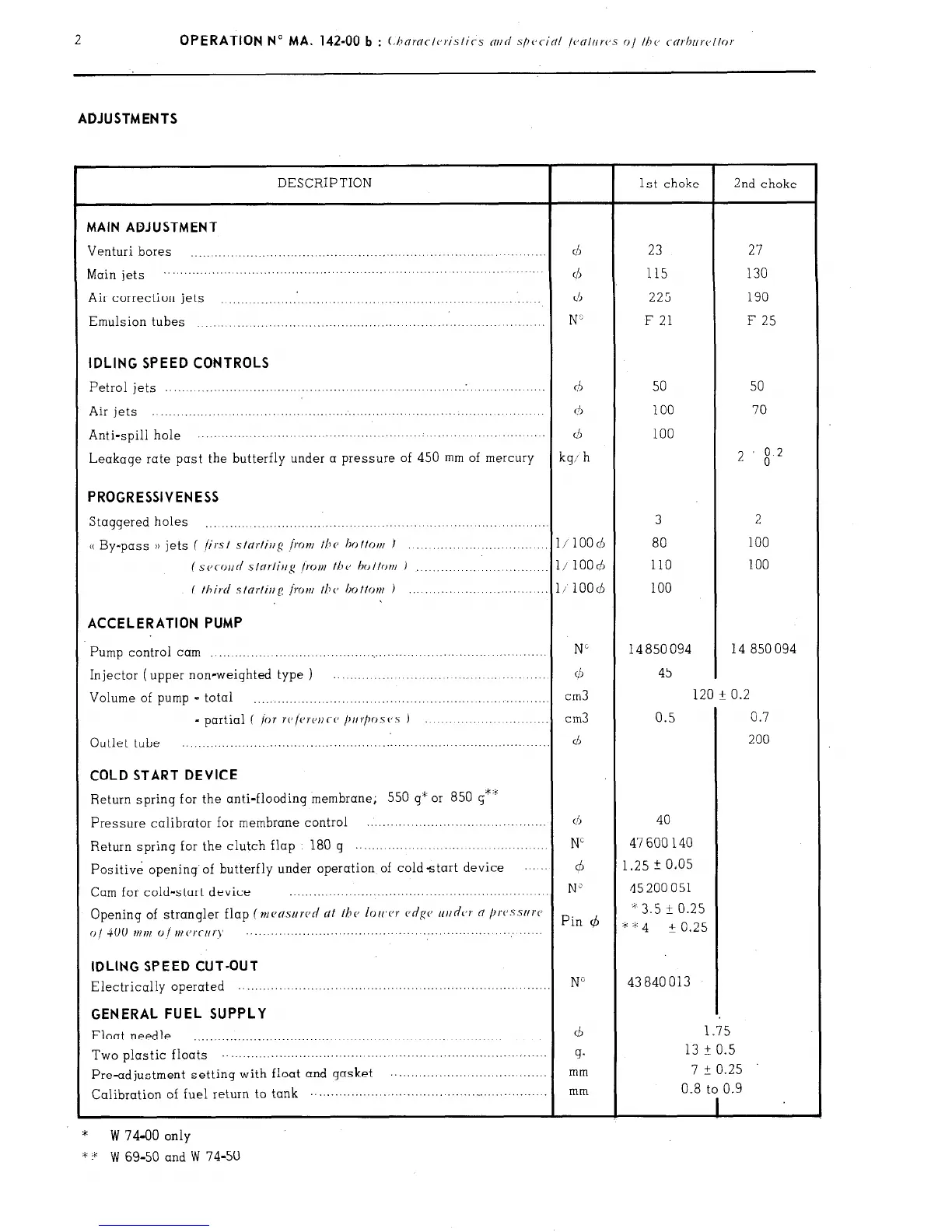

ADJUSTMENTS

DESCRIPTION

1st choke

2nd choke

MAIN ADJUSTMENT

Venturi bores

...................................................................................

d

23

27

Main jets

................. ...........................

... ................. ... ....... ...............

cl5 115 130

Air correction jets ..............................................................

d 225 190

Emulsion tubes

...............................................................

......

N’

F 21

F 25

IDLING SPEED CONTROLS

Petrol jets

.......................................................................................

d

50 50

Air jets .....................................................................................

(3

100 70

Anti-spill hole

............... ..............................................

....... ........

d 100

Leakage rate past the butterfly under a pressure of 450 mm of mercury

kg; h

2

$2

PROGRESSIVENESS

Staggered holes 3

2

...............................................................................

u By-pass )) jets (

/irst stnrtiug /row the

ho ttott/ J

100 ............................ 1 / 100 cb 80

( SC~COII~ slnrlirrg I.0Nf the bottom )

......................

l/ 1OOd 110 100

( third stnrfiug [row the bottov~ )

...........................

l/100($

100

ACCELERATION PUMP

Pump control cam N”

14 850 094 14 850 094

...............................................................................

Injector ( upper non-weighted type ) ............................................

d 45

Volume of pump - total

cm3

120 -t 0.2

.......................................................................

- partial ( /or r(‘/vre)~Co /~IIr/wS(‘S )

................... ...........

cm3 0.5

0.7

Outlet tube

200 ................................................. ....... ...........

............... ...

d

COLD START DEVICE

Return spring for the anti-flooding membrane; 550 g” or 850 g*‘i;

Pressure calibrator for membrane control

...........................................

(1, 40

Return

spring

for the clutch flap

180 g ...............................................

Ni

47 600 140

Positive opening’of butterfly under operation of coldstart device

.... d

1.25 2 0.05

Cam for cold-start device

N”

45 200 051

..............................................................

Opening of strangler flap (mensllrcd

dt

the loIc,cr c,dgc’ ur/dcJT 0 /lI’(‘.sSlI)‘C

* 3.5 i 0.25

() j 4(j(J tr ,),, (J ,,, (Jr(-[,q

Pin (b

““4 -t 0.25

..... ... .....................................................

... ......

IDLING SPEED CUT-OUT

Electrically operated NG 43840013 .............................................................................

GENERAL FUEL SUPPLY

Float needle

d

1.35

..................................................................................

Two plastic floats

13 F 0.5 ...................................

............... .............................

g.

7 t 0.25

Pre-adjustment setting with float and gasket

...............................

....... mm

Calibration of fuel return to tank

.................................

......................... mm 0.8 to 0.9

1

*

W 74-00 only

* + W 69-50 and W 74-50

.

Loading...

Loading...