11

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

THE RUNNING GEAR

The Running Gear is protected by a cover (22), which is removed by

unscrewing the two securing hex screws.

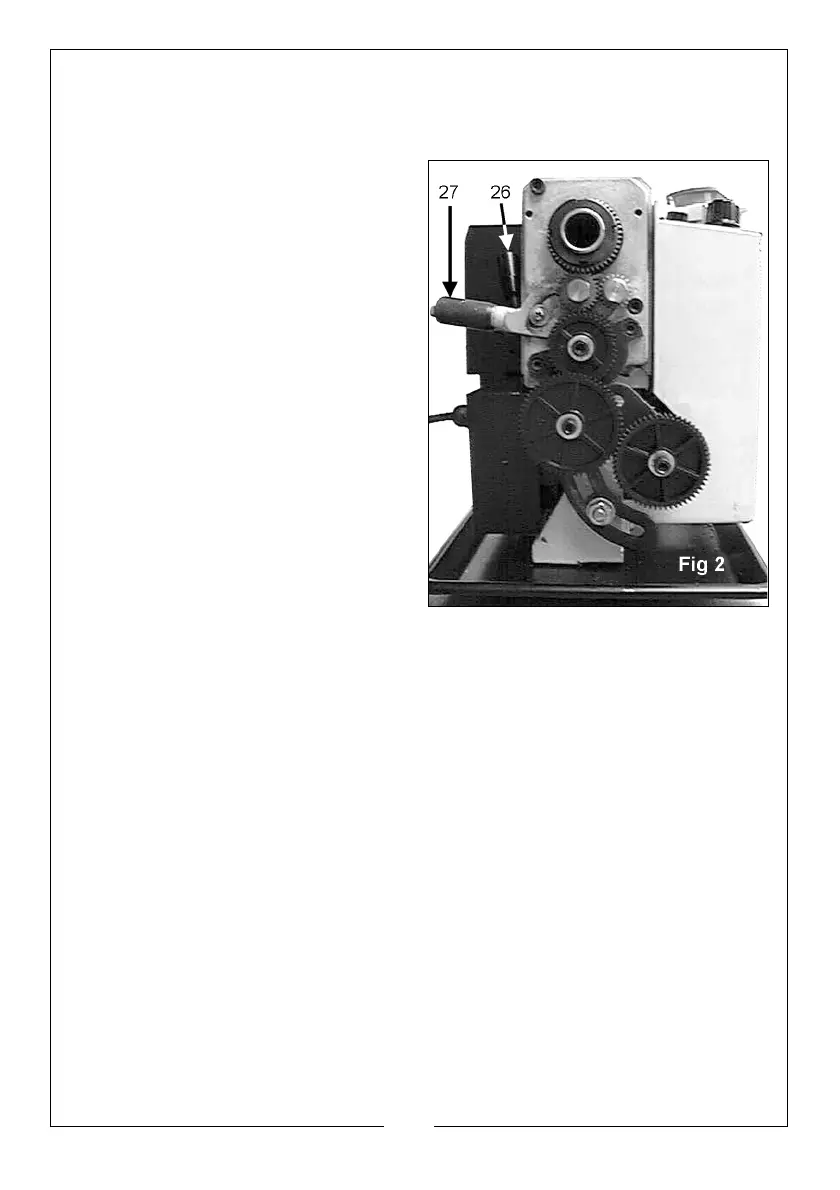

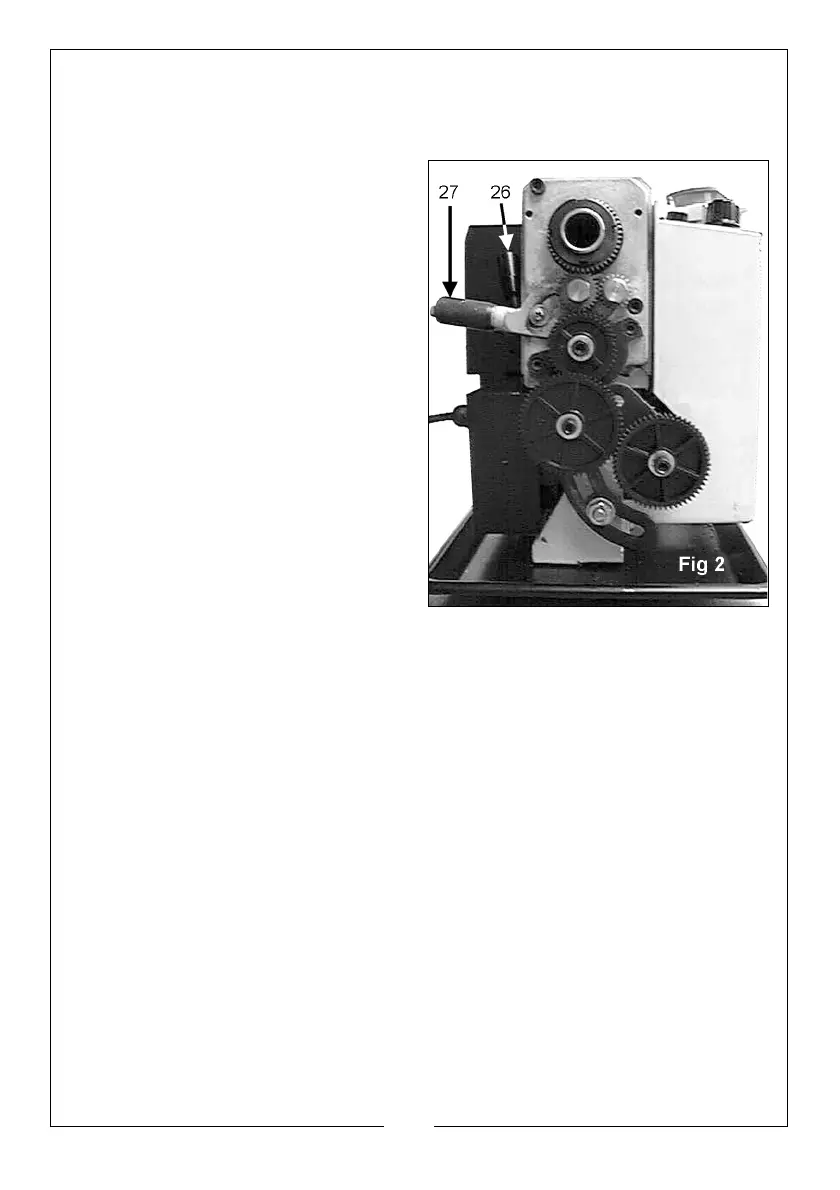

The gear train is shown in Fig. 2. It

transmits drive to the lead screw

which acts as a worm gear and by

operating the Auto Feed Lever (15),

which engages a nut with the lead

screw (worm), drive is transmitted to

the saddle and consequently the

cutting tool. This provides a power

feed for screw cutting or general

turning operations.

The rotational speed of the lead

screw and hence the rate of feed of

the cutting tool, is determined by the

gear configuration. This is explained in

greater detail under ‘Screwcutting’

on page 20.

The drive to the leadscrew may be

disconnected by operating the lever

(27), which is also used to drive the

leadscrew in a forward or reverse

direction. (These actions are described in greater detail under ‘Screwcutting’

on page 20.

THE TAILSTOCK

The Tailstock (9), may be moved along the bed to any desired position and is

secured in position by a single nut (10), at its base. The Tailstock Spindle carries

an internal No.2 Morse taper for use with the Centre (8) provided.

A Revolving Centre and Drill Chuck are also available from your Clarke dealer.

(See Accessories on page 30).

THE SADDLE

The Saddle carries the Cross-Slide (6), on to which is mounted the Compound

Slide (7) with Tool Post (5), allowing intricate and delicate operations to be

performed. It may be driven by the Leadscrew, via a Drive Nut, to provide

automatic feed when the Auto Feed lever (15), mounted on the Apron (17), is

operated.

The position of the tool is effected by turning the cross-slide feed handle (16),

which moves it across the lathe and the saddle or manual feed handle (18),

which moves it longitudinally.

Loading...

Loading...