14

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

The hinged transparent chuck guard is supplied loose and must be fitted to

the headstock body using the screws provided.

The four rubber feet are attached to the underside of the bed using the four

M6 pan head screws in the tapped holes provided. These screws are also used

to secure the collecting tray. We strongly recommend however, that to

provide maximum stability and additional safety, you secure the lathe to a

firm foundation as described under ‘Mounting the Lathe’.

The three external jaws for the 3-jaw self centering chuck, extend the capacity

of the chuck and are discussed in greater detail under ‘Accessories’ on page

30.

MOUNTING THE LATHE

The lathe should be mounted on a strong, heavy workbench of sufficient

height so that you do not need to bend your back to perform normal

operations. Take the necessary precautions when moving the lathe

considering its’ weight. Assistance will be required.

Ensure the location is adequately lit and that you will not be working in your

own shadow.

We strongly recommend that the machine is bolted firmly to a strong

workbench using the tapped holes used to secure the feet to the lathe. This is

to provide added stability and therefore additional safety.

To do this, remove the four M6 screws which secure the rubber feet and

collection tray to the machine (if already fitted) and discard the feet.

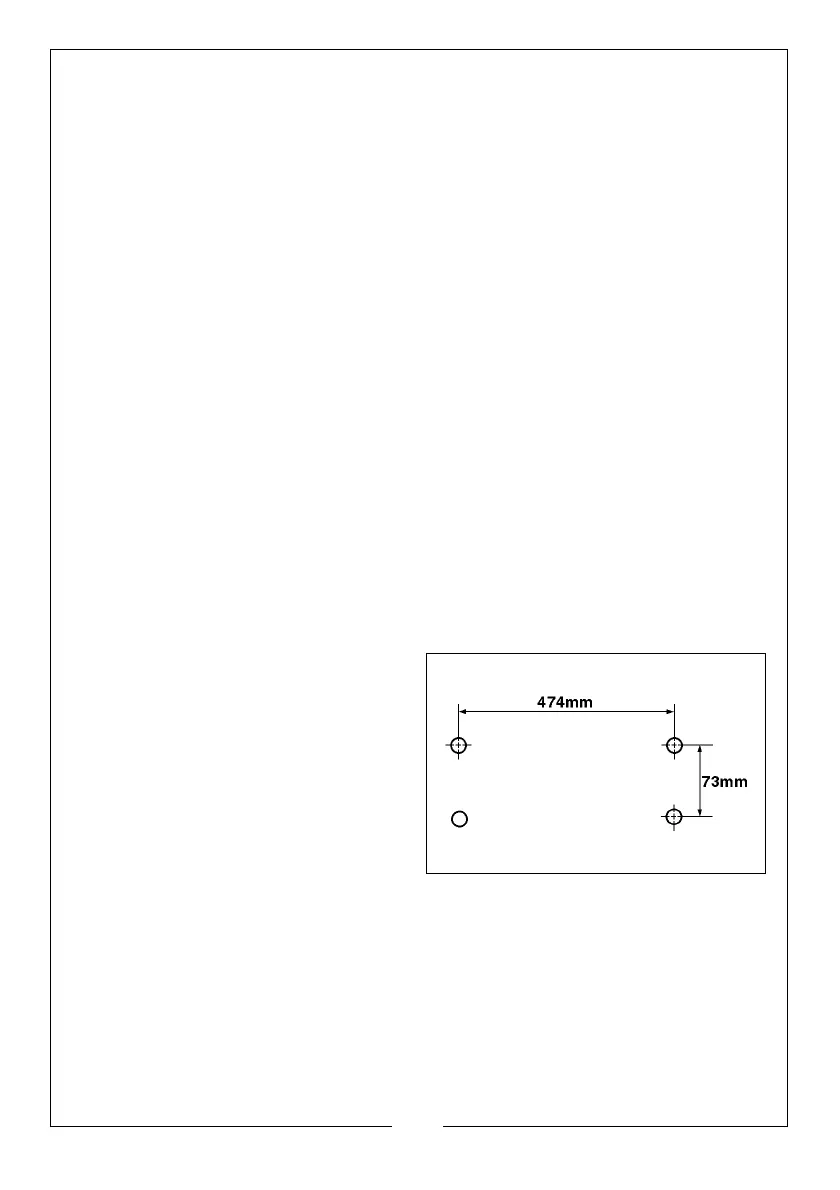

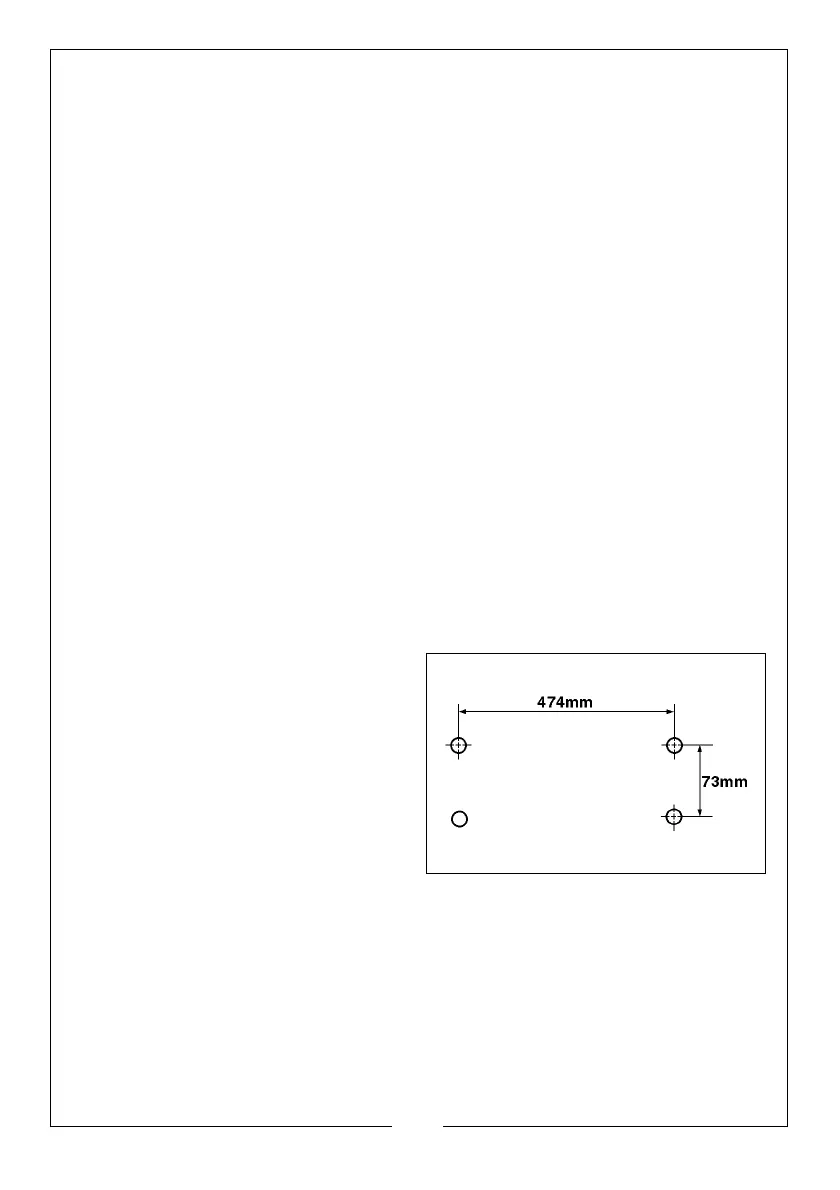

Drill four M6 clearance holes in a

worktop, at the dimensions shown in

the diagram, and with appropriate

length M6 bolts, or screws with flat

washers, (not supplied), secure the

lathe to the worktop ensuring the

collection tray is in place.

Alternatively, if you do not want a

permanent installation, you may

secure the lathe to a 5/8” thick

plywood board with a minimum recommended dimension of 800 x 300mm,

the mounting holes being centralised on the board.

When the lathe is in use the board should be clamped to workbench using

‘G’ clamps.

Loading...

Loading...