17

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

OPERATION

SIMPLE TURNING

Before starting the machine, it is imperative that the setup for the type of work

to be carried out is fully checked.

The following notes are guidelines as

to how to set up the lathe in order to

carry out a simple turning operation.

ALWAYS plan your work. Have

drawings or a plan on hand together

with any measuring instruments you

may require, such as micrometers/

verniers/calipers etc.

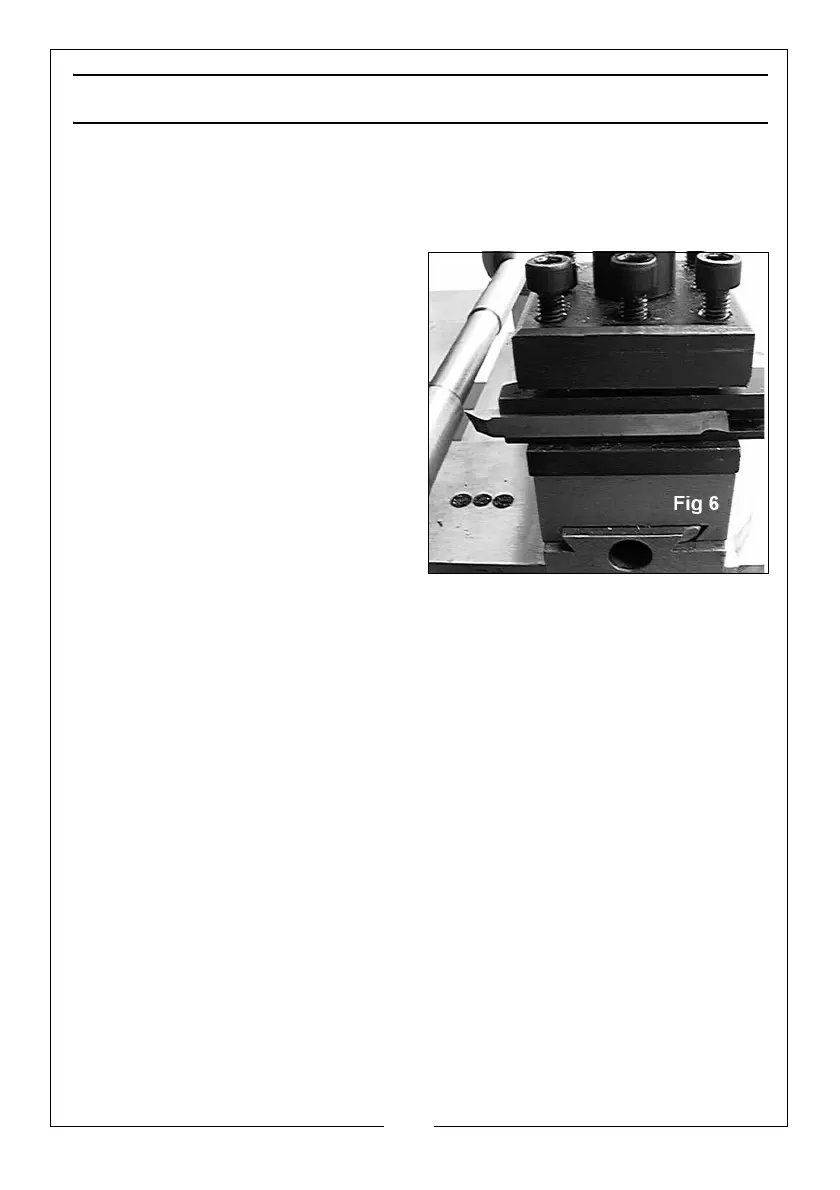

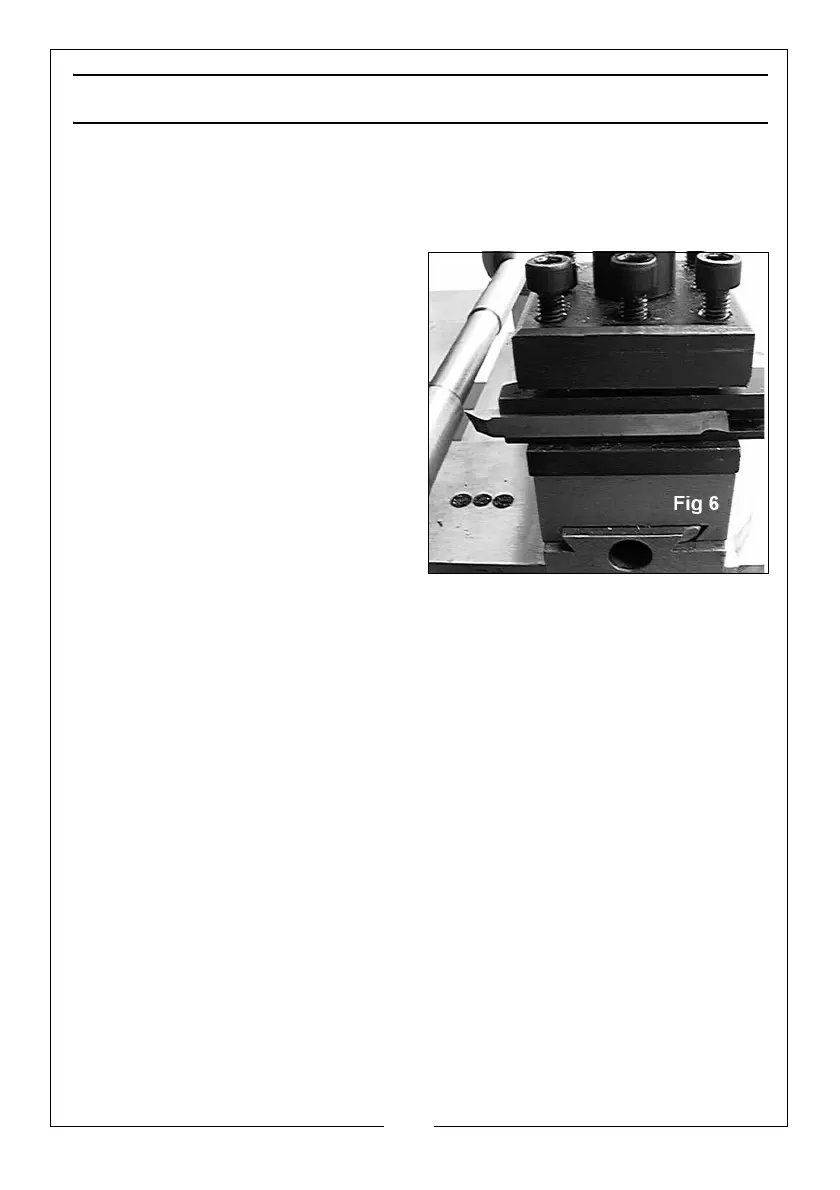

Select a cutting tool that will produce

the desired cut and mount it in the

Tool Rest, with as little overhang as

possible, securing it using three hex

socket head screws as shown in FIG. 6.

(Ideally, the overhang should be

approx. 10 mm but not more than 15mm for a straight tool).

It is essential that the tip of the cutting tool is on the centre line of the work or

very slightly below it. On no account should it be above the centre line. Where

necessary, shims should be used beneath the tool in order to achieve the

correct height, or, if the tip is too high, the only recourse is to select another

tool or grind down the tip.

To check to ensure the tip is at the correct height, position the tool so that the

tip is almost touching the point of the tailstock centre. They should coincide. If

necessary make adjustments using shims, grind down the cutting tool tip or

select another tool.

When satisfied, mount the work, either in the chuck or on a faceplate, and if

necessary, use the tailstock centre for additional support (If the work cannot

be adequately secured by the chuck, or if it is a long piece, or of small

diameter). Additionally, ‘Steadies’ may be used which are described in

greater detail under ‘Accessories’.

If the tailstock is not to be used you may remove it completely by slackening

off the securing nut at its base and sliding it free of the bed.

Mark the surface of the work at the point where the cut is to end, i.e. the

shoulder, using a scriber or similar means, and move the saddle so that the

cutting tool is directly opposite the mark, then wind in the cross-slide so that

the tool touches the surface of the work.

Loading...

Loading...