13

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

UNPACKING AND ASSEMBLY

On receipt, carefully unpack the lathe. Inspect to ensure that no damage was

suffered in transit and all parts are accounted for. Should any damage be

apparent or parts are missing, please contact your Clarke dealer immediately.

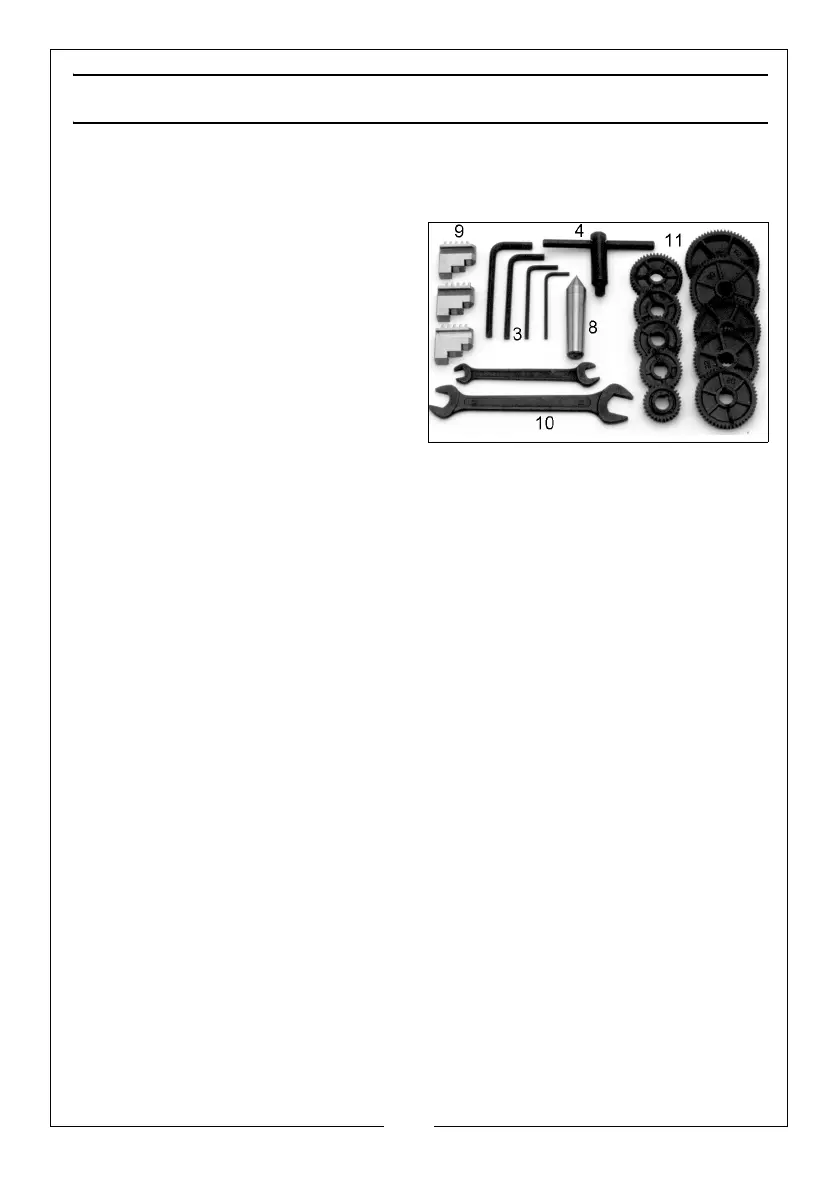

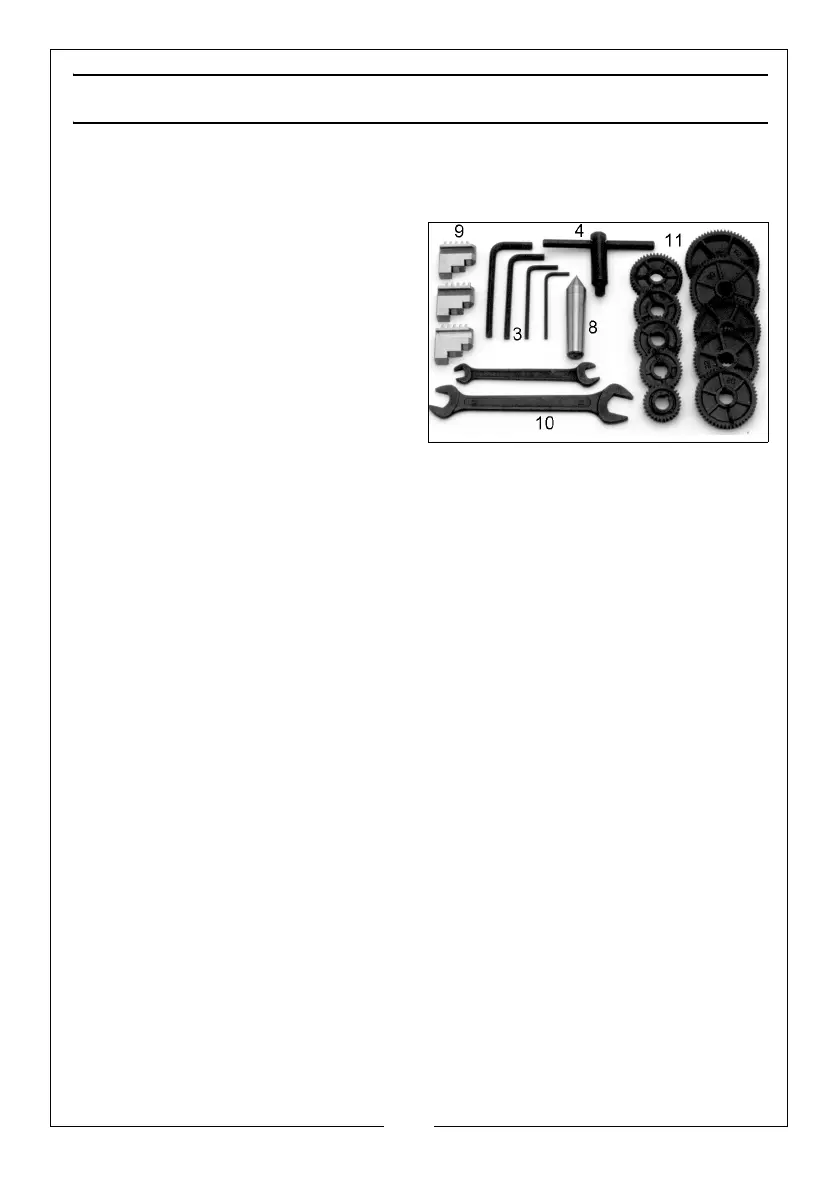

The following loose items are to be

found in the crate.

1. 4 x Rubber Feet*

2. 4 x M6 Pan Head Scews*

3. 4 x Hex. Keys

4. 1 x Chuck Key

5. 1x Plastic Oil Container*

6. 1 x Spare Fuse - 2 amp, glass type.*

7. 2 x Plastic Handles w/Nuts and Bolts.*

8. No.2 Morse Taper Centre (for Tailstock)

9. 3 x External Jaws (for 3-Jaw Chuck)

10. 2 x Double Open Ended Spanners 8x10mm and 14x17mm

11. 1 x Gear Set. Sizes: 30, 35, 40, 40, 45, 50, 55, 57, 60, 65 Teeth

* denotes not illustrated

With assistance, considering the weight of the lathe, raise it on to a robust

surface or workbench. Proceed to remove all traces of preservative with

paraffin or good quality solvent and lightly oil all machined surfaces.

You will notice that for transit purposes, the cross slide feed handle has been

mounted in reverse. Remove it, by unscrewing the hex. socket head screw

securing it and mount it the correct way round. Then turn all feed handles to

ensure they are free and move evenly and smoothly.

Attach the plastic handles to the rims of the manual feed and tailstock feed

handwheels respectively, ensuring the nuts are tight and the handles spin

freely about the bolts, without excessive end play.

The saddle, cross-slide and compound slide adjustments are all factory set to

ensure smooth movement in both directions. If however, the adjustments have

been upset during transit, indicated by stiff or erratic movement, refer to

‘Settings and Adjustments’ on page 28 for the methods of adjustment.

All hex. keys and spanners necessary to carry out various adjustments are

supplied, together with a chuck key for the 3-Jaw chuck and a spare 2 Amp

fuse. The fuse holder is located on the main control panel.

Loading...

Loading...