31

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

Replace them with the external jaws,

noting the following.

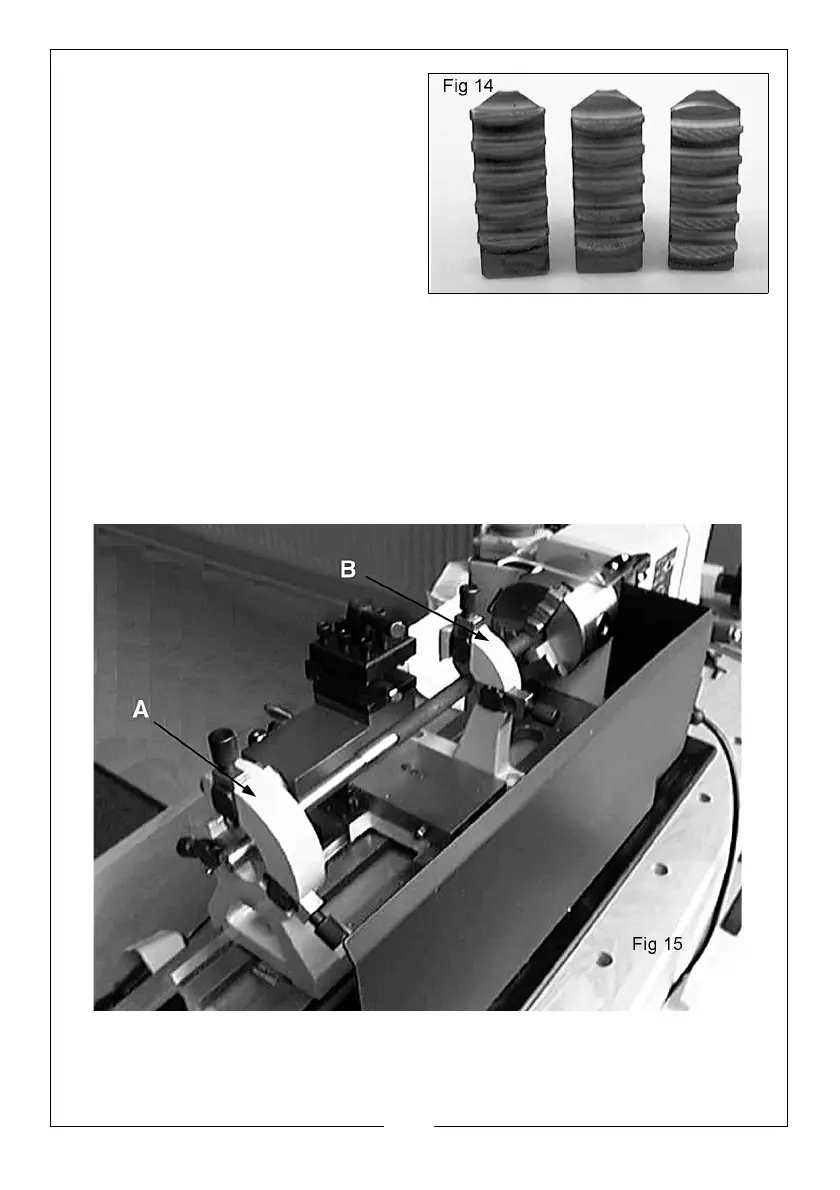

The thread segments of the jaws are

progressively ‘stepped’ as shown in fig

14. They are also numbered 1 to 3. This

is to take into account the lead of the

screw thread within the chuck. It is

therefore necessary to assemble the

jaws in the correct order.

Place them as shown in fig 14 and

assemble in the same order, clockwise in the slots in the chuck, turning the

chuck key as you insert them. Close the jaws fully and check to ensure they all

meet at the centre. If a jaw is out, open the jaws fully and retain pressure on

the jaw in question whist turning the chuck key until it snaps down into position.

Re-check to ensure all jaws meet at the centre.

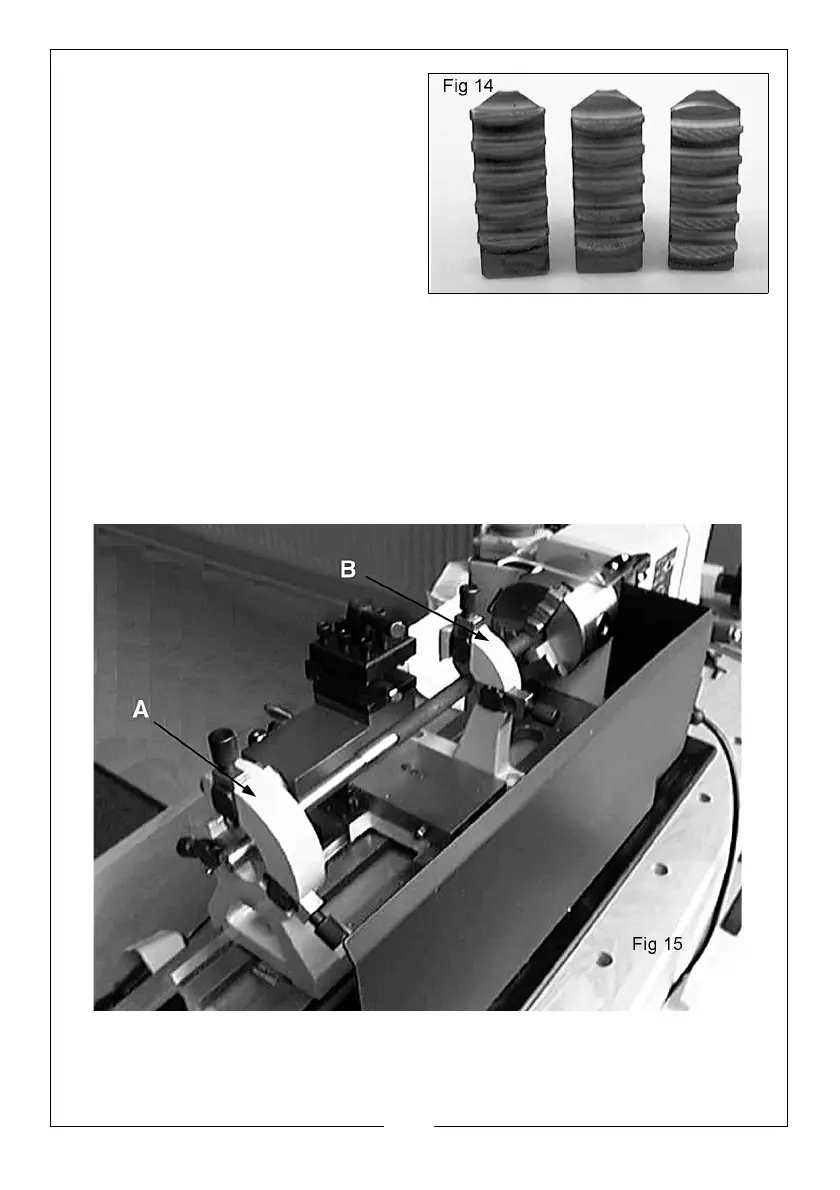

FIXED AND MOVING STEADIES

Fig 15, illustrates the Fixed Steady (A) and Moving Steady (B) assembled to the

lathe, used to support a long workpiece.

Loading...

Loading...