CFV Startup Guide

4 Part No. 750-288

1.2 Gas Piping

A manually operated shut-off valve and pressure regulator are provided

as standard on the Model CFV boiler. It is recommended to install an

approved gas filter or strainer in the gas supply line to the boiler. Please

inquire with the local gas supply company.

The boiler shall be installed such that the gas ignition system

components are protected from water (dripping, spraying, etc.) during

appliance operation and service.

If building supply gas pressure is greater than 1 psig (27.8” WC), an

upstream regulator with overpressure protection and proper gas venting

will be required and must be piped to a safe point of discharge.

All gas piping and components to the boiler gas train connection must

comply with NFPA 54, local codes, and utility requirements as a

minimum. Only gas approved fittings, valves, or pipe should be used.

Standard industry practice for gas piping is normally Schedule 40

black iron pipe and fittings.

See Table 1 for CFV gas pressure requirements.

1.3 Flue Gas Connection

The flue gases from the ClearFire boiler are removed via a gas-tight, temperature and corrosion resistant flue

gas pipeline. Only flue gas systems approved and tested by the relevant region or province are to be connected

to the ClearFire boiler. Refer to flue piping manufacturer for proper installation and sealing instructions.

See also Chapter 3 in the CFV Operation and Maintenance manual.

Boiler room ambient conditions

Relative humidity

< 85% non-condensing

Ambient temperature range 0

o

C to 50

o

C / 32

o

F to 122

o

F

Storage temperature range -20

o

C to 60

o

C / -4

o

F to 140

o

F

Combustion air temperature 0

o

C to 50

o

C / 32

o

F to 122

o

F

Specifications

Input power 115 VAC single phase 60Hz

Recommended operating steam

pressure

75-135 psig

Gas pressure requirements See Table 1

Table 1 CFV gas pressure requirements

Boiler HP Minimum pressure required

at gas train connection

Max. pressure

9.5 7.2" w.c.

28” w.c.

10 7.2" w.c.

15 7.3" w.c.

20 7.5" w.c.

25 7.7" w.c.

30 8.5" w.c.

40 11.0" w.c.

50 10.0" w.c.

60 10.0" w.c.

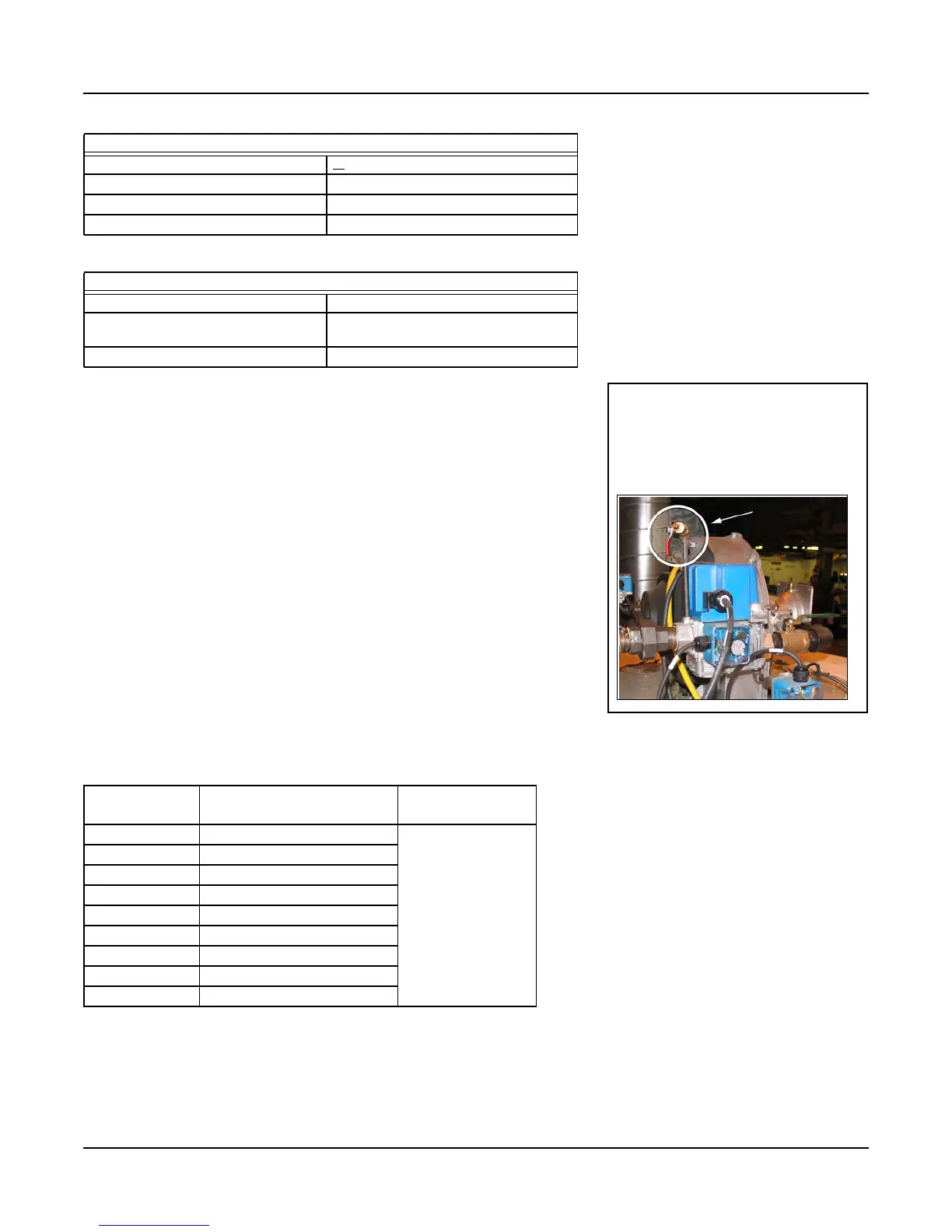

Note: To measure supply pressure

at the CFV gas valve, use the

test port on the valve inlet

flange (see below). Do not

use the leak test cocks to

measure gas pressure.

Loading...

Loading...