Section 2 — Installation

2-4 Part No. 750-263

3. Casing assembly

To assemble the CFC casing, the following tools are required:

1. Remove all packing material and open all boxes shipped with the boiler.

2. Remove all casing panels from box and group like pieces together for easy

access.

3. Locate boiler legs and attaching nuts/bolts (Figure 2-2). Ensure all four

leg height adjusters are at the same level before installing legs.

4. Remove the wooden skid cross beam from the front of the boiler

5. Using an appropriate jack, lift up the front of the boiler.

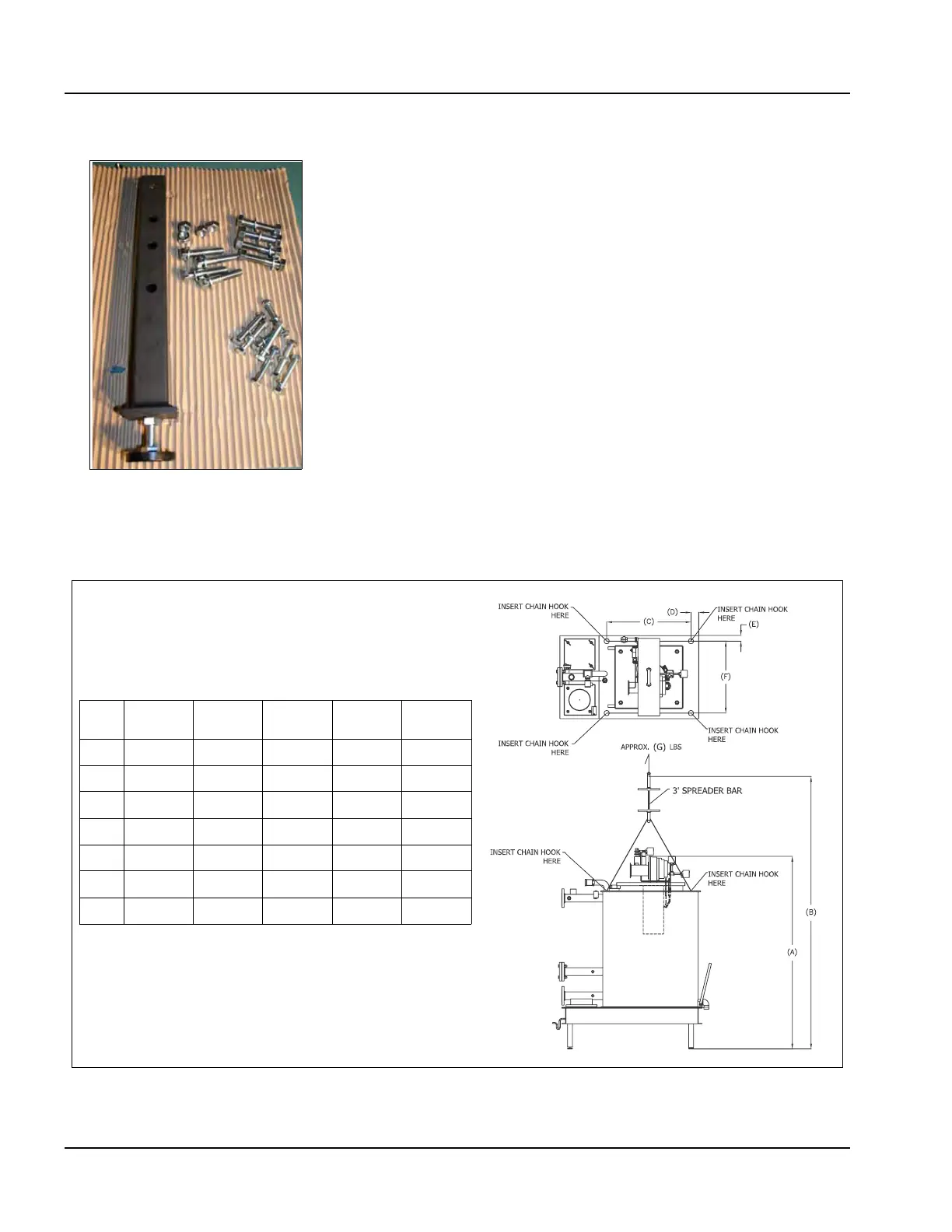

Note: A crane or fork lift may also be used to lift the boiler. When using a

crane, observe the rigging arrangement shown in Figure 2-3. To install

the boiler legs, first lift boiler, then remove and discard the wooden

base. Install legs and position the boiler. Proceed with step 10 below.

Figure 2-2

Flat head screwdriver

Phillips screwdriver

Cordless screwdriver

Utility knife

Crescent wrench

Machine head screw bit

Diagonal cutters

Fork lift or pallet jack

Socket wrench

10mm socket

13mm socket

19mm socket

6” socket extension

Zip-ties

Sheet metal screws

Figure 2-3 CFC Standard Rigging Arrangement

CFC

SIZE

500/750 1000 1500 1800 2500

A 70.625” 82.875” 74.875” 82” 84”

B 118.625” 130.875” 122.875” 130” 132”

C 20.5” 33.5” 32.625” 32.625 37.375”

D 3.15” 1.97” 2.76” 2.76 3.94”

E 3.15” 1.97” 2.76” 2.76 3.94”

F 20.5” 33.5” 32.625 32.625 37.375”

G 1477 lbs 1554 lbs 1940 lbs 2061 lbs 3600 lbs

Loading...

Loading...