BOILER BOOK CFC-E ENGINEERING DATA

38

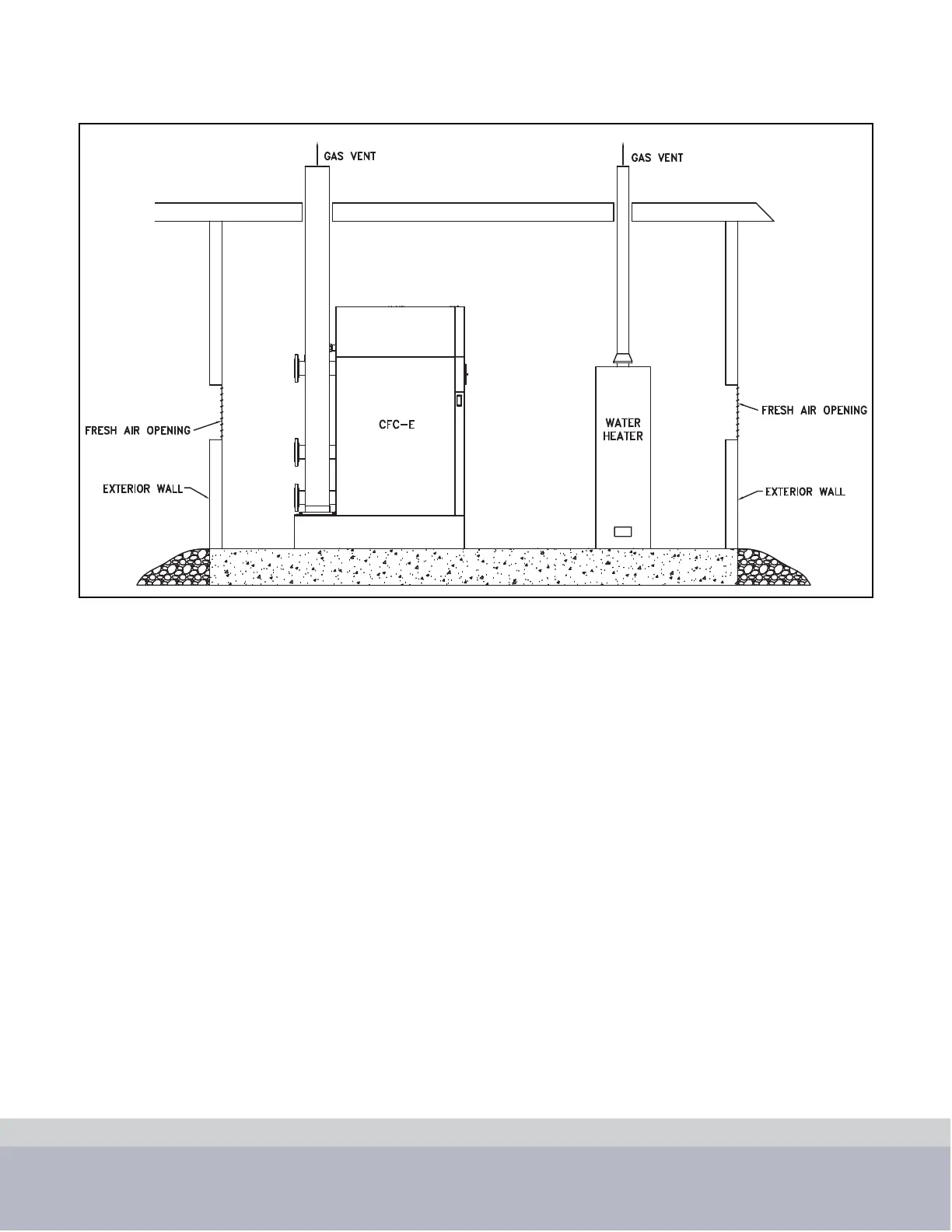

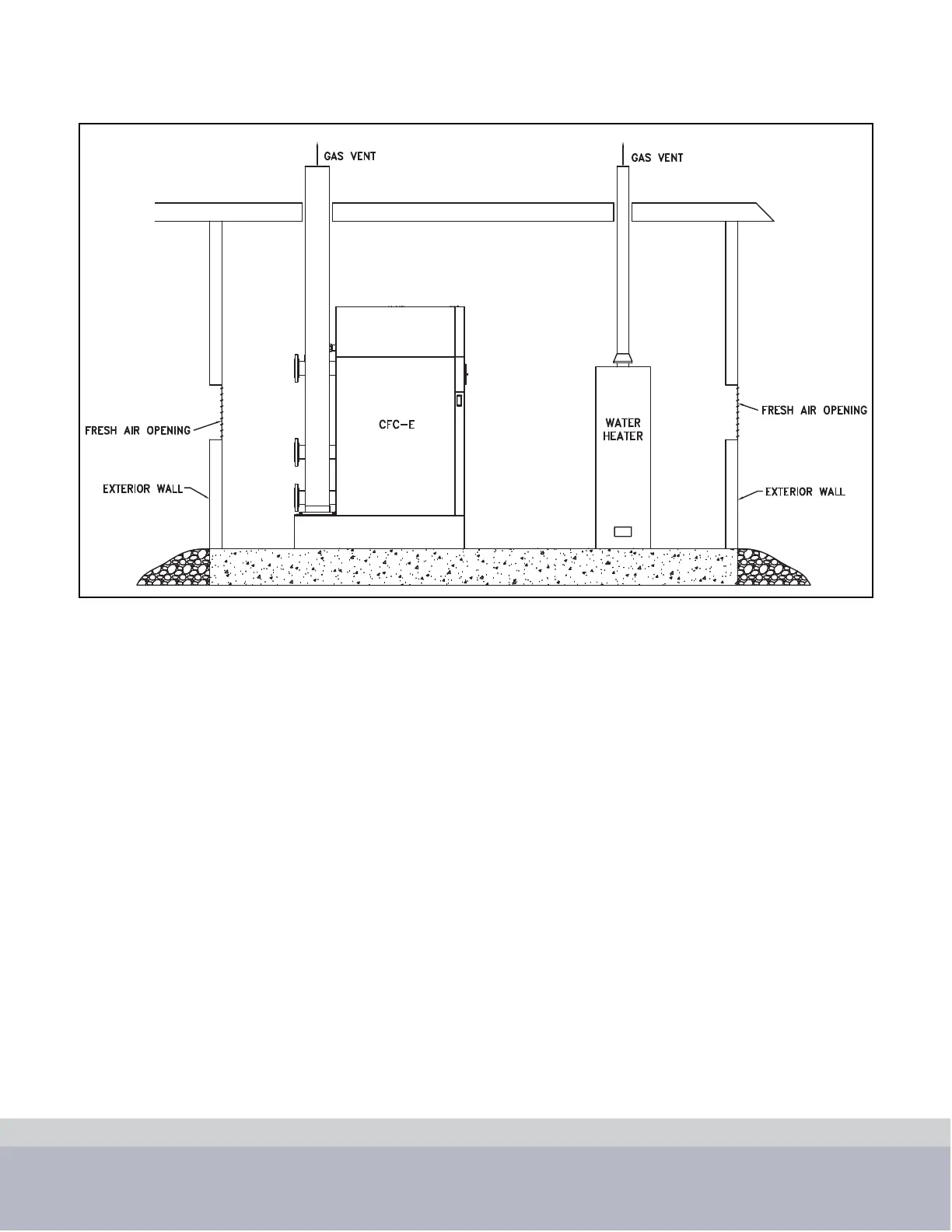

Figure 30. Two Opening Engineered Method

E. Size the openings by using the formula:

Area in square feet = cfm/fpm

Where cfm = cubic feet per minute of air

Where fpm = feet per minute of air

2. Amount of Air Required (cfm).

A. Combustion Air = 0.25 cfm per kBtuh.

B. Ventilation Air = 0.05 cfm per kBtuh.

C. Total air = 0.3 cfm per kBtuh (up to 1000 feet elevation. Add 3% more per 1000 feet of

added elevation).

3. Acceptable air velocity in the Boiler Room (fpm).

A. From floor to 7 feet high = 250 fpm.

B. Above 7 feet above floor = 500 fpm.

Example: Determine the area of the boiler room air supply openings for (2) Clearfire 1800 boilers at

750 feet elevation. The air openings to be 5 feet above floor level.

• Air required: 1800 x 2 = 3600 kBtuh. From 2C above, 3600 x 0.3 = 1,080 cfm.

• Air Velocity: Up to 7 feet = 250 fpm from 3 above.

• Area required: Area = cfm/fpm = 1,080/250 = 4.32 square feet total.

• Area/Opening: 4.32/2 = 2.16 sq-ft/opening (2 required).

Consult local codes, which may supersede these requirements.

Loading...

Loading...