Chapter 2 Profire V Burner

2-44 750-177

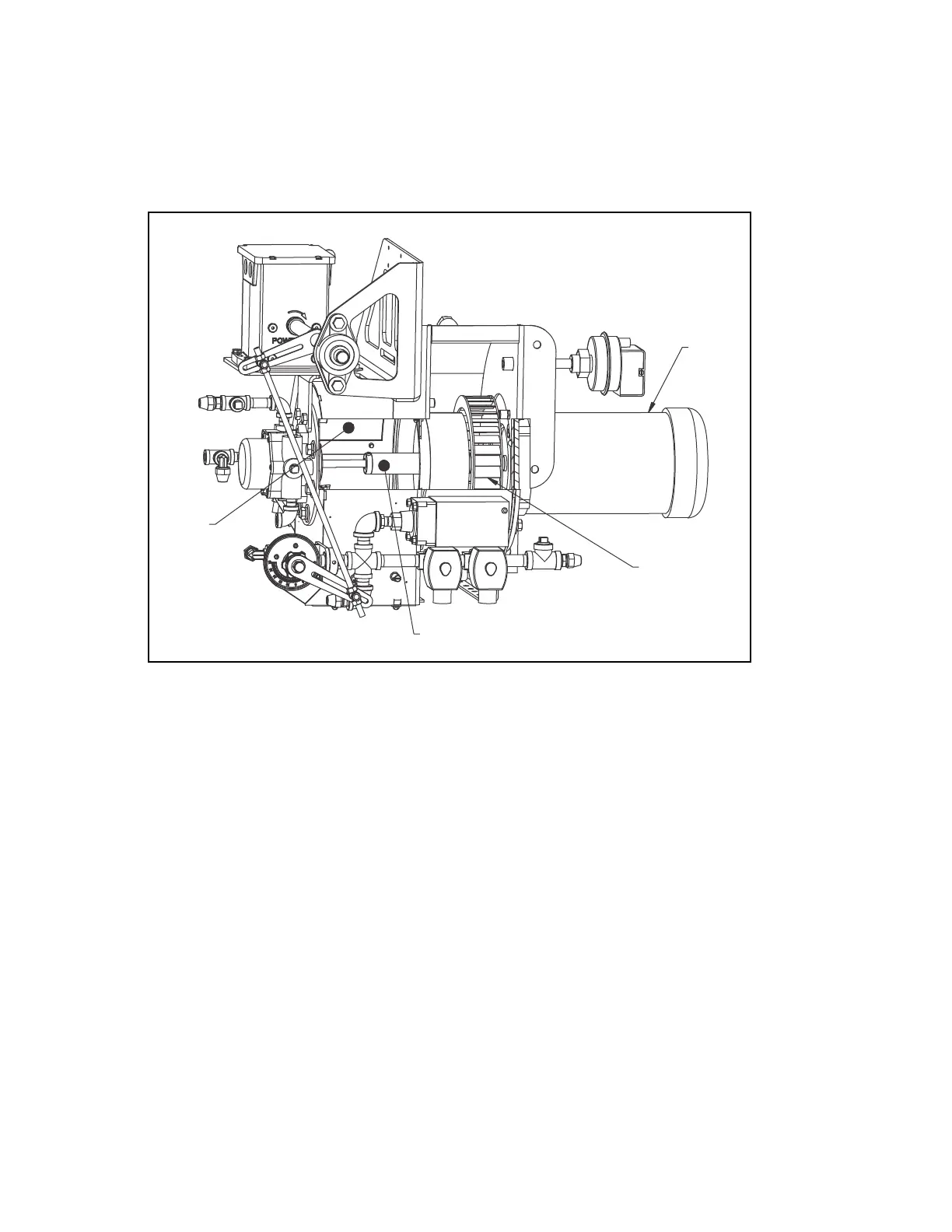

AIR HANDLING SYSTEM

A balanced blower wheel requires minimal maintenance. Check

for dirt buildup and clean the blades as

required. Inspect the impeller hub and blades for cracks. Replace if any are noticed. Make sure the air inlet

cone fits inside the impeller.

BLOWER

MOTOR

IMPELLER

WHEEL

FLEXIBLE

COUPLING

ACCESS

COVER

656-10212-000

Figure 2-28: Air Handling System

IMPELLER AND INLET CONE

Proper clearance between the impeller and the inlet housing set at 3/8” nominal. Adjust the

inlet cone so itis

centered in the inlet of the impeller and tighten the bolts. There should be no contact between the inlet cone

and the impeller. Inserting a bar through the impeller blade and using it as a lever will only damage the blade.

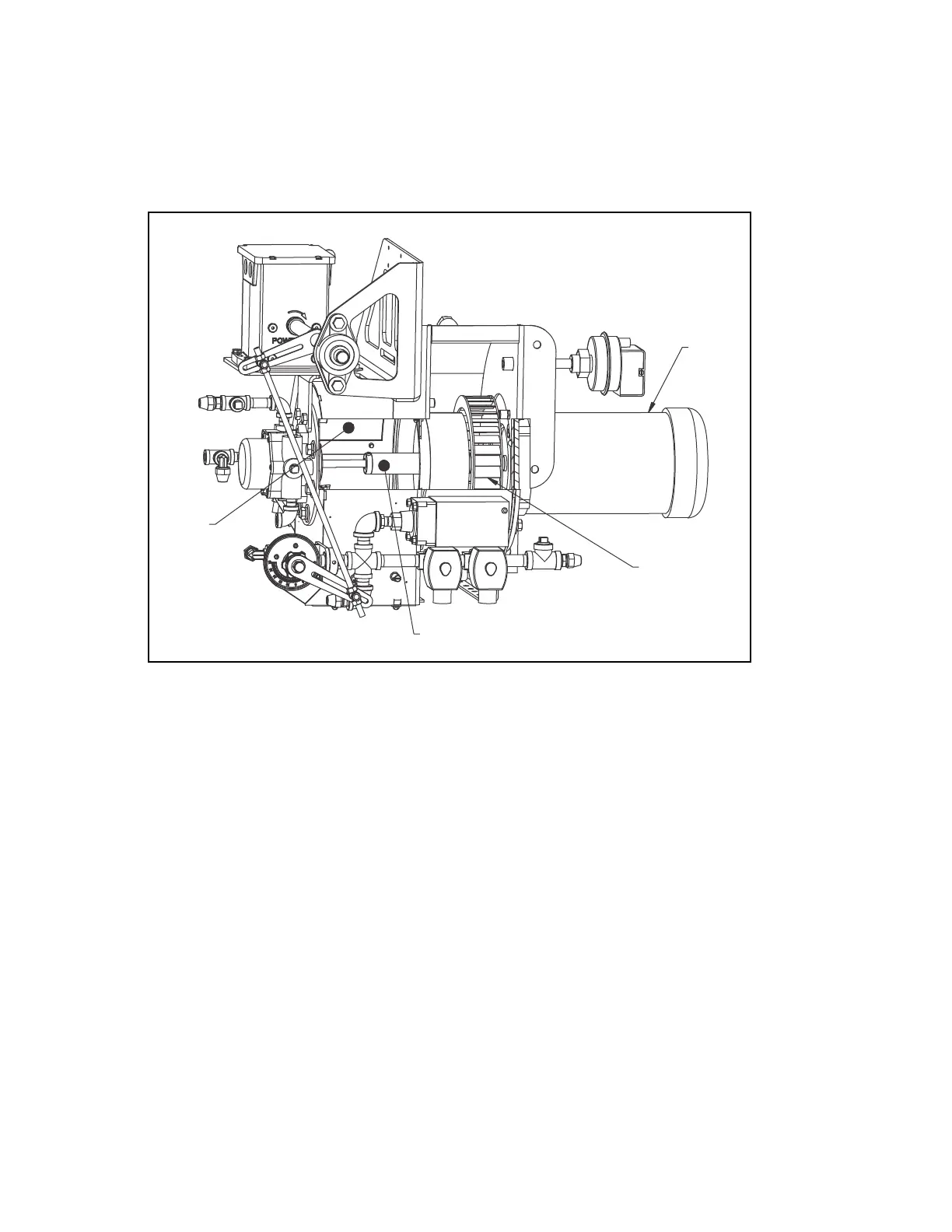

FIRING HEAD INSPECTION

Open side access panels to view the drawer

assembly. Inspect the lead wire to the ignition electrode. It must

be firmly attached and the insulation should be clean and free of cracks. The oil nozzle should be inspected

periodically.

If fibrous material is discovered in the gas spud ports, remove the

gas spud and back flush with shop air.

Further inspection of gas piping and gasket connections must be made to isolate the contaminate source. Be

sure to orientate the gas spuds in the correct position when reassembling the gas spuds.

The drawer assembly may be removed for

inspection and/or service. For drawer assembly drawings, refer to

Figures 2-15 to 2-24.

1. Shut off the burner; position the switch to “Off”.

2. Shut off all electric power to the burner.

3. Disconnect the fuel lines from the drawer assembly access cover.

Loading...

Loading...