38 CSRN-XHE2 FFA 12.2-24.4 M07Z40M15-02

10.3 Immersed electrode humidier

SUPPLY WATER

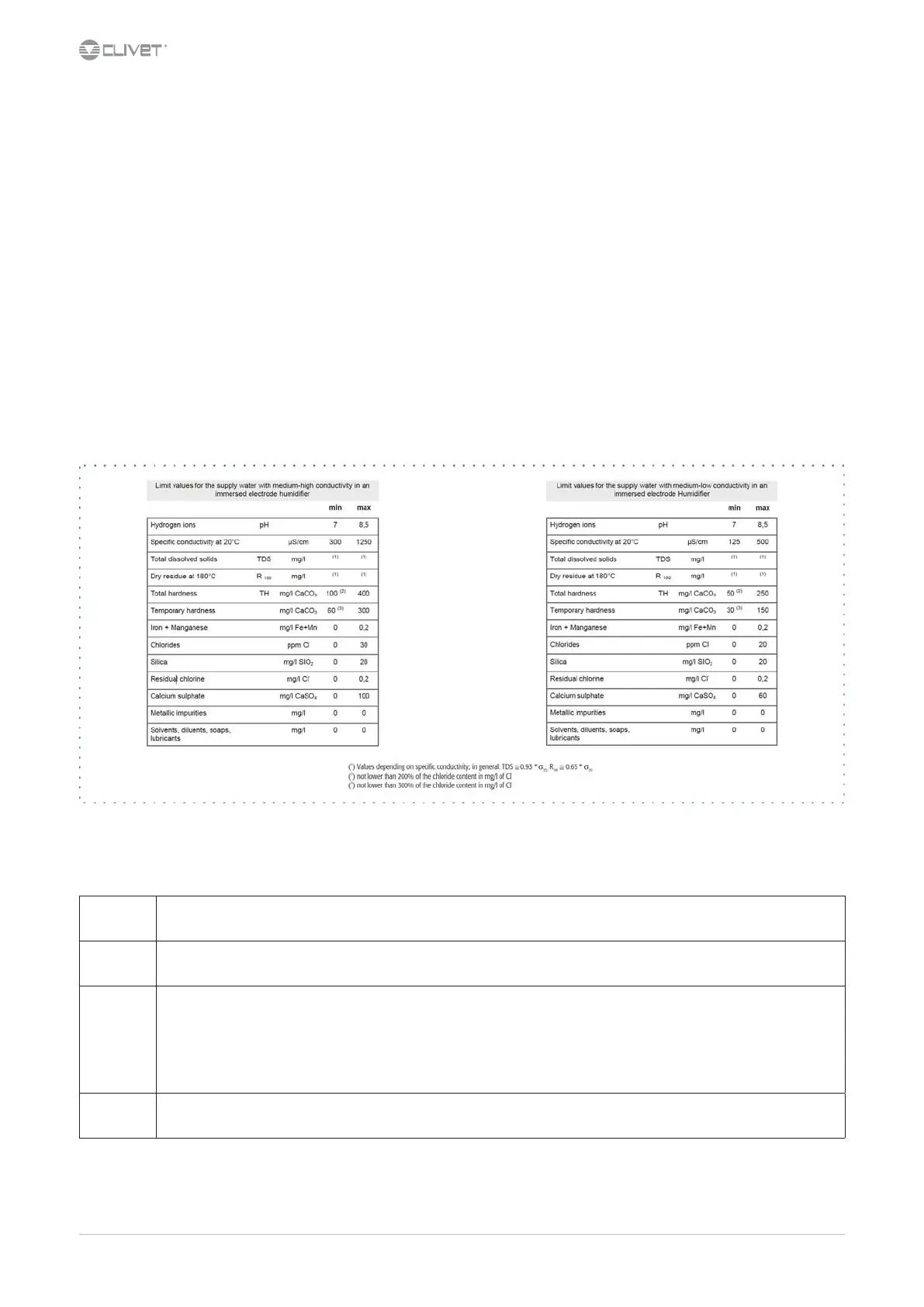

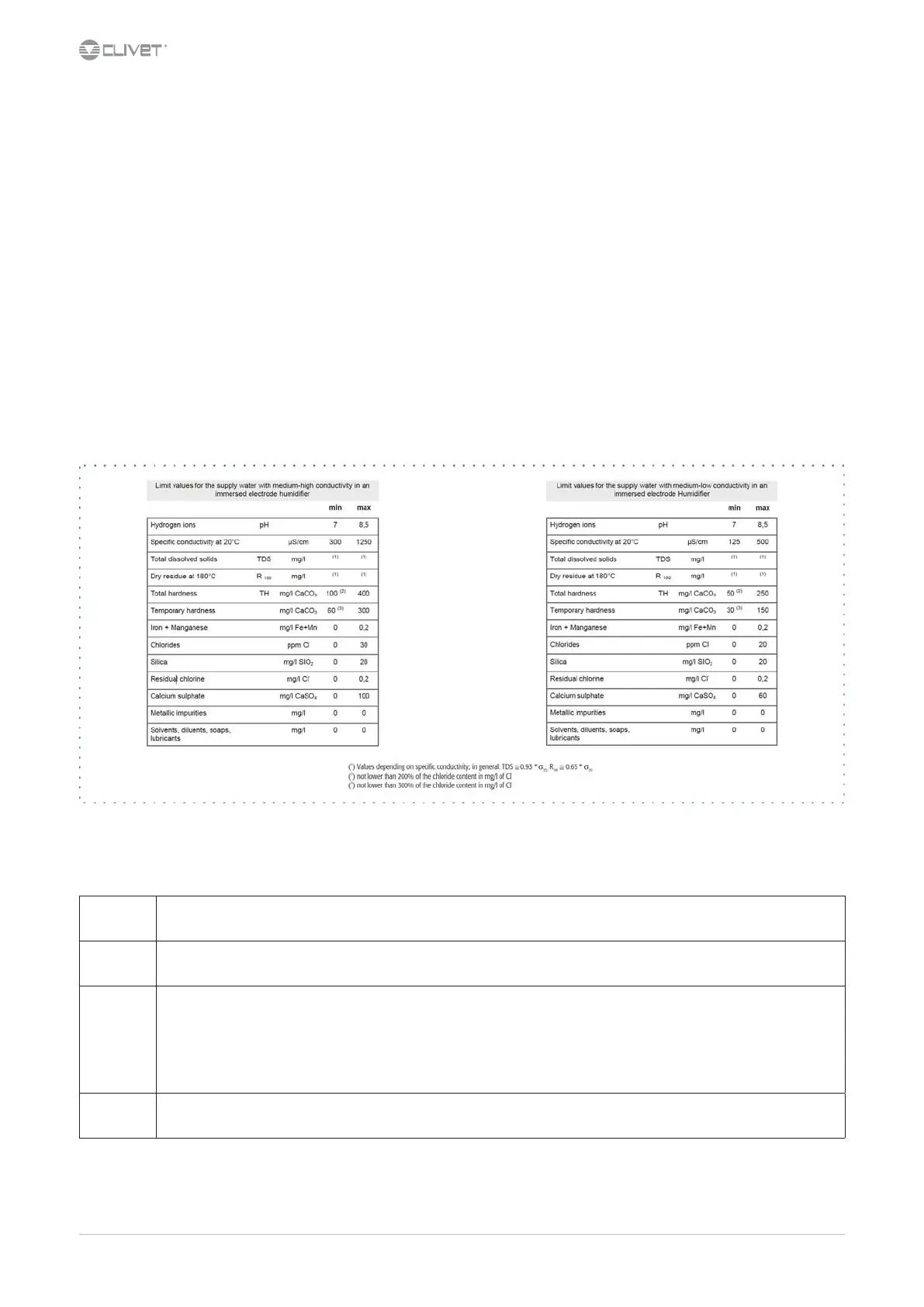

The humidier must be supplied with mains water having the following features:

•

pressure between 0.1 and 0.8 Mpa (1 – 8 bar)

•

temperature between 1 and 40°C

Do not use:

•

water treated with softeners: it can corrode the electrodes and form foam with possible faults/malfunctionings

•

pit, industrial or potentially polluted (chemically or bacteriologically) water

•

disinfectants or anti-corrosive substances mixed with water, as potentially irritating

Supplying the humidier with water treated with reverse osmosis ltering system gives the following advantages:

•

reduces limescale deposits

•

reduces energy consumptions

•

reduces maintenance costs

•

increases humidier duration

Check that the lter guarantees a water ow rate higher than the ow rate of the installed humidier.

DRAINAGE WATER

It can reach a temperature of 100°C

It contains the same substances of the supply water but in higher concentration.

As it is not toxic, it can be disposed of with white waters.

Periodical checks

Do not use solvents or detergents to clean the plastic components.

For descaling use a vinegar or acetic acid solution at 20%, subsequently rinsing with water.

15 days

Cylinder:

not over 300 hours of work

checking operation, general state, no leaks

90 days

Cylinder:

not over 1000 hours of work

checking operation, general state, no leaks, any replacement

1 year

Cylinder:

not over 2500 hours of work (disposable cylinders)

Load solenoid valve replacement:

disconnect electric power supply, dismantle valve, clean the lter

Drain solenoid valve:

disconnect electric power supply, remove reel and dismantle valve body and any impurity and rinse

The power supply bowl, piping:

check they are free and without impurities

5 years

Cylinder:

not over 10000 hours of work (inspectional cylinders)

replacement

Loading...

Loading...