8

◆

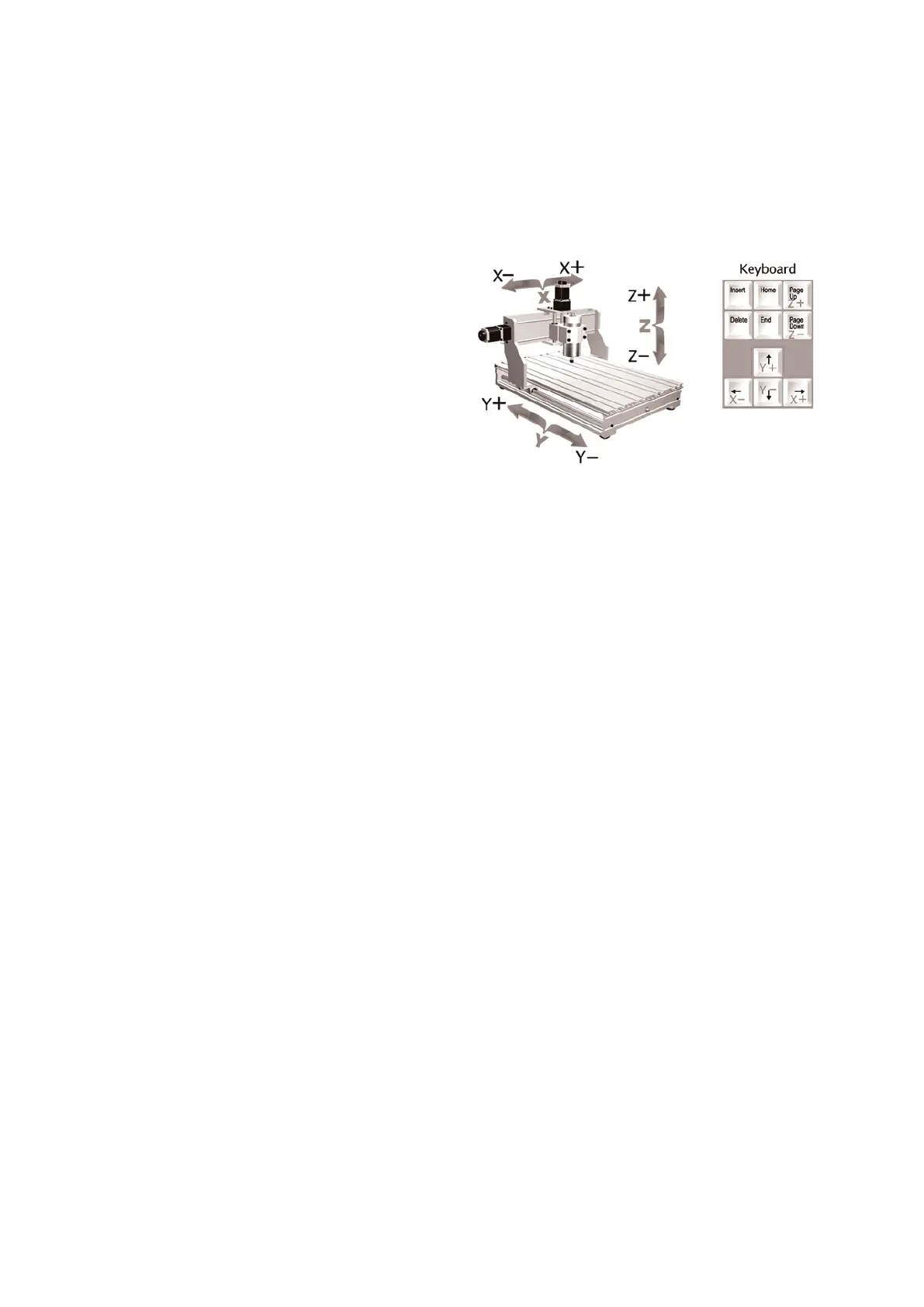

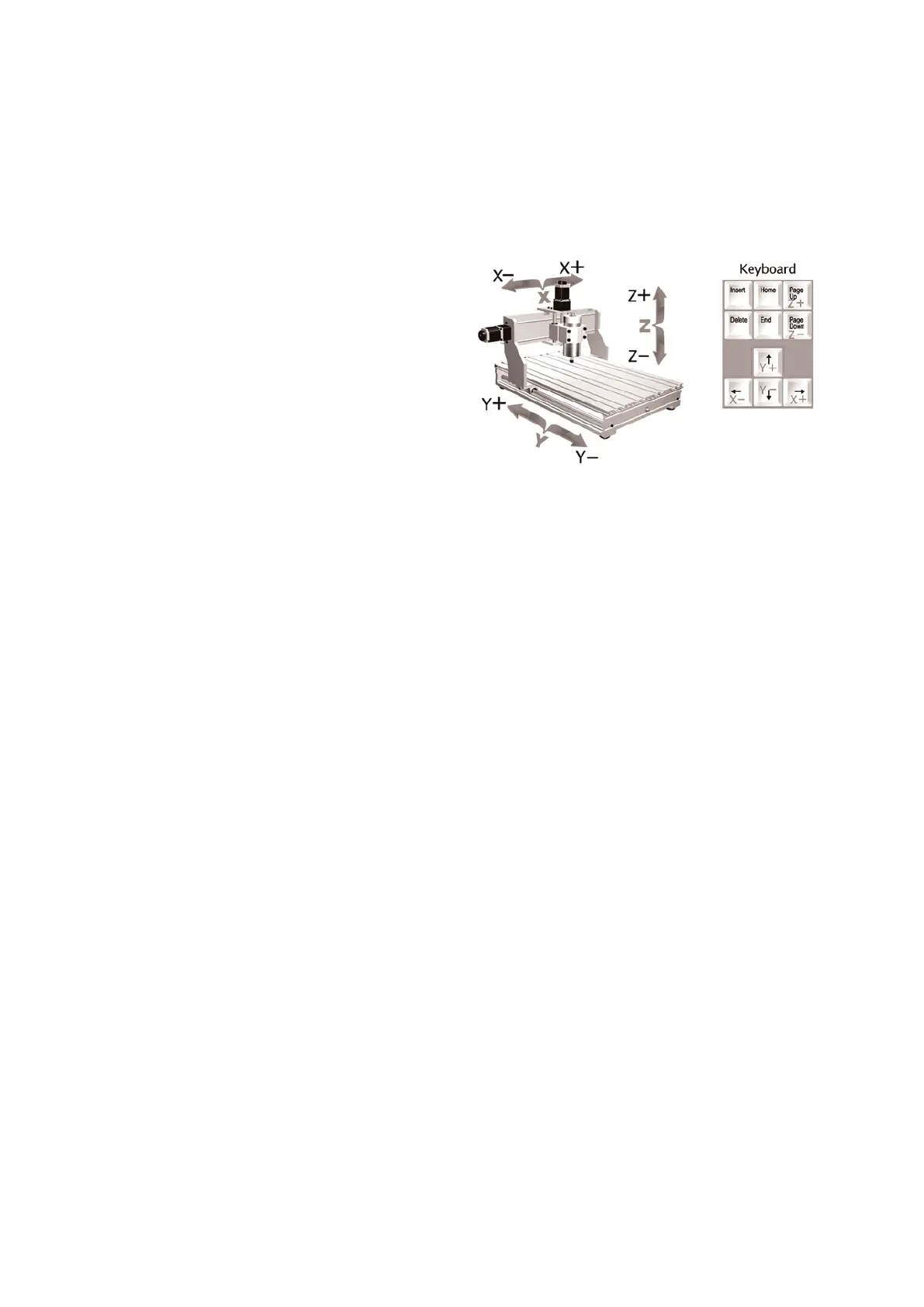

Definition of triaxial coordinate

The following is the reference drawing of the triaxial coordinate definition provided by us. During the

process of trial run, if we found the running direction of the axis is incorrect, we can change the "Dir

LowActive" in the "Motor Outputs" of MACH3 to adjust it.

This coordinate definition is just a usual definition

mode of us, which is for reference only; in practice,

you can change the definition in accordance with

your habit and the specific situation of design

software.

Till now, the communication test of engraving

machine and control software is finished. If your

engraving machine still cannot be controlled regularly, please solve this problem by the following

methods:

① Uninstall MACH3 software, change the MACH3 of other version, and do installation test (because

some main board parallel ports are not compatible with MACH);

② Check whether your parallel port is normal, and please change another set of qualified desktop

computer and do test.

③ After install MACH3, if you have opened the software without rebooting the computer first , you must

completely uninstall the software and reinstall it.

④ If three step motors cannot self-locking after the control box is electrified, please contact with your

dealer in time.

---------------------------------------------------------------------------------------------------------------------------------------

◆

Test for "water cooling spindle motor"

Please confirm that you have connected the water pump, water pipe, and water tank in accordance

with requirements before test.

1. After turning on the POWER switch and the PUMP switch, water pump may begin to work regularly,

and the cooling water begins to circulate;

2. Turn on the VFD switch, and start VFD about three seconds later, then "000" may be showed on the

LED; Slowly turn the speed control knob to the maximum in clockwise direction, and the digital display

should be 400H z at last; If not, please stop operating and turn off the power, and then contact with your

dealer. If it is displayed normally, please slowly turn the speed control knob in anticlockwise direction,

and stop when the LED display is 150 Hz . Then, press the "RUN" key on the control panel, and now the

spindle motor should begin to rotate quickly. Slowly adjust the rotation speed, and it may be the

maximal rotation speed (about 24000 r/min ) when the LED display is 400 Hz . 1H z equals about 60 r .

Loading...

Loading...