Section 3 Installation

3-6

Cole Palmer

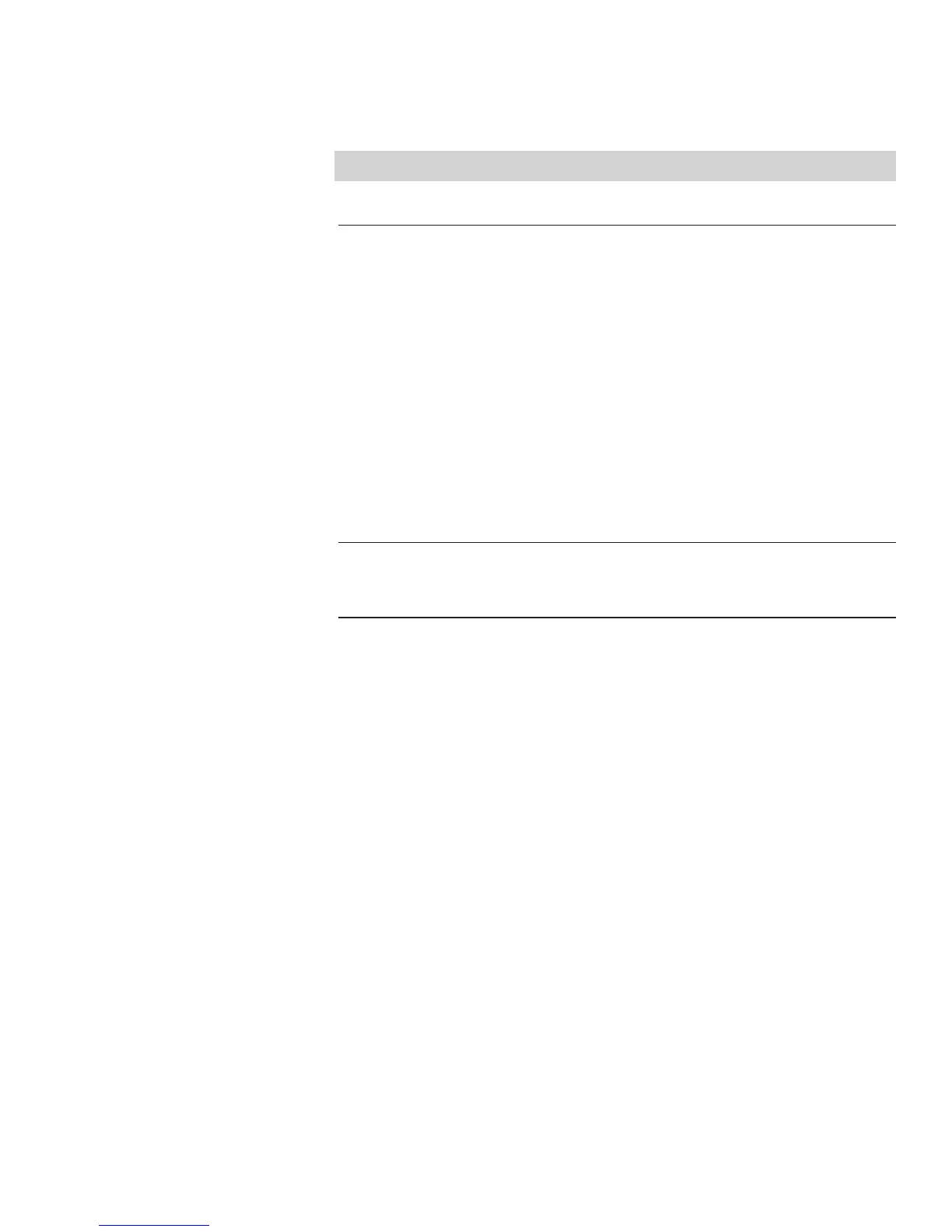

Process Fluid Permissible (PPM) Desirable (PPM)

Microbiologicals

(algae, bacteria, fungi) 0 0

Inorganic Chemicals

Calcium <25 <0.6

Chloride <25 <10

Copper <1.3 <1.0

0.020 ppm if fluid in contact with aluminum

Iron <0.3 <0.1

Lead <0.015 0

Magnesium <12 <0.1

Manganese <0.05 <0.03

Nitrates\Nitrites <10 as N 0

Potassium <20 <0.3

Silicate <25 <1.0

Sodium <20 <0.3

Sulfate <25 <1

Hardness <17 <0.05

Total Dissolved Solids <50 <10

Other Parameters

pH 6.5-8.5 7-8

Resistivity 0.01* 0.05-0.1*

* MΩ-cm (compensated to 25°C)

Unfavorably high total ionized solids (TIS) can accelerate the rate of galvanic

corrosion. These contaminants can function as electrolytes which increase

the potential for galvanic cell corrosion and lead to localized corrosion such

as pitting. Eventually, the pitting will become so extensive that refrigerant will

leak into the water reservoir.

As an example, raw water in the United States averages 171 ppm (of NaCl).

The recommended level for use in a water system is between 0.5 to 5.0 ppm

(of NaCl).

Recommendation: Initially ll the tank with distilled or deionized water. Do

not use untreated tap water as the total ionized solids level may be too high.

This will reduce the electrolytic potential of the water and prevent or reduce

the galvanic corrosion observed.

Water Quality and Standards

Loading...

Loading...