Identify and eliminate faults

A190-930TX_EN_03_ 2009-02-06 55

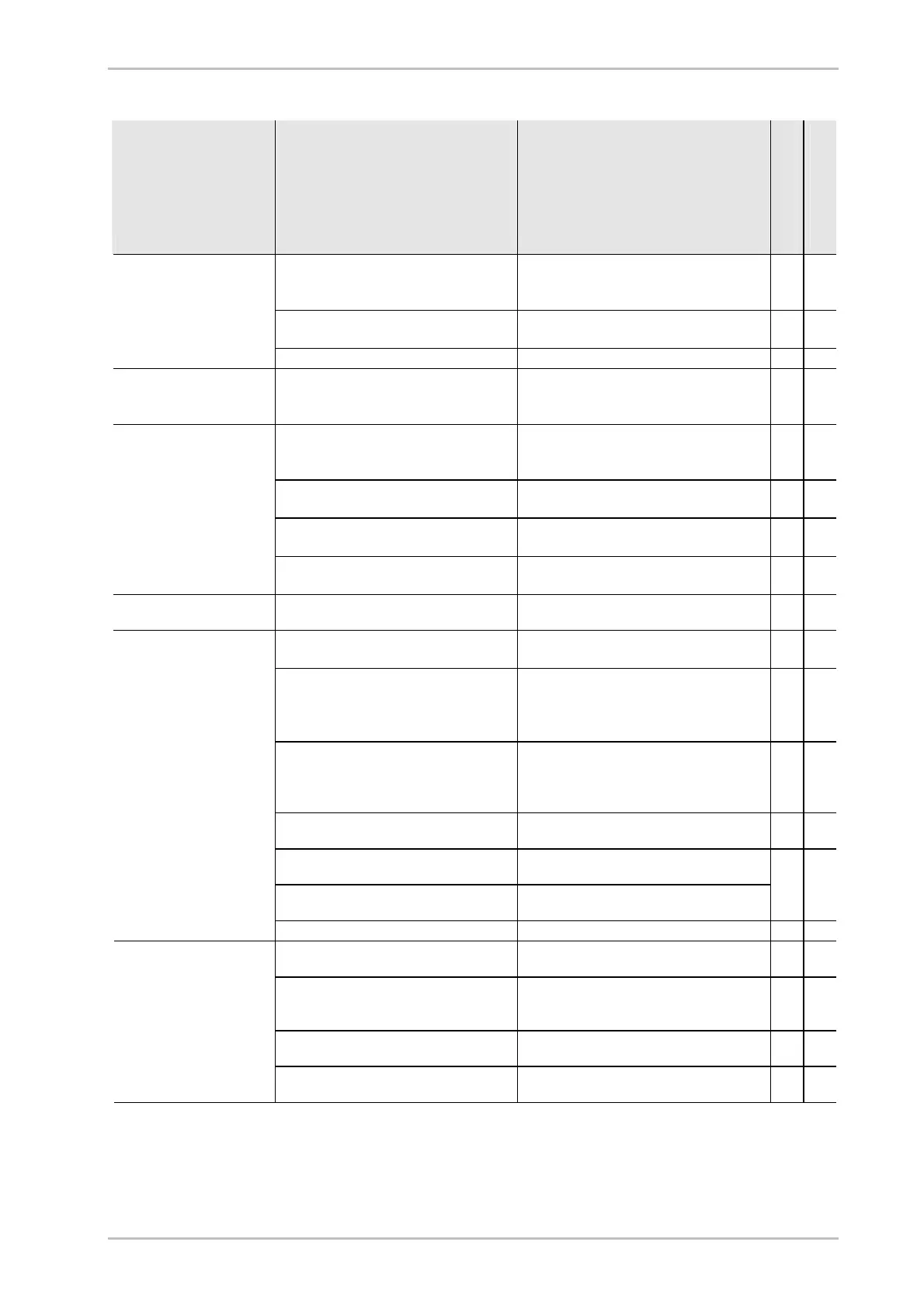

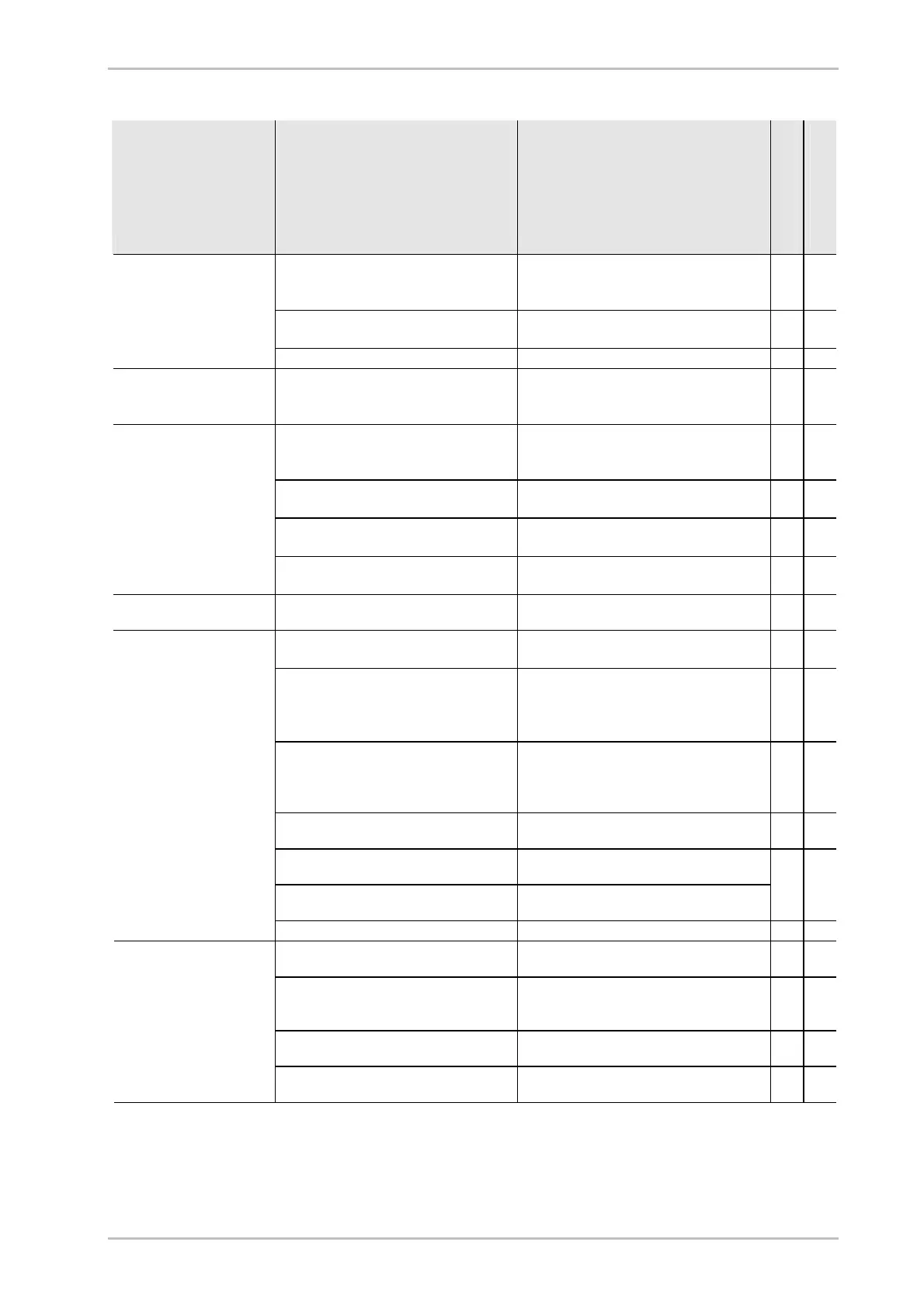

Table of possible faults

Fault Possible cause Remedy

Spec. personnel

Service engineer

Muffler or filter element of the muffler

is contaminated.

Check mufflers or filter elements for

contamination, clean if nec., and poss.

renew.

Expansion valve V4/V5 does not open

correctly.

Check expansion valve for

contamination, if nec. renew gaskets.

Excessive dam pressure

during regeneration

Dust sieves are contaminated. Clean or renew dust sieves.

Vessel pressure is too

low

Excessive differential pressure on the

upstream filter (option).

Check differential pressure on the

upstream filter, if. nec. renew filter

element.

The compressed air system upstream

of the dryer is not pressurised.

Check whether the compressed air

system upstream of the dryer is

pressurised. Remove any faults.

Check valve V2/V3 is leaky. Check check valve, if nec. renew

gasket.

Solenoid valve Y3/Y4 does not close. Check supply voltage, cable, contacts

and solenoid; replace, if necessary.

No pressure build up

Expansion valve V4/V5 does not

close.

Check gaskets for contamination, if nec.

clean/renew.

Excessive compressed

air consumption

Leakage. Check condensate trap at the upstream

filter (option); clean, if necessary.

Solenoid valve Y1/Y2 does not open. Check supply voltage, cable, contacts

and solenoid; replace, if necessary.

Main inlet valve V1 does not switch

correctly.

Check operating pressure of control air;

if nec. restore. Otherwise check

function/easy switching of main inlet

valve, if nec. renew.

Solenoid valve Y1/Y2 cannot be

opened properly

(audible humming sound or valve

flapping).

Check supply voltage.

Check solenoid valves; replace, if

necessary.

Control board defective. Check fuse in supply line and in the

switchbox; replace, if necessary.

Power supply interrupted, cable

broken.

Reconnect the unit to the power supply.

Compressor might be off. Check compressor synchronisation

circuit.

Dryer does not switch

over

Error in control programme. Restart programme.

Solenoid valve Y3/Y4 cannot be

opened.

Check supply voltage, cable, contacts

and solenoid; replace, if necessary.

Solenoid valve Y3/Y4 cannot be

opened properly (audible humming

sound or valve flapping).

Check supply voltage.

Check solenoid valves; replace, if

necessary.

Expansion valve V4/V5 does not open

correctly.

Check gaskets for contamination, if nec.

clean/renew.

No expansion

Muffler blocked. Check muffler for contamination, if nec.

clean/renew.

Loading...

Loading...