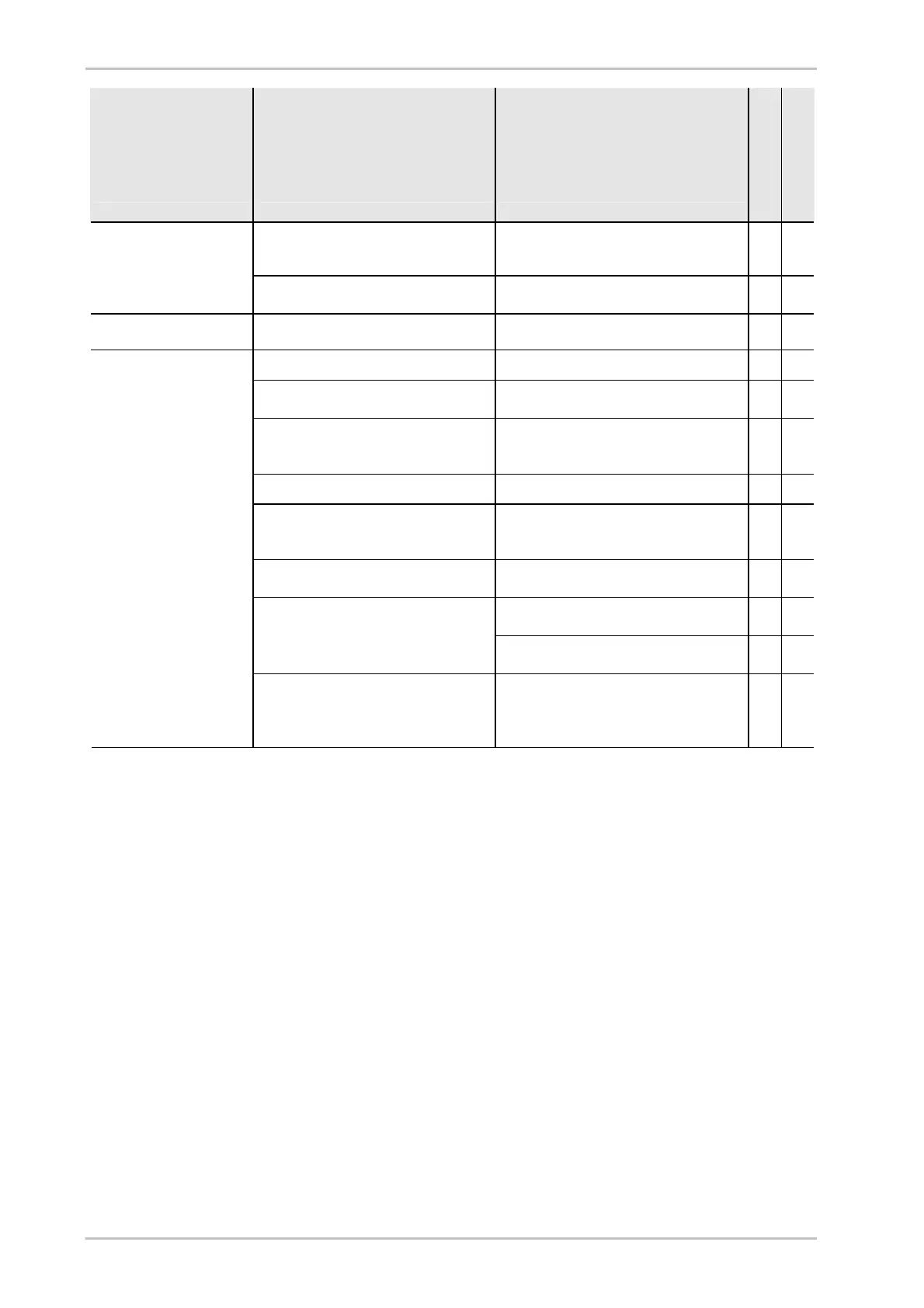

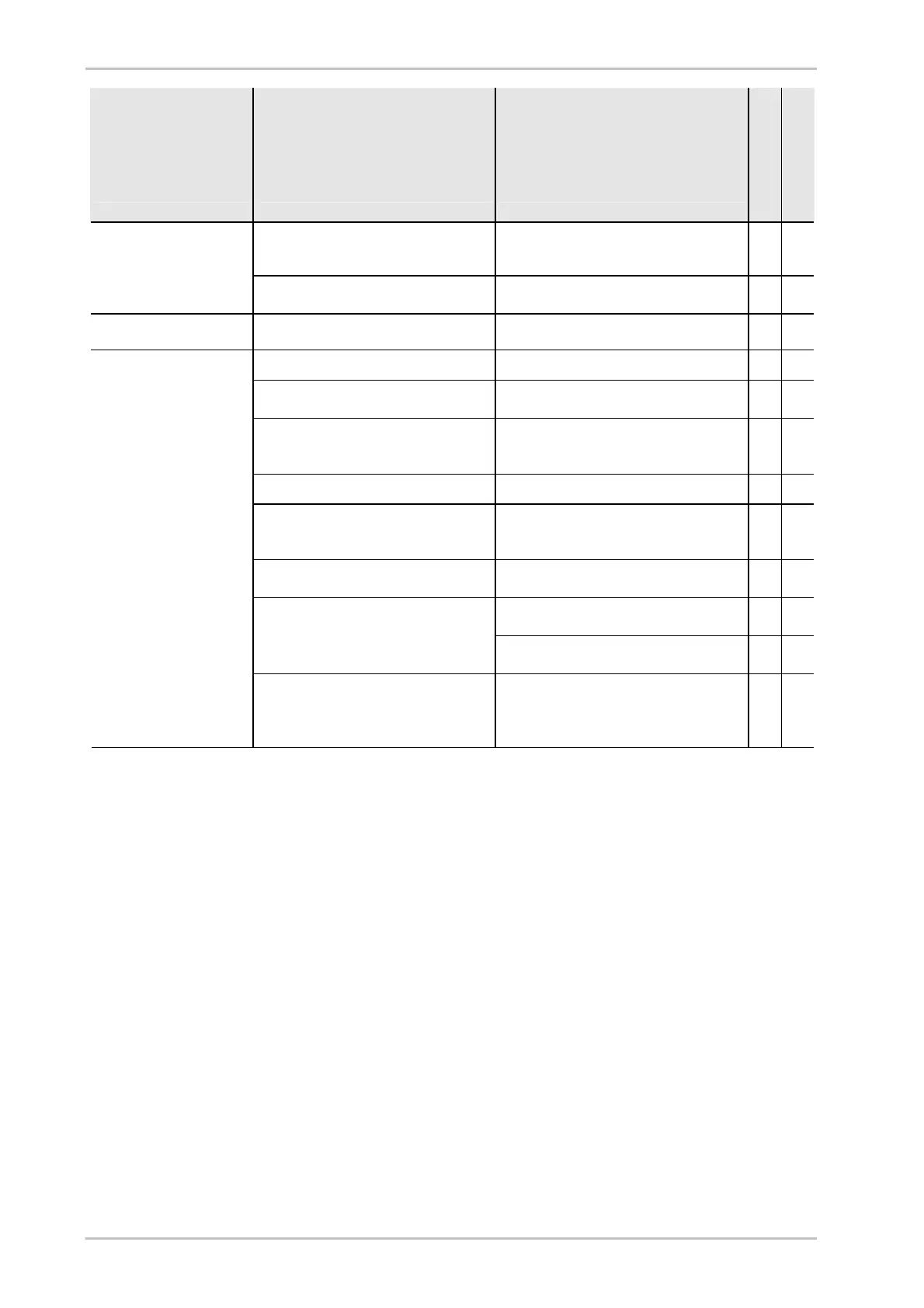

Summary of faults

56 A190-930TX_EN_03_ 2009-02-06

Fault Possible cause Remedy

Spec. personnel

Service engineer

Solenoid valve Y3/Y4 cannot be

closed properly (audible humming

sound or valve flapping).

Check supply voltage.

Check solenoid valve; replace, if

necessary.

Dryer is continuously

bled

Expansion valve V4/V5 does not close

correctly.

Check gaskets for contamination, if nec.

clean/renew.

Dryer is excessively bled Solenoid valve Y1/Y2 cannot be

closed.

Check solenoid valves; replace, if

necessary.

Operating pressure is too low. Increase operating pressure.

Compressed air volume flow is too

high.

Reduce compressed air volume flow

Compressed air inlet temperature is

too high.

Reduce compressed air inlet

temperature or pre-connect a

compressed air cooler.

Control board is defective. Check control board, if nec. renew.

Differential pressure on the upstream

filter (option) is too high.

Check differential pressure on the

upstream filter, if nec. renew filter

element.

Condensate trap on the upstream

filter (option) does not work.

Check function of the condensate trap,

if nec. clean or renew.

Check upstream filter for contamination,

if nec. renew element.

Drying agent is contaminated or too

old.

Check drying agent for contamination, if

nec. renew drying agent.

Pressure dew point is not

reached

Regeneration gas too low. Check function of expansion valve

V3/V4 and muffler, if nec. renew muffler

or filter element.

Loading...

Loading...