29

CONTROLS

Adjustment to all controls are made very

carefully at the factory. However, it may be

necessary to make certain adjustments at

the time the unit is installed, to fit specific

applications, or after repair or replacement of

components.

The control pressure regulator valve (CPR) is

the only control device which may require

adjustment.

CAUTION

DO NOT EXCEED THE RATED MAXIMUM

FULLY LOAD OPERATING PRESSURE OF

ANY UNIT. REFER TO “SPECIFICATIONS”,

SECTION II.

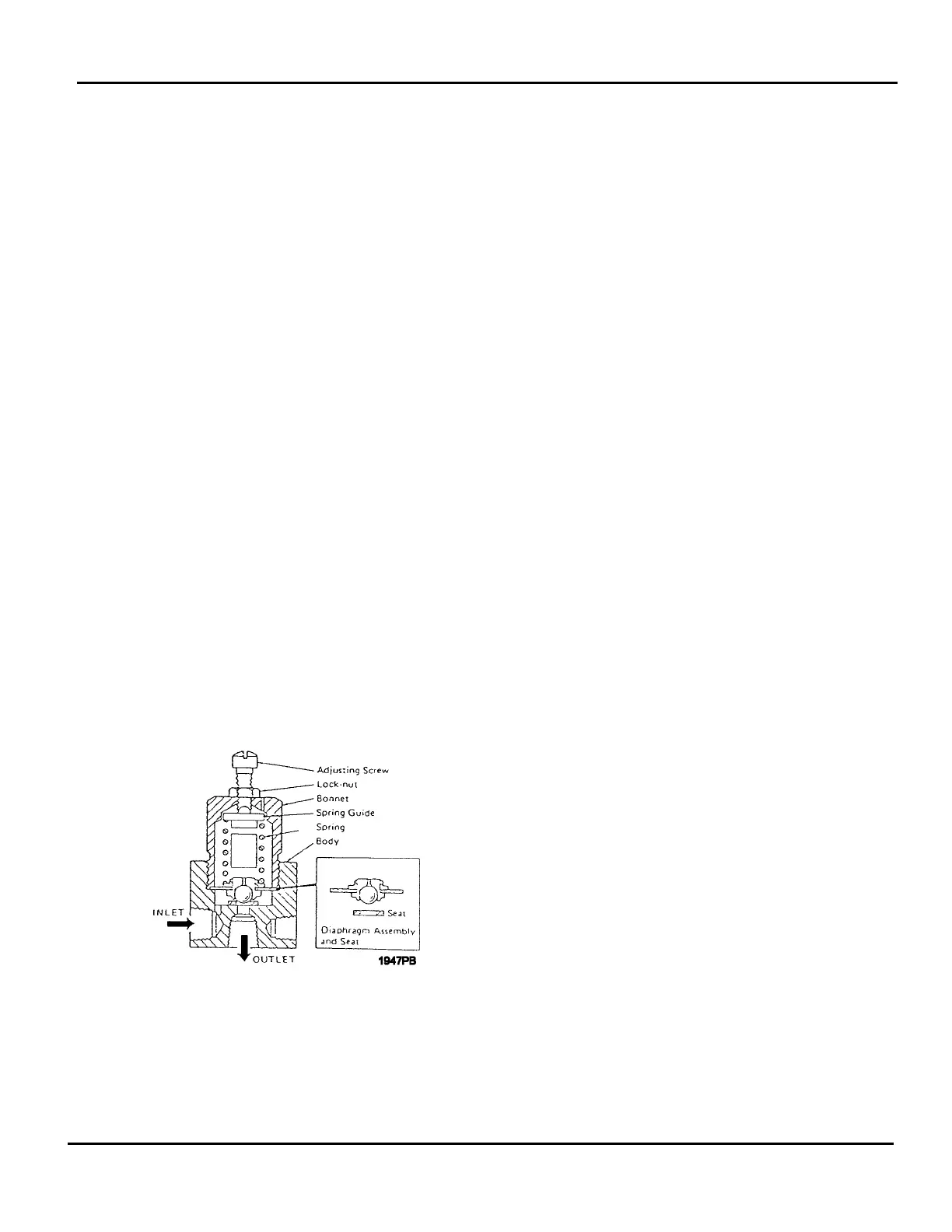

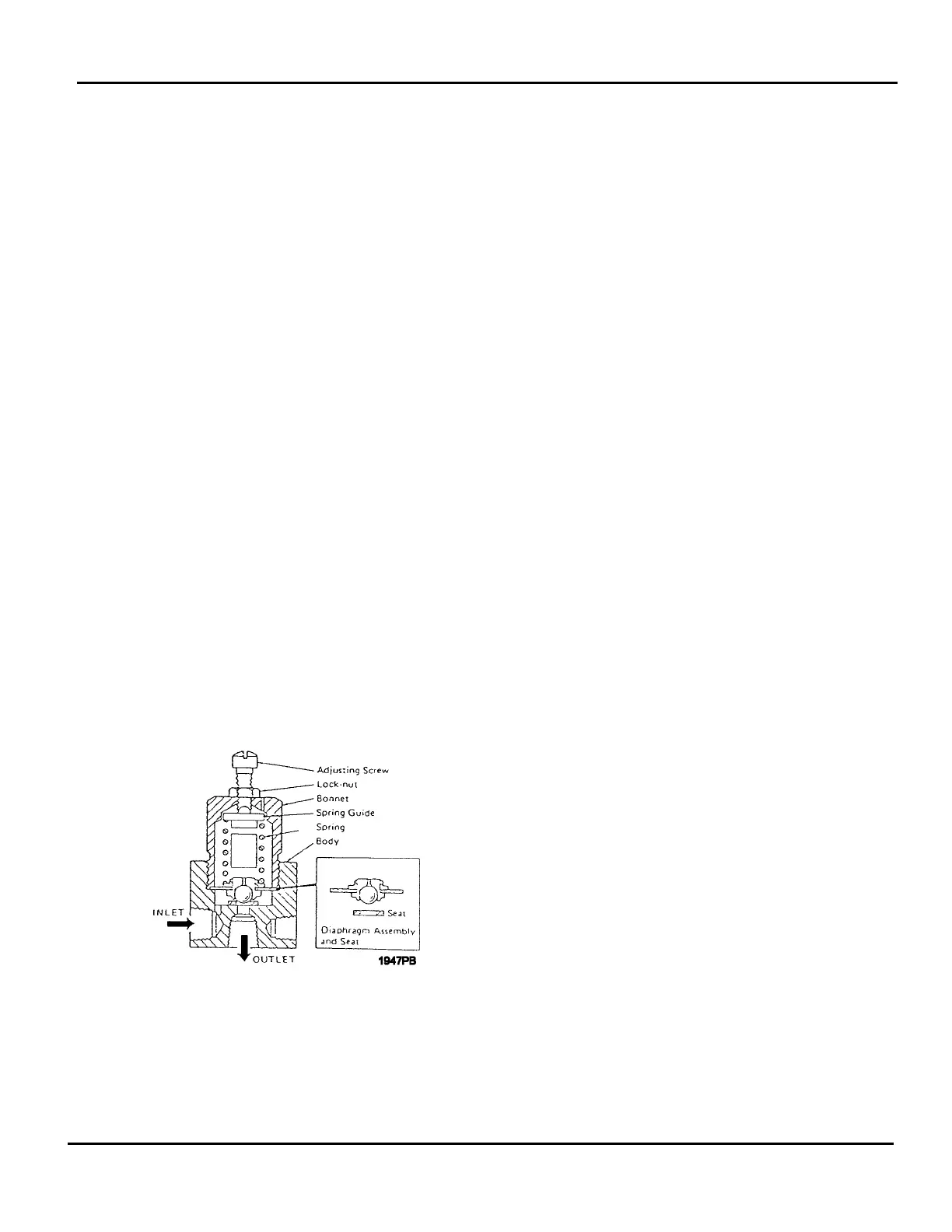

MODULATING CONTROL - CONTROL

PRESSURE REGULATOR (CPR) VALVE

ADJUSTMENT (Figure 11)

To change the pressure at which the CPR

(control pressure regulator) valve will fully

unload the compressor, loosen the adjusting

screw locknut and turn the adjusting screw in

(clockwise) to increase of out

(counterclockwise) to decrease pressure.

Tighten the locknut securely when finished.

FIGURE 11 - CONTROL PRESSURE

REGULATOR VALVE

Follow this procedure:

1. Install/connect pressure test gages

(minimum pressure range 200 psi), if

required, in place of the existing air

pressure gages.

2. Connect a pressure test gage with a

minimum range of 100 psi in the control

pressure line near the air intake valve.

WARNING

AIR ESCAPING TO ATMOSPHERE IS

NOISY. WEAR EAR PROTECTION TO

PROTECT HEARING AGAINST HIGH

INTENSITY NOISE.

3. Open the drop leg or receiver vent valve.

Start the unit. Slowly close the drop leg

or vent valve to raise both the unit and

system receiver air pressure to 80 psi,

approximately. Allow the unit to run long

enough to reach normal operating

temperature.

4. Adjust the service (drop leg or vent)

valve to maintain a constant rated full

load pressure. (i.e. 100, 125 or 150 psi).

CAUTION

CHECK SECTION II OF THIS MANUAL TO

OBTAIN INFORMATION ABOUT

MAXIMUM OPERATING PRESSURE AND

AIR END SPEED.

5. Observe the pressure test gage

connected in the control pressure line.

Loosen the adjusting screw locknut and

adjust the control pressure regulator

(CPR) valve by turning the adjusting

screw out (counterclockwise) until a

pressure of 3 to 5 psi is observed on the

control line test gage.

6. Then turn the CPR valve adjusting

screw in (clockwise) far enough to obtain

a control pressure of zero. (No control

air bleed). Securely tighten adjusting

screw locknut.

7. Cycle the controls by adjusting the

service (drop leg or vent) valve to raise

the lower both unit and system receiver

air pressure.

SECTION VI

CONTROLS AND ADJUSTMENT PROCEDURES

Loading...

Loading...