36

performance for specific combinations of

motor horsepower and system pressure

requirements. Initial belt tensioning will

rapidly drop off during the first fifty to one

hundred hours of compressor operation.

Therefore, belt tension should be monitored

daily during this period to minimize belt wear.

A belt that is too loose will slip, causing

excessive heat and accelerated wear. Belts

that are too tight will cause an overload

condition on motor and/or compressor

bearings.

BELT INSTALLATION AND ADJUSTMENT

When installing new belts, do not pry the

belts over the pulley grooves. The proper

installation method follows:

1. Disconnect and lock out all electrical

power to the compressor.

2. Remove the front panel to allow access

to the belt drive and remove the front

belt guard.

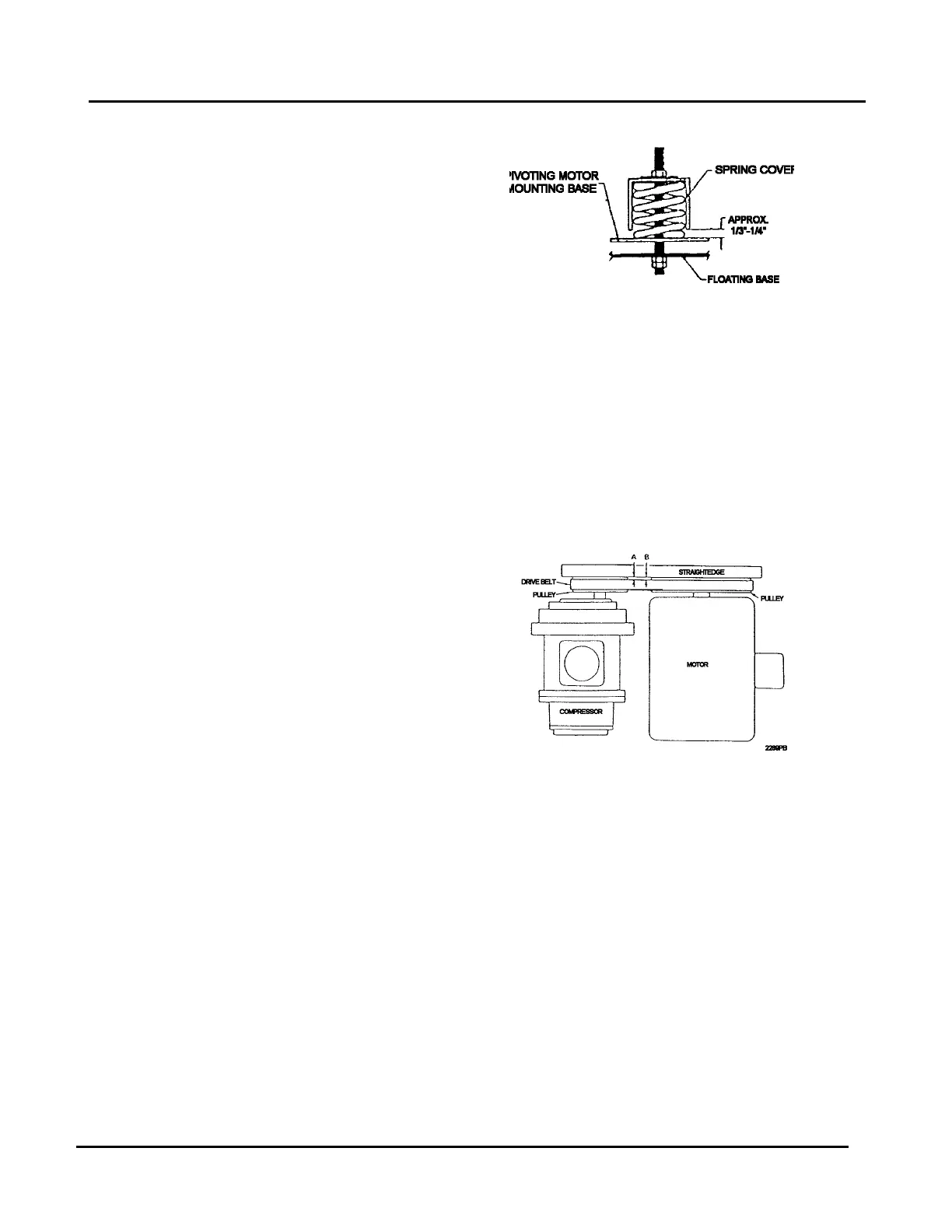

3. Loosen and remove the nut from the

threaded rod on the spring tensioning

belt adjustment device, located next to

airend on the airend mounting plate.

4. Push motor over toward the airend,

allowing the complete assembly to pivot

on the base. Remove the old belts.

5. Install new belts. Tilt motor assembly

back away from airend as far as

possible. Reinstall nut and washer on

threaded rod and tighten until the bottom

of the spring cover is within 1/8” - 1/4”

from the pivoting airend mounting base.

Check belt tension to make sure tension

is correct. Loosen or tighten nut to

compress spring as required.

6. Restore electrical power and restart the

compressor to check correct tracking of

the belts.

7. Replace the front belt guard and front

panel.

PULLEY ALIGNMENT

Realignment of pulleys is not required during

normal belt service, however, if pulleys, motor

or airend positions are changed realignment

of pulleys should be done by following

method.

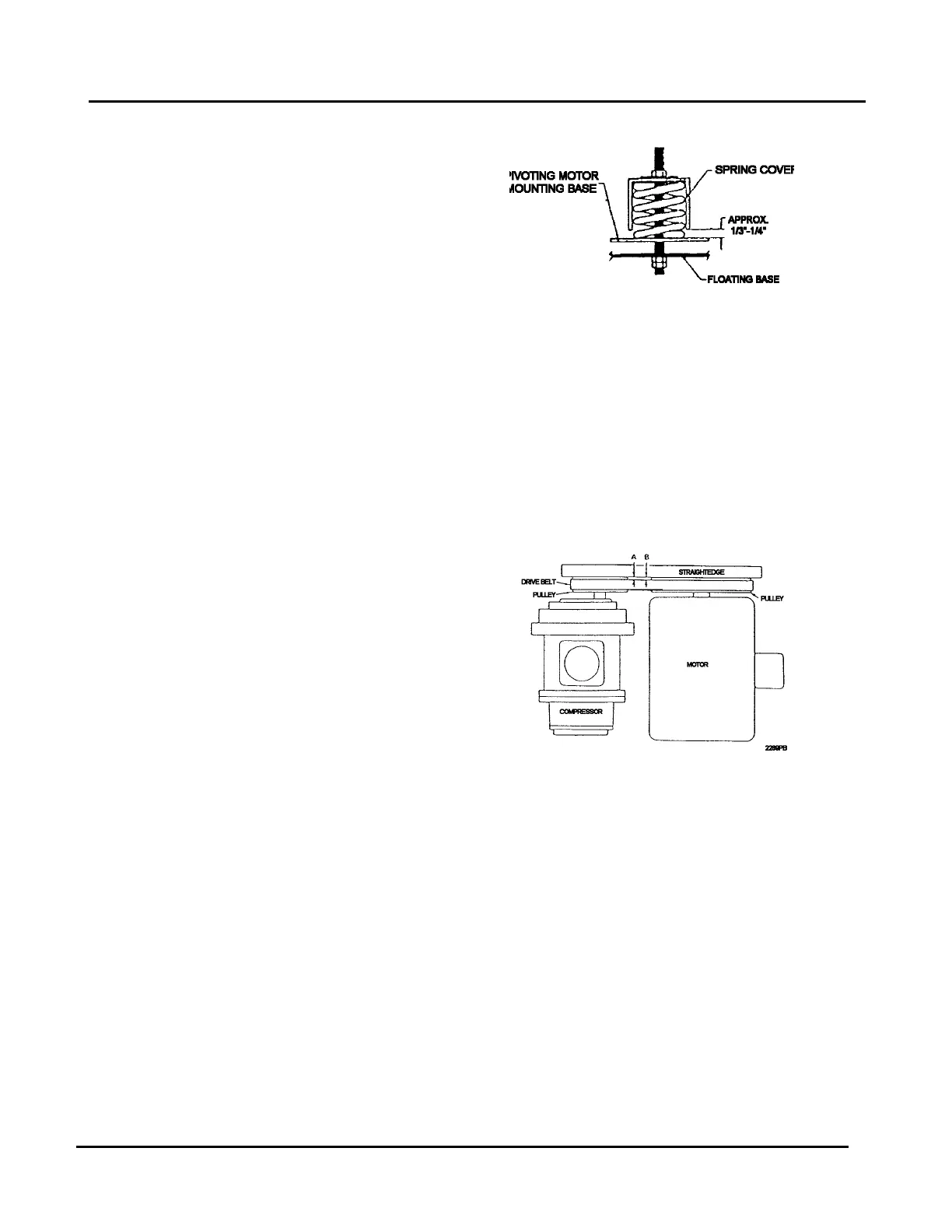

FIGURE 15

Check the pulley alignment by placing a

straight edge against the side of the drive

pulleys and measure to the edge of the belts

at points A and B. If these two

measurements are the same, the pulleys are

correctly aligned.

If these two measurements are not the same,

reposition the pulleys to obtain correct

alignment.

FIGURE 16

Loading...

Loading...