38

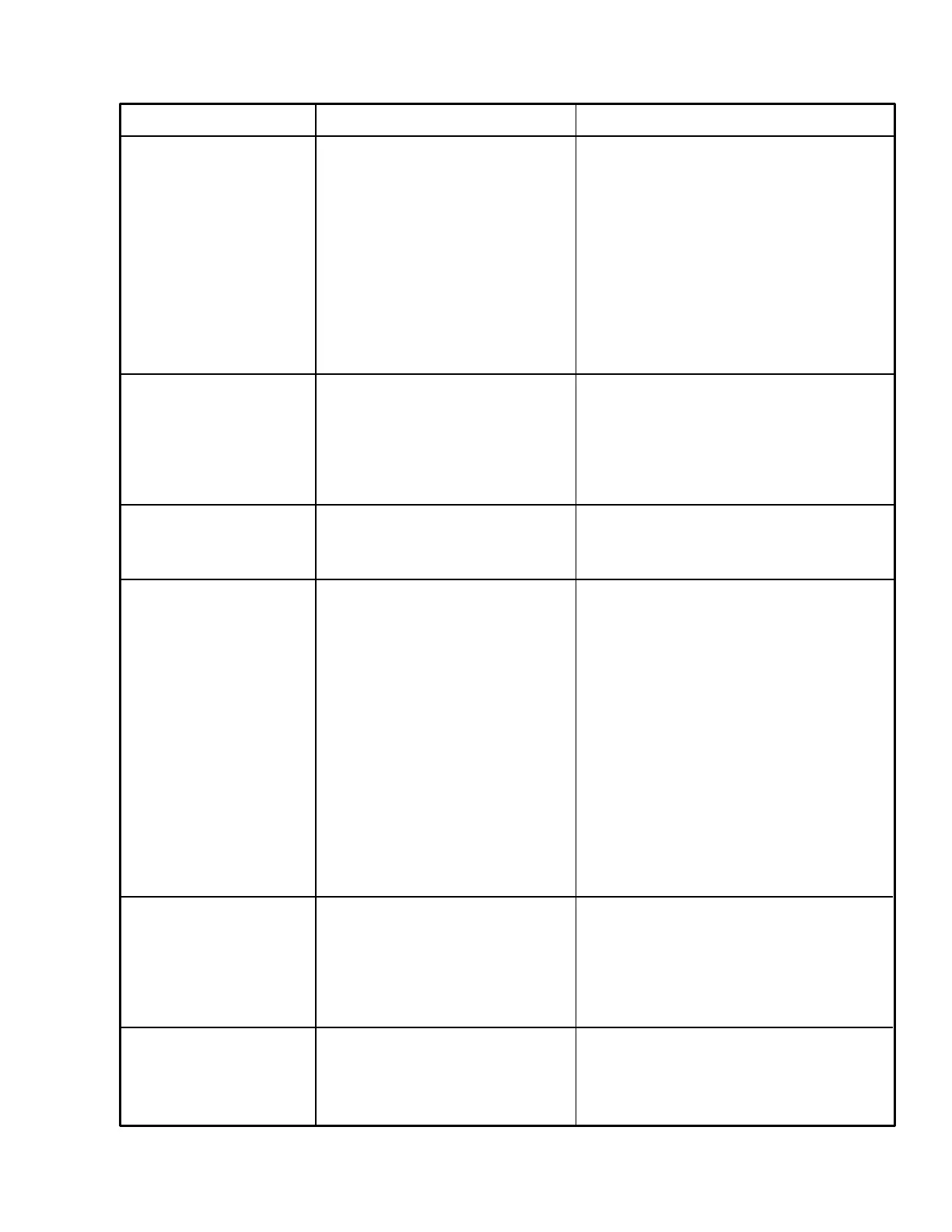

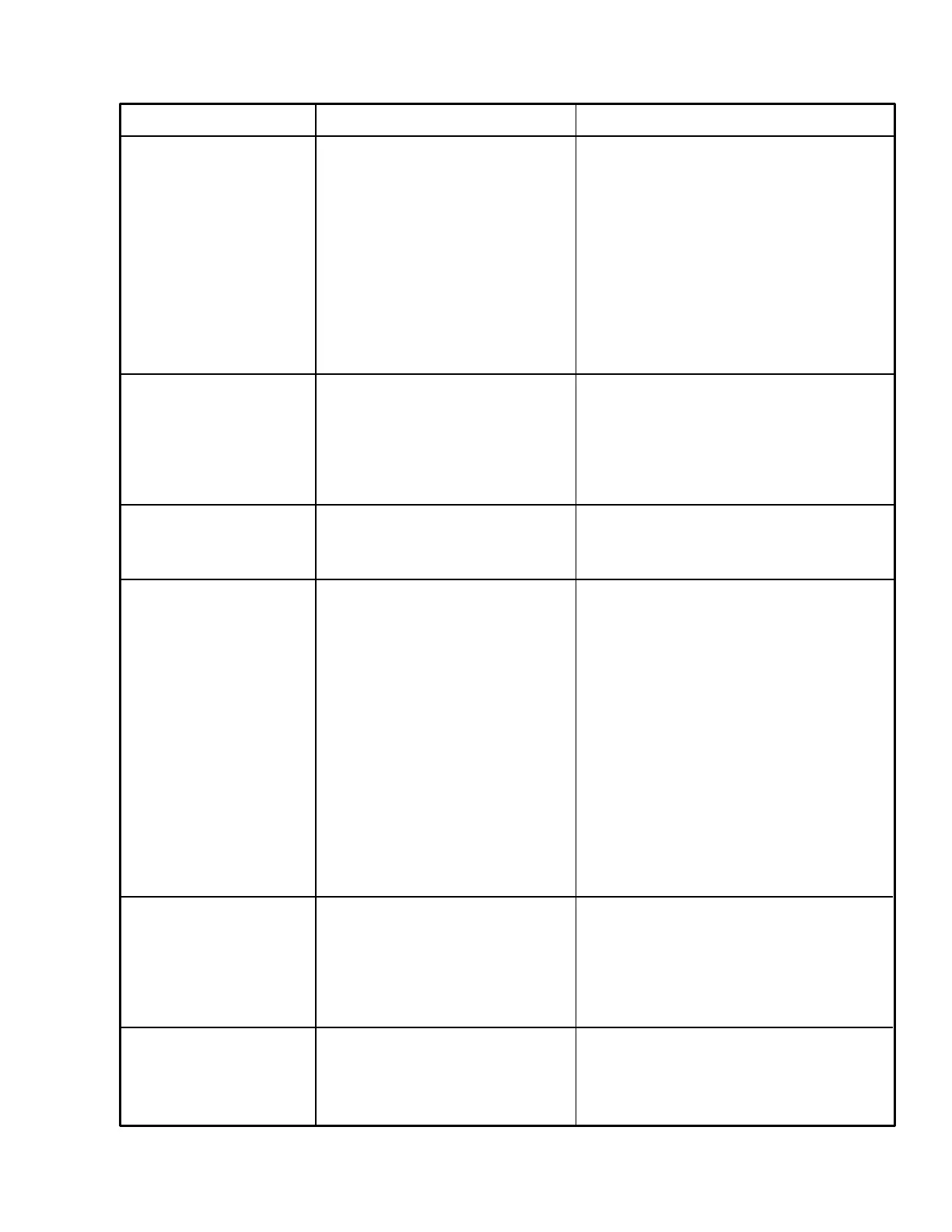

MALFUNCTION POSSIBLE CAUSE REMEDY

Compressor fails 4. Motor not running up to 4. Check power supply to motor

continued. speed. and correct as required.

5. Drive belts loose and 5. Replace and/or retention

slipping. drive belts.

6. Damaged or excessively 6. Repair or replace intake

worn intake valve. valve.

7. Air supply to compressor 7. Properly ventilate compressor

room or enclosure room or enclosure.

inadequate.

Compressor fails to 1. Control bleed orifice 1. Clean control bleed orifice.

pump (load) or is slow plugged.

to load after running

unloaded. 2. Sticky intake valve operating 2. Disassemble, clean or replace

parts. faulty intake valve parts as

required.

Compressor stops but 1. Faulty blow down valve. 1. Renew blow down valve.

air receiver/oil reservoir

does not blow down.

Excessive compressor 1. Clogged or restricted 1. Clean or replace line and/or

oil consumption. separator drain line or filter. filter.

2. External oil leaks. 2. Inspect for and correct all

external oil leaks.

3. Incorrect oil installed in 3. Refer to oil specifications.

compressor. Drain unit and install correct

oil.

4. Oil reservoir over filled. 4. Drain to correct oil level.

5. Low pressure operation. 5. Operate at correct pressure

(80 psi minimum)

6. Defective separator element. 6. Renew separator element.

Oil blows out blow 1. Clogged or restricted 1. Clean or replace line and/or

down valve when separator drain line or filter. filter.

blow down valve

actuates. 2. Defective blow down valve. 2. Replace blow down valve.

3. defective separator element. 3. Replace separator element.

Air receiver-oil 1. Incorrect or insufficient 1.

reservoir pressure control pressure due to:

relief valve actuates.

a. Clogged or restricted a. Clean replace supply

Loading...

Loading...