9. Service and maintenance

38

Procedure for changing the LC unit

a) Disconnect plug from lubrication system.

b) Unscrew lubricator (LC unit with drive and cover)

from the lubrication point.

c) Unscrew drive cover.

d) Remove drive from LC unit.

e) Check setting of decode switches (see Settings

section). (The decode switches are preset and

locked in the factory. They must not be changed.)

f) Place drive on new LC unit until the gears mesh.

Only use completely filled genuine CompAir LC

units.

g) Screw down drive cover to LC unit (hand tight).

h) Remove seal plug from LC unit.

i) Screw lubricators into lubrication point (hand tight).

j) Reconnect plug in drive.

k) After a reset, the lubrication system starts the

applicable pause time.

l) Check function: A green LED indicates a continuous

signal if the screw air compressor unitʼs drive motor

is running.

m) The lubricant in one LC unit MLS 120 is sufficient for

approx. 4000 Oh (only applies to the screw air

compressor range D110H RS) (this figure doesnʼt

include compressor downtimes).

9.2.4 Function display on lubricator

The LEDs for the function display are located on the

control plate and can be viewed through the transparent

cover.

The function display is only active if the screw air

compressor unitʼs drive motor is running.

The lubricators are fitted with one red and one green

LED. These LEDs signal the following operating modes

or faults to the operator.

1) When the lubricator issues this signal, the following

message is output on the compressor control:

[Warning: Mot.lubr. sys] (also refer to the operating

instructions for the compressor control DELCOS XL).

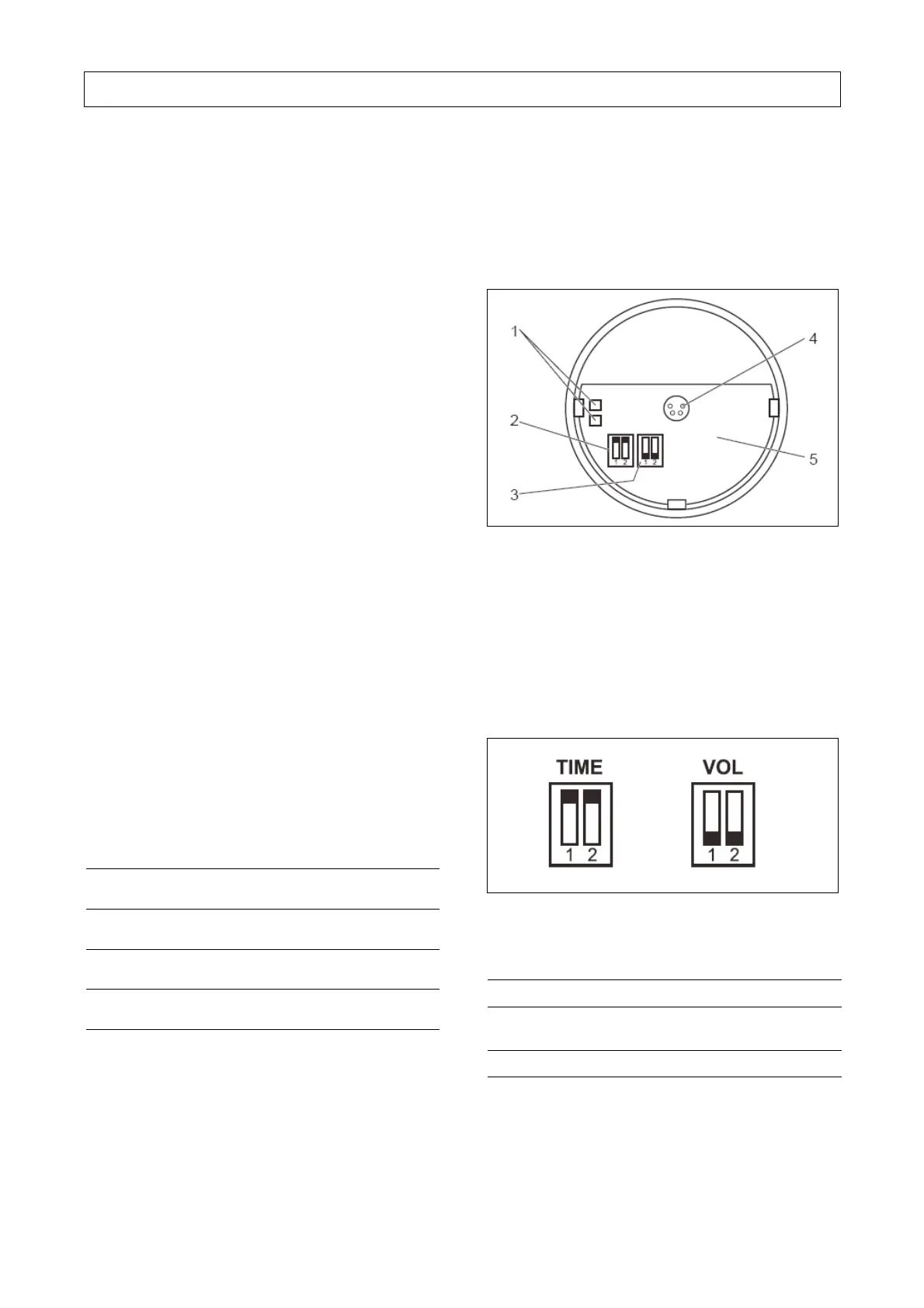

Settings available on the control plate

There are two decode switches on the control plate.

The protruding switches inscribed with “TIME” are for

setting the dispensing volume and the recessed

switches inscribed with “VOL” are for setting the size of

the LC unit.

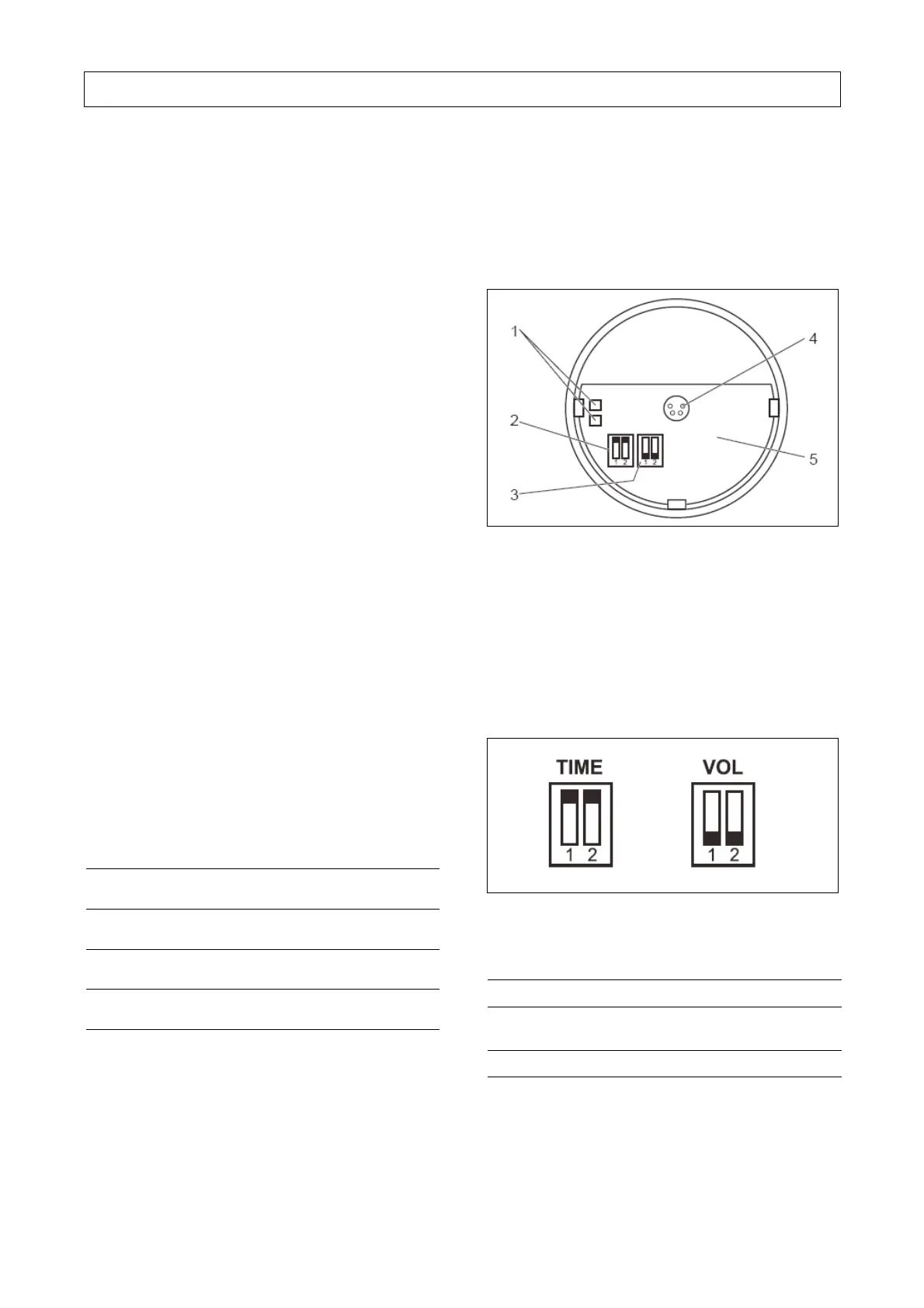

Fig. 19 a

1 Function display (LED)

2 Protruding “TIME” switches

3 Recessed “VOL” switches

4 Plug connection

5 Plate

The following setting applies to the screw air

compressor range D110H RS / 50Hz + 60 Hz with a

standard electric motor:

Fig. 19 b)

Loading...

Loading...