Under unfavourable local conditions, we recommend

the installation of venting ducts. However, the velocity

of the cooling air should not exceed 5 m/s. We

recommend a minimum duct cross-section of approx.

0.15 m

2

for L07-L11, 0.2 m

2

for L15-L22.

Important

The stated minimum cross-section refers to a

maximum duct length of 5 m/16.4 ft and a maximum

of one bend. In the event of differing values (over

5 m/16.4 ft, more than one bend, filter cartridges,

screens, etc.), please contact your technical

adviser.

CompAir screw compressors are rated for ambient

temperatures and cooling temperatures of +1°C/

33.8°F to +45°C/113°F. In the case of temperatures

other than the above limiting values, please consult

your technical adviser.

Note

In order to ensure a good heat dissipation, auxiliary

fans should be rated to process approximately 15 to

20% more air volume than the total cooling air

quantity required by the compressors installed in the

compressed air station.

6.2 Compressed air connection

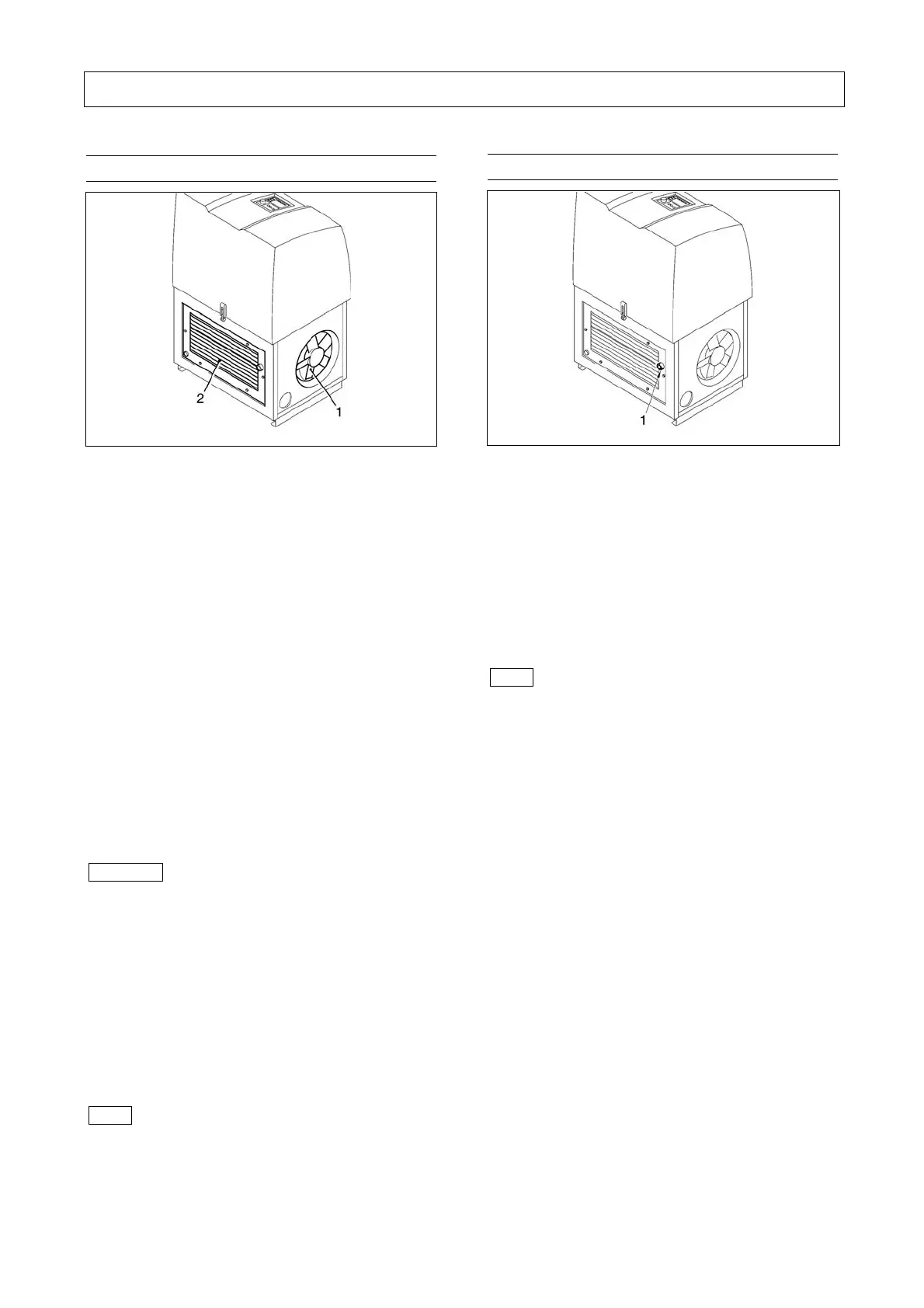

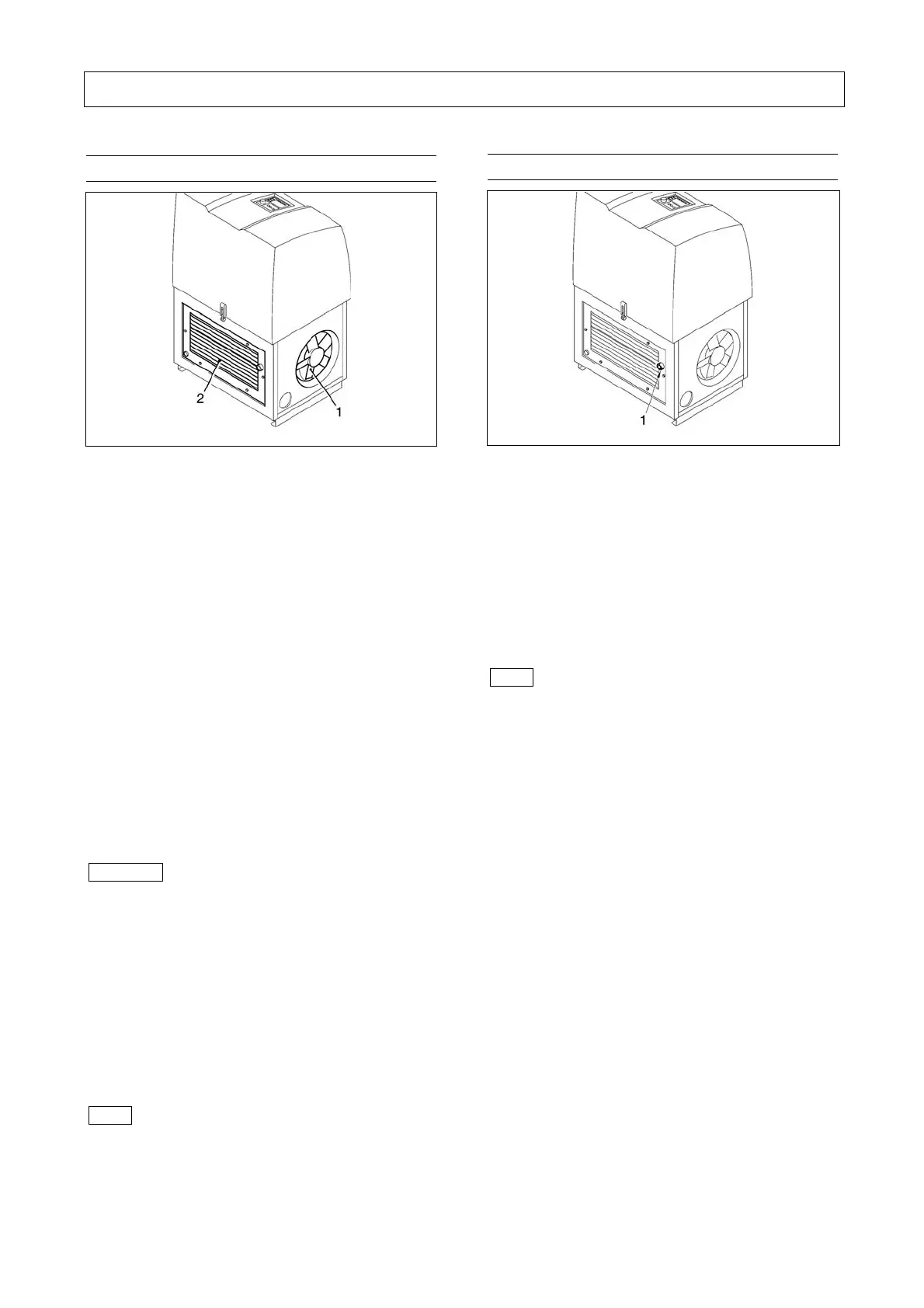

Fig. 10

1 Compressed air connection

The compressed air line system is connected at the

compressed air supply of the screw compressor

( - 1 - Fig. 10).

For this you should use a flexible connection

(e.g. compressed air hose, compensator).

L07-L11 sleeve G 3/4"

L15-L22 sleeve G 1"

Note

After-coolers, separators, collecting reservoirs and the

compressed air lines must be equipped with drain

facilities at their lowest points to drain collected liquids.

These facilities have to be fitted to allow the observance

of the draining of such liquids.

Hand-operated drain facilities have to be actuated in

accordance with the operating instructions.

Automatic drain facilities have to be checked for proper

function at regular intervals. When draining

condensates into a collecting line, which also collects

the condensate from other machines, make sure that

the collecting line is free from back pressure at all lines.

Condensate may contain oil! When draining

condensate, observe the corresponding regulations for

waste water disposal.

Loading...

Loading...