9. Service and maintenance

43

Change the oil fine separator as follows:

• Switch the screw compressor unit off and make sure

that it is depressurised and no voltage is supplied.

• Unscrew the fine separator cartridge (-1- Fig. 19)

using an appropriate tool

• Dispose of the fine separator cartridge according

tothe regulations

• Oil the gasket of the new fine separator cartridges

lightly

• Screw on the new fine separator cartridge and

tighten manually (take notice of the instructions on

the fine separator cartridge)

• Check for leakage

• Check oil level (see chapter 6.5)

• If required, top up oil.

Changing intervals for oil fine separator cartridge

The operating conditions (e.g. coolant temperatures),

the operating modes and the quality of the intake air

(e.g. content of dust, content of gaseous foreign matter

such as SO2, solvent vapours, etc.) have a strong

influence on the service life of the filters (air filters, oil

filters, fine separators).

Where such conditions exist the filter element may

require changing more frequently.

9.7 Change of air intake filter

Danger

Only perform checks and carry out work on the

screw compressor when the unit is out of operation

and depressurized!

Important

Never operate the screw compressor unit without

the air filter (even a short operating time without

this filter can result in considerable damage to the

machine)!

A clogged air filter must be cleaned or replaced when

the maintenance point has been reached.

Check the air filter for accumulated dust at least once a

week or, if required, daily.

During maintenance work, take care that no dirt enters

the clean air side of the air filter.

9.7.1 Change of air intake filter L07-L11

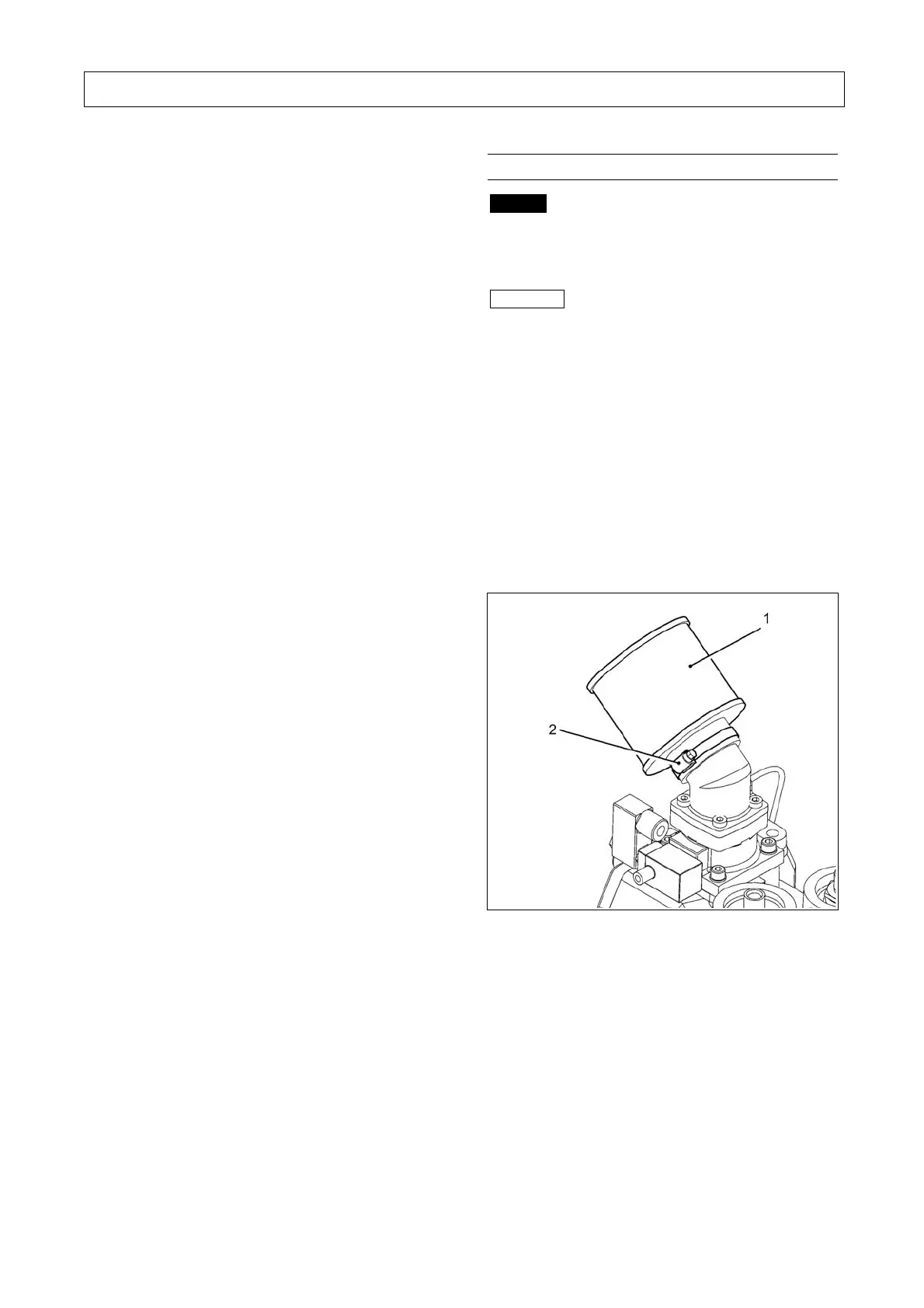

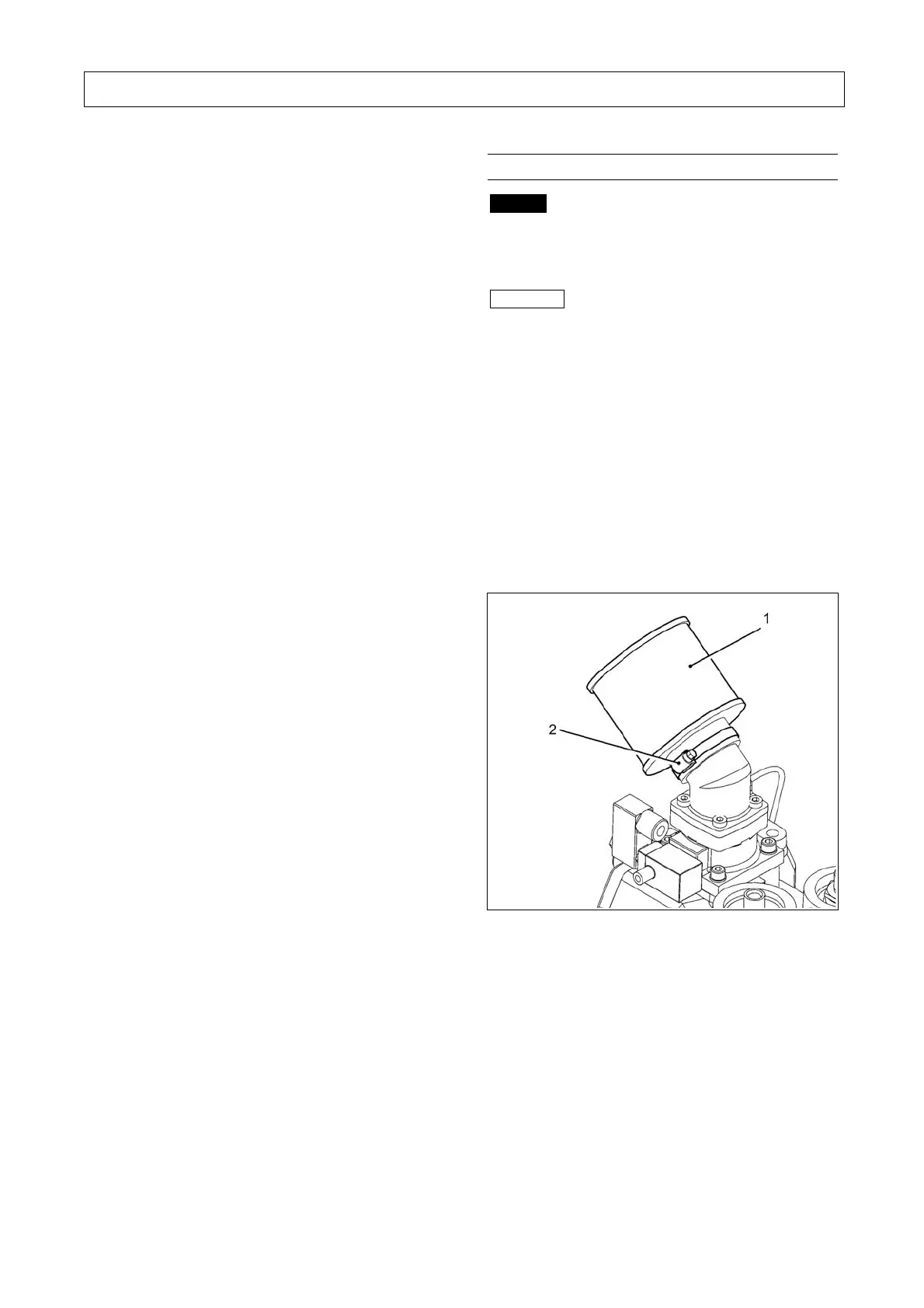

Fig. 20 L07-L11

1 Air intake filter

2 Fixing clip

Change the air filter as follows:

• Loosen the fixing clamp ( - 2 - Fig. 20)

• Pull off the air filter ( - 1 - Fig. 20) and replace it with

a new one

• Put the air filter on and tighten the fixing clamp

( - 2 - Fig. 20)

Loading...

Loading...