6. Preparations for commissioning

31

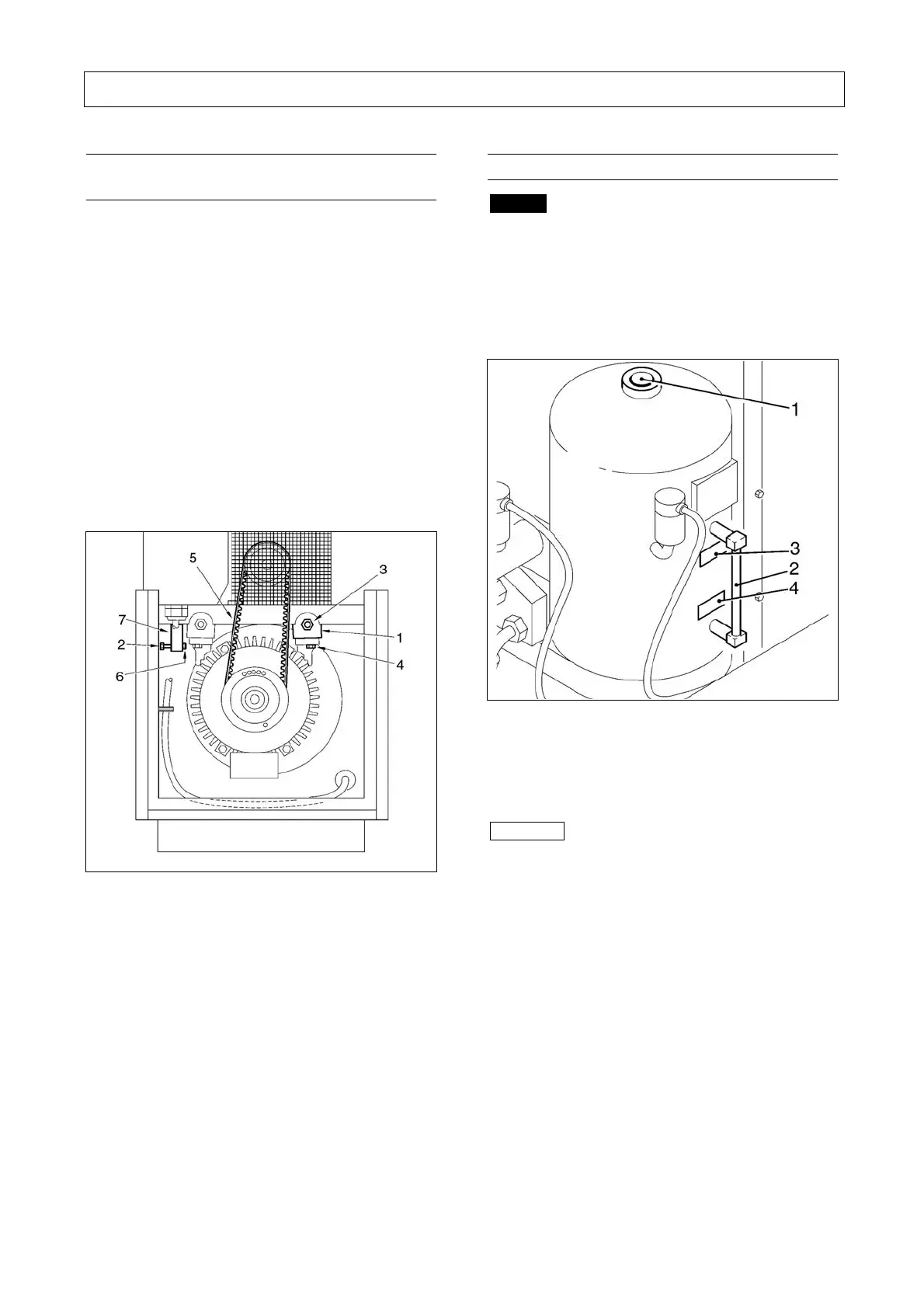

6.4 Electric motor fasteners for secure

transportation

Fasteners used for securing the electric motor (- 1 - Fig.

13) during transportation must be removed prior to

commissioning.

To remove the fasteners, proceed as follows:

• After the panel has been removed, support the

motor by screwing the belt adjusting bolt (- 2 - Fig.

13) clockwise until it touches the motor.

• Loosen the fastening screws (- 3 - and - 4 -Fig. 13)

and remove the fasteners

• Check V-belt (- 5 -Fig. 13) is correctly placed in the

in V-belt pulleys

• Screw the belt adjusting bolt back until it reaches

the lock nut (- 6 -Fig. 13) on the holder (- 7-Fig. 13);

securely fasten the motion screw (anti-clockwise)

Fig. 13

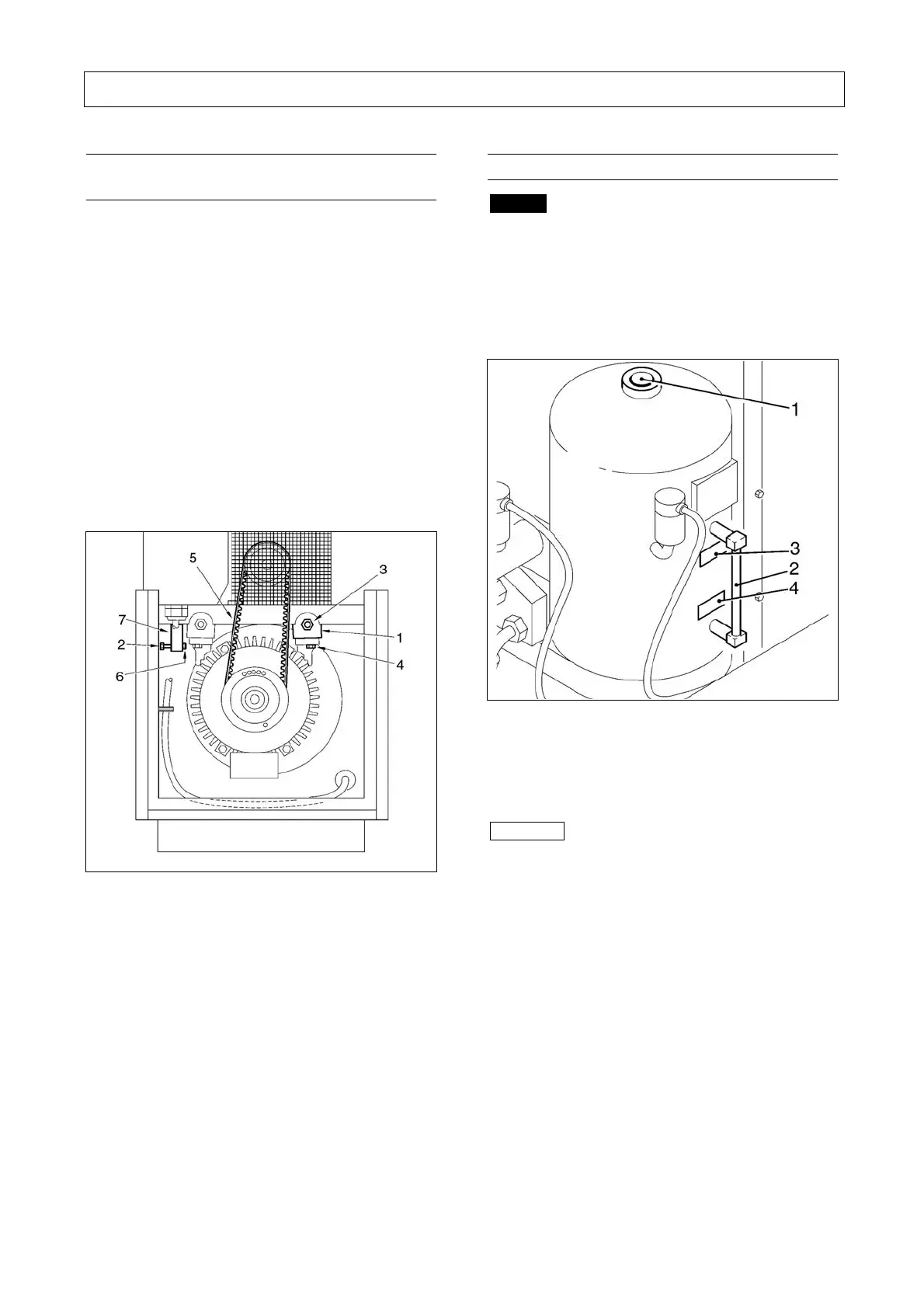

6.5 Oil level check

Danger

Only check the oil level when the screw

compressor unit is out of operation and

depressurized!

The pressure reservoir can be under pressure and

the oil hot. Warning: Danger of scalding!

Do not spill oil! Check for leakage!

Fig. 14

1 Oil filler cap R1"

2 Oil-level indicator

3 Maximum oil level

4 Minimum oil level

Important

Do not mix oils of different specifications.

Machines which are delivered without oil must first

be filled to the max. mark in the pressure reservoir

sight glass (see also chapters 9.4 and 9.14)

Check the oil level as follows:

• Switch off the screw compressor unit by pressing

the button

(Fig. 16).

• Wait at least 5 minutes for the oil to settle and for

the air to disperse

• The oil level is checked with the help of the

transparent plastic tube at the pressure reservoir

(- 2 - Fig. 14) after every stop and at regular

intervals. If required, top up oil

Also see chapter 8 “Service and maintenance”

Loading...

Loading...