MODEL 2200

www.comtecltd.com For Kasco Corp use only.

1

INTRODUCTION

he COMTEC Model 2200 Press forms pie, cheesecake, hors d’oeuvres and

other specialty crusts in round and non-round containers. This Press can

form bottom crusts ranging in size from 1-1/2 inches (38 mm) to 12 inches

(300 mm) diameter; top crusts to 11-5/8 inches (295 mm) diameter. The

quality of the crusts formed with this Press exceeds that obtained with sheeted

methods.

The Model 2200 is a hydraulic machine that uses custom dies to form dough. Each size

and type of crust requires a separate, custom die. Dies that form bottom crusts are

manufactured to work with a specific pan, chosen by the customer.

To form a crust, a dough portion is placed in the

center of the pan to be used. The pan is then

placed in the lower die half. USING TWO

HANDS, ONE HAND ON EACH LEVER, PRESS

BOTH LEVERS

to bring the lower die half up

against the upper stationary heated die half.

After a short dwell (for example, 2 seconds) the

levers are released, bringing the lower die half

down. The formed crust is then removed from

the die. ONLY THE OPERATOR OF THE

HANDLES IS TO LOAD THE PAN WITH DOUGH

PORTION INTO, AND REMOVE THE FINISHED

CRUST FROM THE PRESS

.

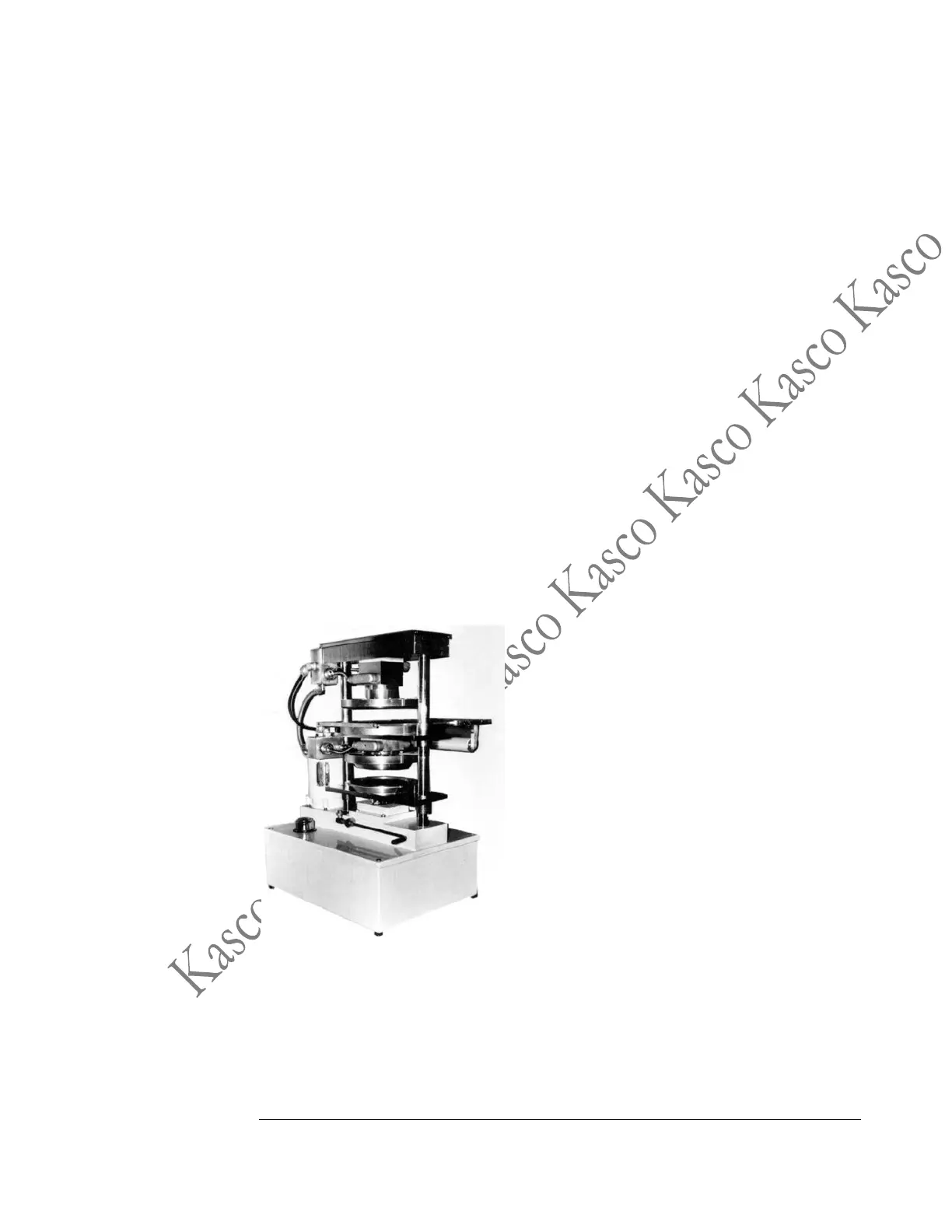

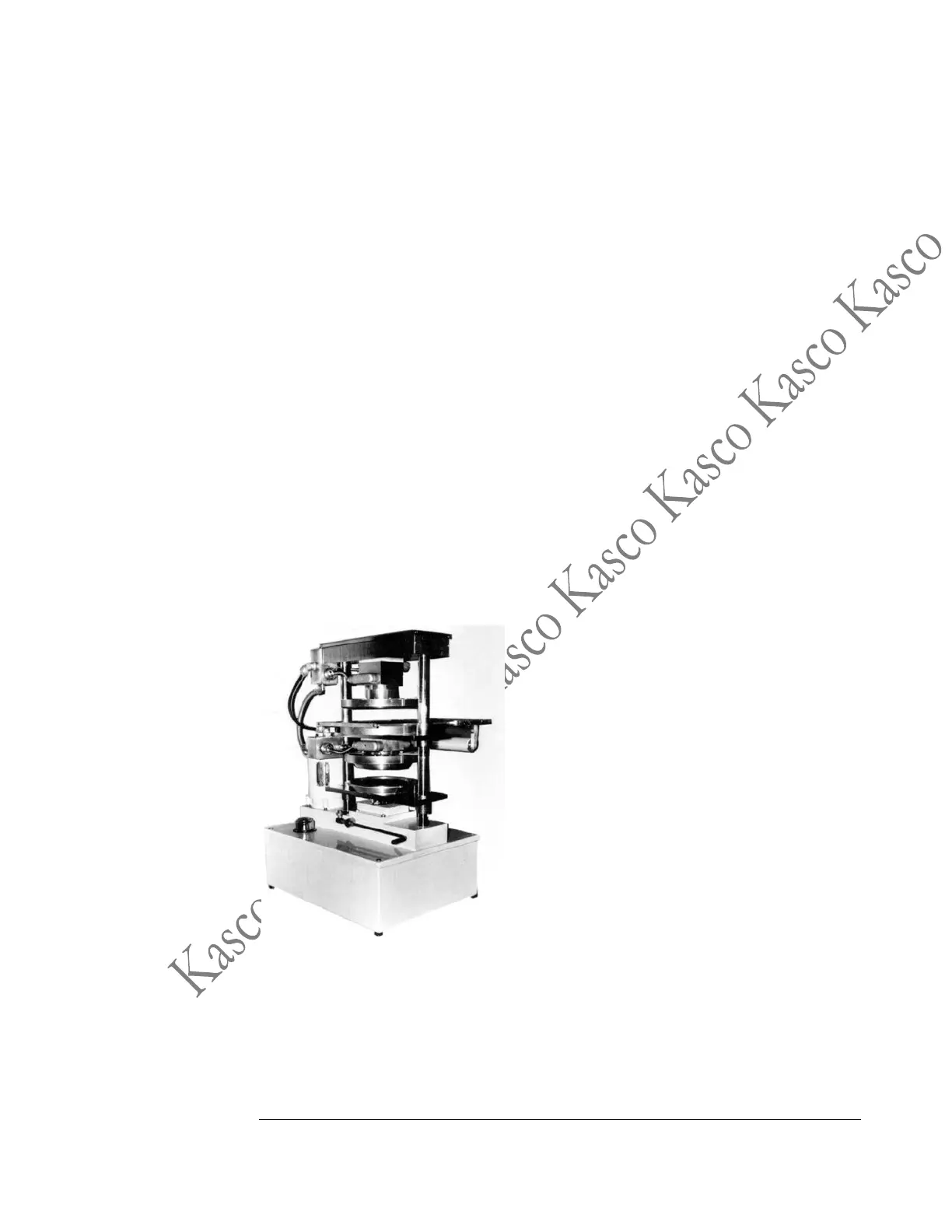

Figure 1 Front View of Machine

Loading...

Loading...