6

MODEL 75T

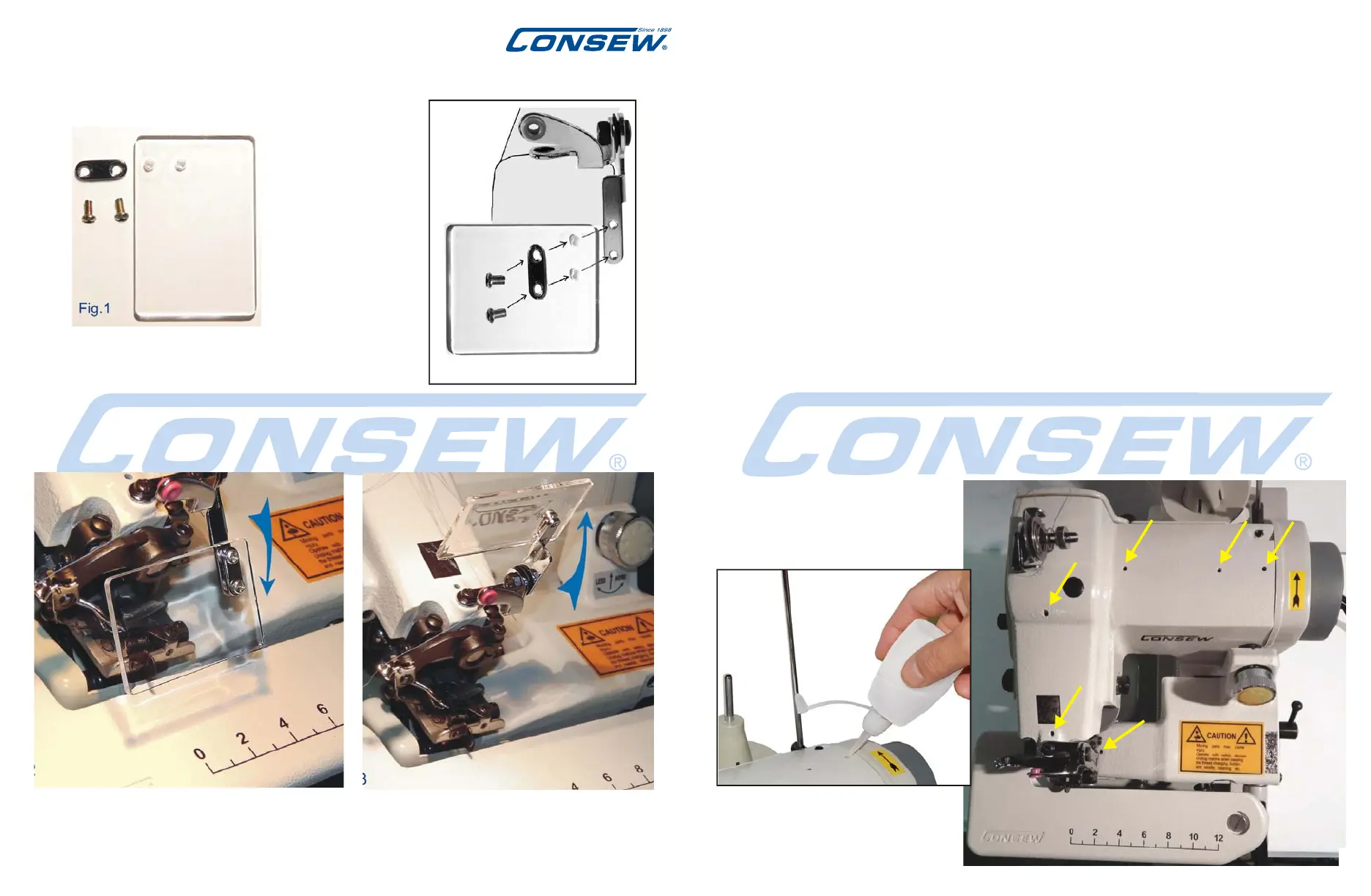

E. Optional Clear Acrylic Shield

(provided with machine - Fig Shield1)

To Install:

Using the two small

screws provided,

screw through the

metal plate and

the shield into the

two screw holes in

the swing arm

located just to the

right of the needle

assembly.

(Fig Shield 2)

In the “Down” position (Fig.Shield3)

the shield helps keep fingers

out of the needle area

In the “Up” position (Fig.Shield4)

it is out of the way

Fig. Shield 3

Fig. Shield 4

Fig. Shield 1

Fig. Shield 2

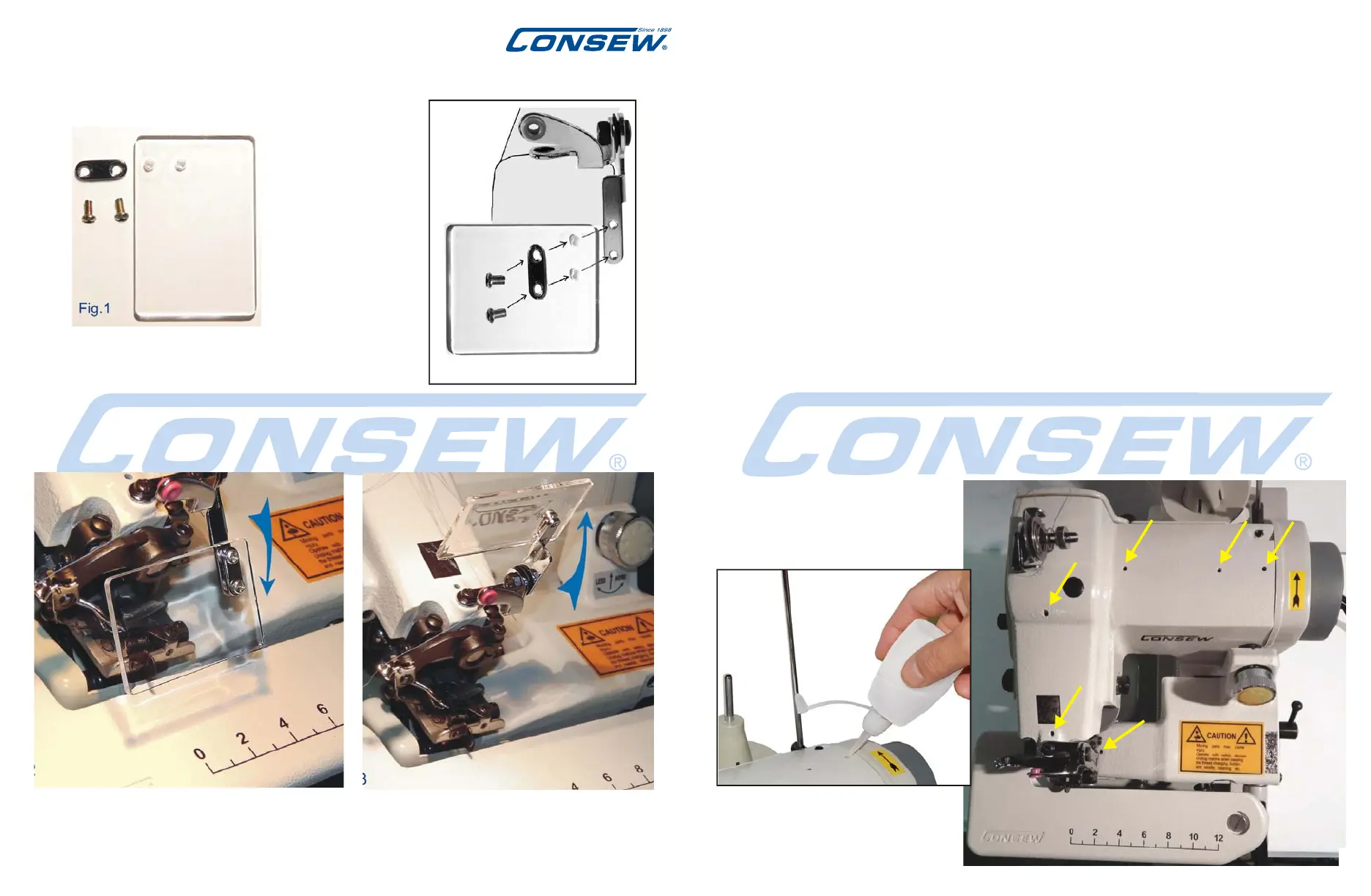

Lubrication is important for the trouble-free operation and long service life of the

machine. Therefore, after setting-up machine as per instructions, you should lubricate

it before using.

A convenient oil dropper filled with fine machine oil is provided with the tool kit.

(Use a pin to pierce the tip of the spout. Be sure to snap the cap on tightly after

opening to avoid leakage. You may want to keep it in a small resealable plastic bag

when storing.)

Lubrication Regimen

Carefully place a drop sewing machine oil into all the holes indicated by arrows on

Fig.7. There are 6 of them. Remember to give the machine a wipe down to remove

any residual oi1 that might stain your work.

As a part of regular daily maintenance, you should oil the 6 oil holes with a drop of

machine oil (in Fig.7) before starting work.

Tip: It is suggested that you do this at the end of the previous days work because

this would allow any excess oil to settle and with a quick wipe the machine will be

clean and ready to go the next day.

2. Lubrication (Fig.7)

Fig.7

OILING POINTS

Note: Internal Lubrication is

covered in sections

12 and 13.

7

Loading...

Loading...