Battery Test Procedure

The condition of the control battery is tested by depress-

ing the BATTERY TEST key on the operator panel. No

external current/voltage meter is necessary for testing.

The control performs a self-test every 12 hours or when initi-

ated by an external command. When a battery test is initiated,

the spurious charge is first drained to allow the battery voltage

to equalize. A 10-ohm, 55-watt resistor is then placed across

the battery terminals and a voltage drop is calculated. If the

drop from the equalized voltage to the test voltage exceeds 2

volts, then the CHECK BATTERY LED is illuminated.

To perform a battery test:

1. Using the NEXT and BACK keys, scroll through the

LCD display to Screen 31, the Battery Monitor screen.

2. Record the NORMAL VOLTS and NORMAL CUR-

RENT readings from the screen.

Note: Voltage should be between 25 to 31 volts with

higher readings at colder temperatures. Under nor-

mal conditions with ac connected and the battery

trickle charging, the current should read less than

20 mA. With ac connected and in bulk charging

mode, current will range from 12 to 600 mA. With ac

disconnected and the battery supplying the load,

current will read -180 mA to -600 mA depending on

accessories connected.

3. Momentarily, press the CHANGE/LAMP TEST key,

then BATTERY TEST key.

Note: AC power can be either connected or disconnected.

4. Record the TEST VOLTS reading from the LCD and

the status of the CHECK BATTERY LED. Service the

battery if the CHECK BATTERY LED is illuminated.

Testing Procedure for Uninstalled

Battery

The entire process should be conducted in a clean envi-

ronment, such as a repair shop.

Refer to Table 4 and follow this procedure to perform a

bench test on a control battery in a service shop:

1. Remove the control from service. Refer to Remove

the Control from Service procedure within the Test-

ing section of this manual.

2. Remove the battery from the control and carefully

transport it to a suitable service facility.

3. Measure battery voltage.

4. Apply test load and measure battery voltage after 5 sec-

onds of load to determine voltage drop. Refer to Table

4 for Bench Test Load Condition.

5. Remove test load.

If the battery fails the test or is at least four years old, it

should be replaced. Refer to Table 4 for battery catalog part

numbers.

Battery Charging

If it is not possible to charge the battery with the control’s

built-in charger, a KA43ME7001 (120 Vac) portable bench

type battery charger is available. Refer to Service Infor-

mation S280-79-14 KA43ME7001 Portable Lead Acid

Battery Charger Instructions for additional information.

Use adapter KME5-325-1 to connect the two 12 volt bat-

teries to the KA43ME7001 charger. Charge the battery

with a KA43ME7001 (120 Vac) portable charger.

Note: A red LED indicator on the body of the charger illumi-

nates when charging.

The charger senses when the battery voltage reaches

2.27 volts per cell, then the charge rate reduces to main-

tain a trickle charge.

The red LED flickers to indicate the battery has reached a

full charge. This process can take up to 24 hours.

S280-42-3

43

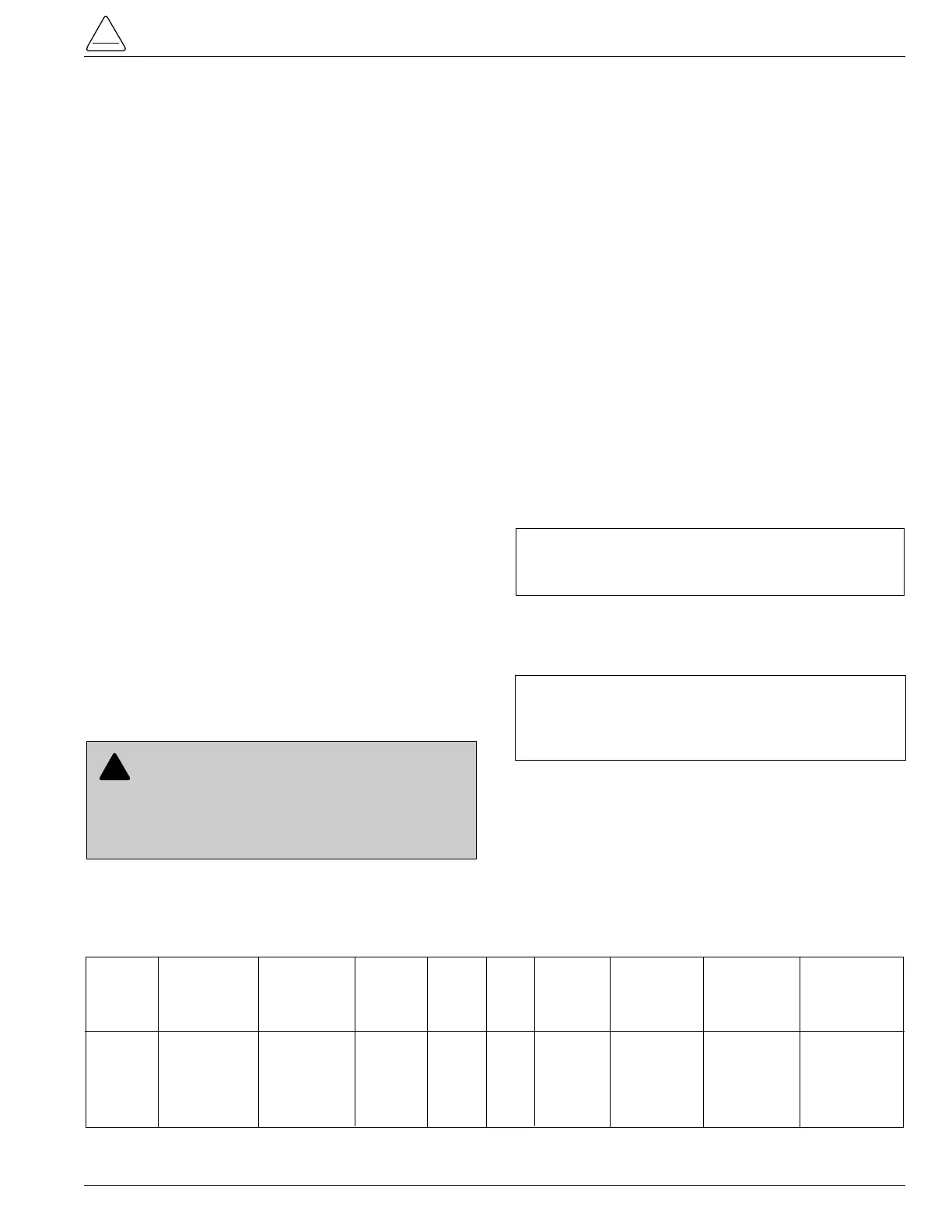

TABLE 4

Battery Bench Testing and Replacement Information

The Form 5/Triple-Single control batteries have different dimensions; therefore, if the replacement battery ordered is a different brand

than the original battery, a kit with mounting hardware may be required to accommodate the replacement battery size.

Bench Acceptable

Battery Test Load Voltage Drop Battery

Control Catalog Amp/ Condition at end of Battery Replacement

Type Battery Part # Voltage Type Hour for 5 sec. Test Load Tester Kit

Form 5/ Hawker KME5-134-1 24v Lead 13 5

Ω,

2v BATTERY KME5-709-17

Triple- Genesis or (two Acid 55 watt or less TEST or

Single Sonnenschein KME5-134-2 12v 18 hot key on KME5-709-12

high or batteries) control panel or

capacity Yuasa KME5-134-3 12 KME5-709-13

CAUTION:

Recloser misoperation. The control

must be removed from service before disconnecting

the control battery. Disconnecting the control battery from an

in-service control may cause recloser misoperation (uninten-

tional operation). Failure to comply can result in equipment

damage or personal injury. T213.4

Loading...

Loading...