Types VW and VWV Maintenance Instructions

4

Vacuum Interrupters

Circuit opening and fault interruption is achieved within the three

sealed vacuum interrupters. The moving contact rod assemblies

are operated by the recloser mechanism to open and close the

vacuum interrupter contacts. Berylium copper garter springs are

used in the current exchange assemblies to provide a multi-point

low resistance current path between the stationary bushing leads

and the moving contact rod of the interrupters.

Closing Solenoid

The moving contacts of the interrupters are closed by the closing

solenoid, which also extends the opening springs in the head

mechanism. This solenoid is energized for only a few cycles dur-

ing each closing operation when it is momentarily connected

across phases B and C.

Closing Solenoid Contactor

Mechanically operated by the head mechanism, the snap-action

contacts of the closing coil contactor complete the high-voltage

circuit to the closing solenoid for each closing operation.

Hydraulic Pump and Lockout Piston

The hydraulic pump counts the number of times the recloser trips.

With each trip the pump piston is pushed into the pump cylinder,

oil is forced through the lockout cylinder check valve into the lock-

out cylinder. This causes the lockout piston to be raised one step.

When the recloser resets the pump piston is pulled back to the

top of the pump cylinder and oil is drawn in through the intake

check valve.

If the recloser trips again the pump piston will actuate causing

the lockout piston to be pushed up another step. This cycle will

repeat until the recloser locks out. Once locked out the quick

reset rod is mechanically raised allowing the lockout piston to

quickly resettle. If the recloser does not lockout, the lockout pis-

ton will resettle gradually (at a rate of approximately 90 seconds

per accumulated operation at 25°C).

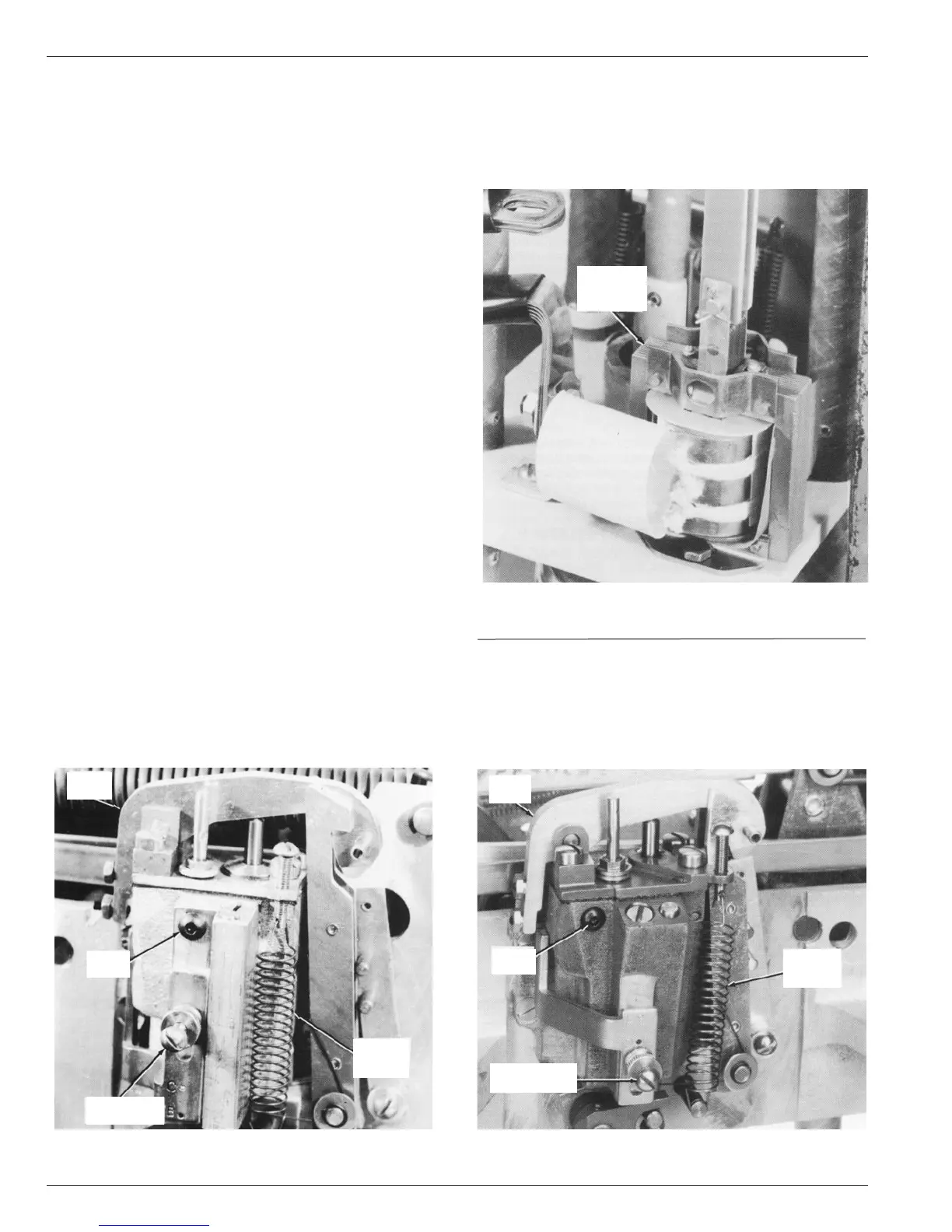

Series Trip Solenoids

The series trip solenoids (Figure 3) are connected in series with

the vacuum interrupters, each carries full line current. When line

current exceeds the minimum trip rating of a coil, by approxi-

mately 200 percent, the plunger is drawn into the solenoid. Near

the end of the plunger stroke the recloser mechanism trips.

When the recloser mechanism is sequenced to the delayed

operation phase, the speed of plunger movement is restrained

by a time-delay unit. The restrained plunger movement pro-

vides a fixed time delay before the recloser mechanism trips.

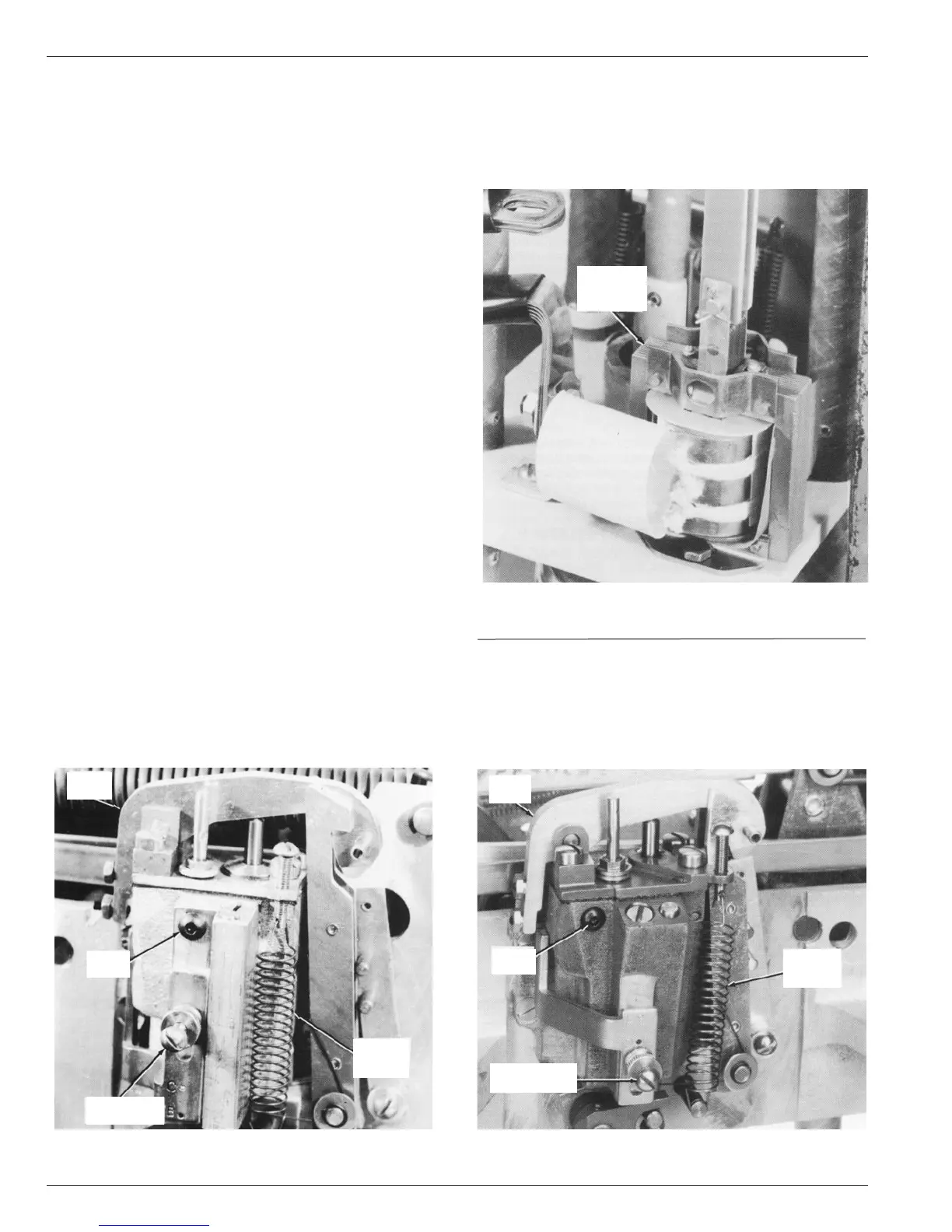

Time Delay Unit

When the mechanism is sequenced to a delayed operation the

latch assemblies of the trip solenoid plunger linkages are

engaged with the arms on the sealed time-delay units, Figure 4a

and 4b. Trip solenoid plunger movement is then restrained by the

time-delay unit, which provides a consistent delay action by forc-

ing hydraulic fluid through a calibrated orifice within the unit.

Figure 4a.

Time delay unit (old).

82020KMA

DELAY

ARM

FILLER

PLUG

ADJUSTMENT

SCREW

MINIMUM

TRIP

SPRING

Figure 3.

Series Trip coil.

84612KMA

SERIES

TRIP

SOLENOID

Figure 4b.

Time delay unit (new).

86780KMA

FILLER

PLUG

DELAY

ARM

MINIMUM

TRIP

SPRING

ADJUSTMENT

SCREW

Loading...

Loading...