S280-30-7

5

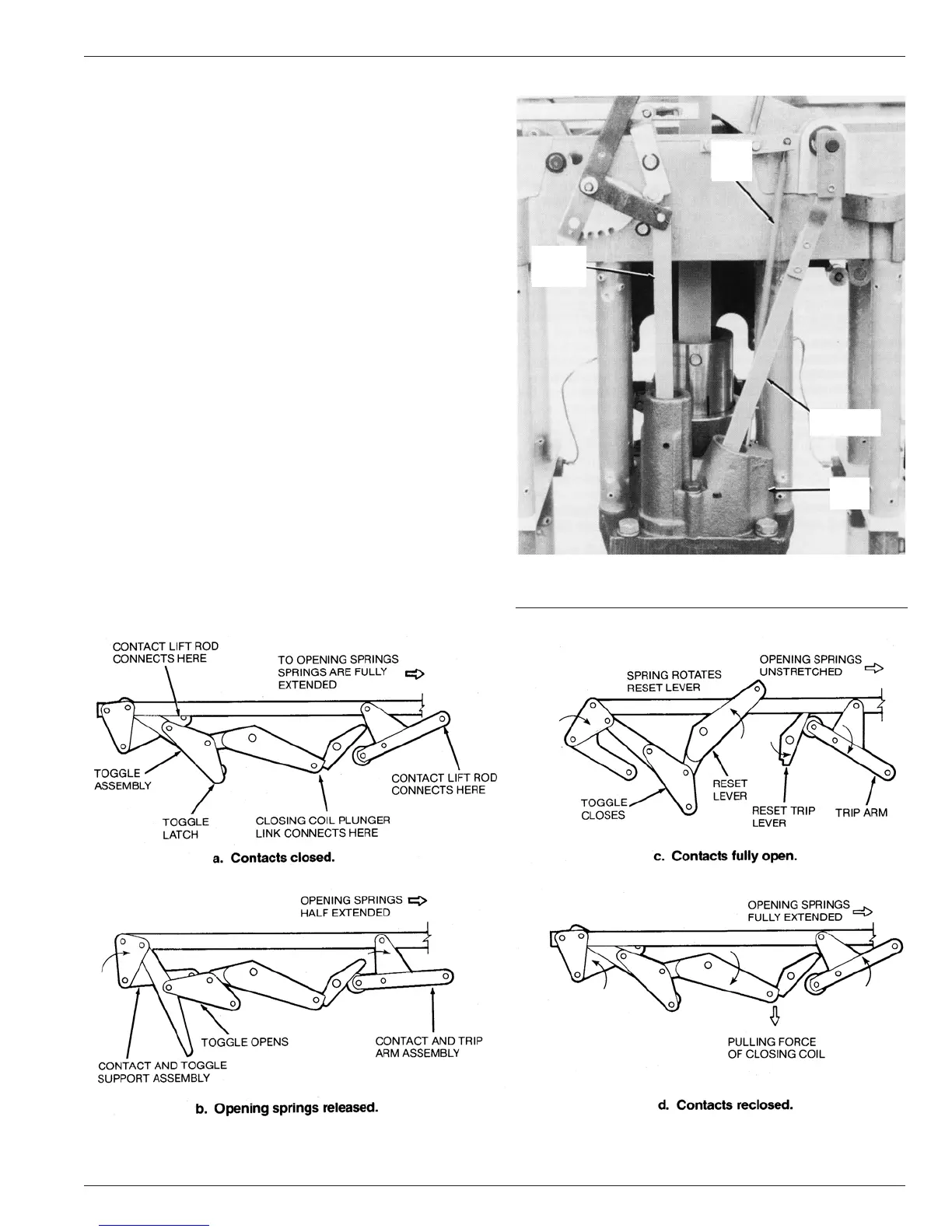

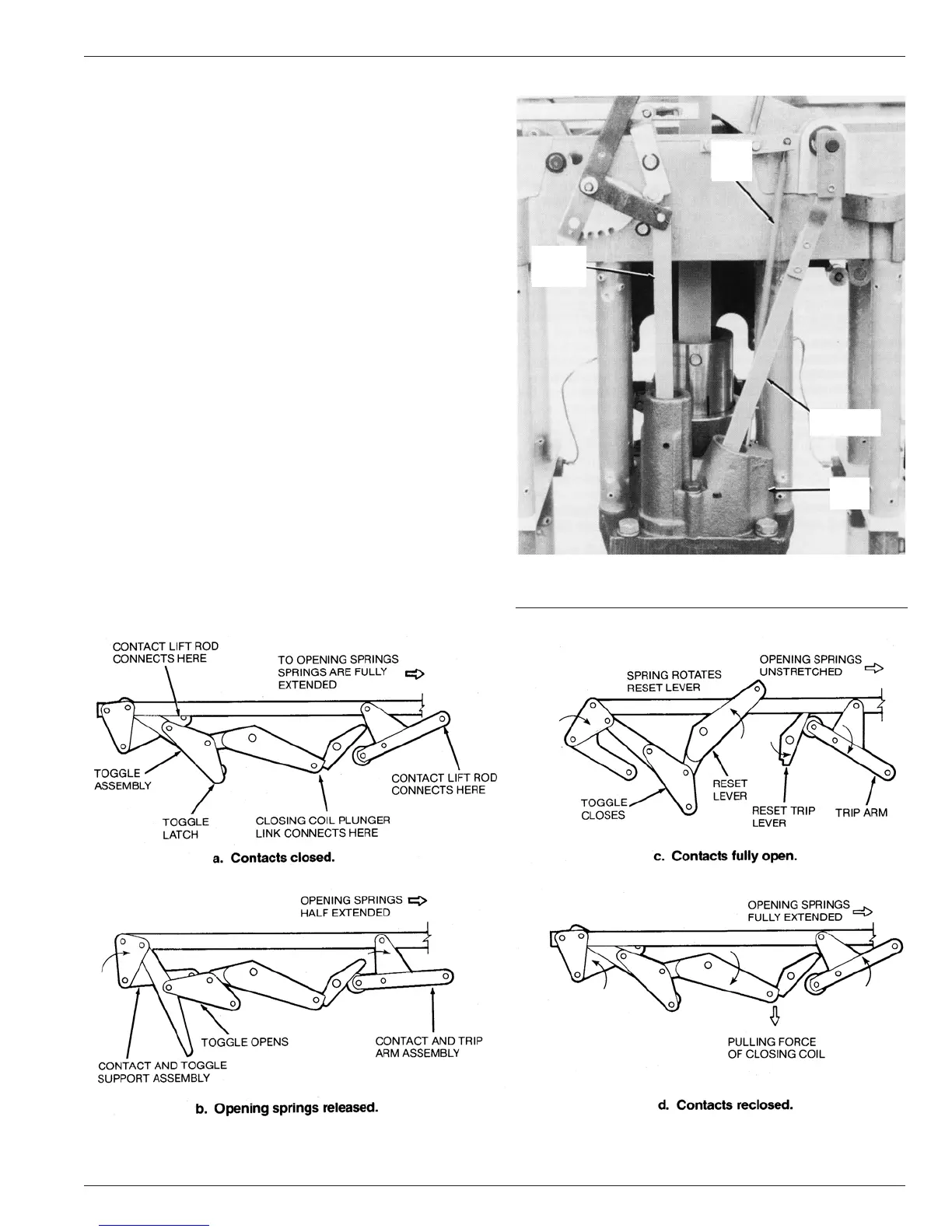

Figure 5.

Head mechanism lever arrangement

MECHANISM OPERATION

The operating mechanism, mounted in the head, opens and

closes the vacuum interrupter contacts. Contact opening is initi-

ated by a series trip solenoid which triggers the trip mechanism

to release the loaded opening springs. Contact closing is per-

formed by the closing solenoid which also charges the opening

springs and resets the mechanism for the next trip operation.

The basic operation of the mechanism is shown in Figure 5.

With the interrupter contacts closed (a), the opening springs

are fully extended and the mechanism is in the reset state. When

excessive current levels are passing through the series trip coil

the solenoid plunger is actuated. The trip solenoid plunger oper-

ates the toggle latch, releasing the toggle. This action releases

the opening springs (b) which starts the contact bar assembly in

motion. The spring-biased reset lever rotates to snap the toggle

closed. This action of the reset lever also pulls the plunger out of

the closing solenoid. At this point the interrupter contacts are

fully open (c) and the mechanism is in the open state. When the

closing solenoid plunger reaches the top of its stroke it mechan-

ically closes the closing coil contactor which energizes the clos-

ing solenoid. As the plunger is drawn down into the coil the reset

lever is pulled back and latched in its original position. The inter-

rupter contacts are closed (d) and the opening springs are

extended. The mechanism is now ready for another opening

operation.

HYDRAULIC CONTROL SYSTEM OPERATION

The hydraulic pump, associated cam, and linkages regulate the

number of fast and delayed operations, count the operations to

lockout, and initiate lockout after a preset number of operations.

The hydraulic pump (Figure 6) is linked to the closing-solenoid

plunger and is pushed downward with each return operation of

Figure 6.

Hydraulic pump.

86796KMA

TRIP

PISTON

ROD

QUICK

RESET

ROD

HYDRAULIC

PUMP ROD

PUMP

BODY

Loading...

Loading...