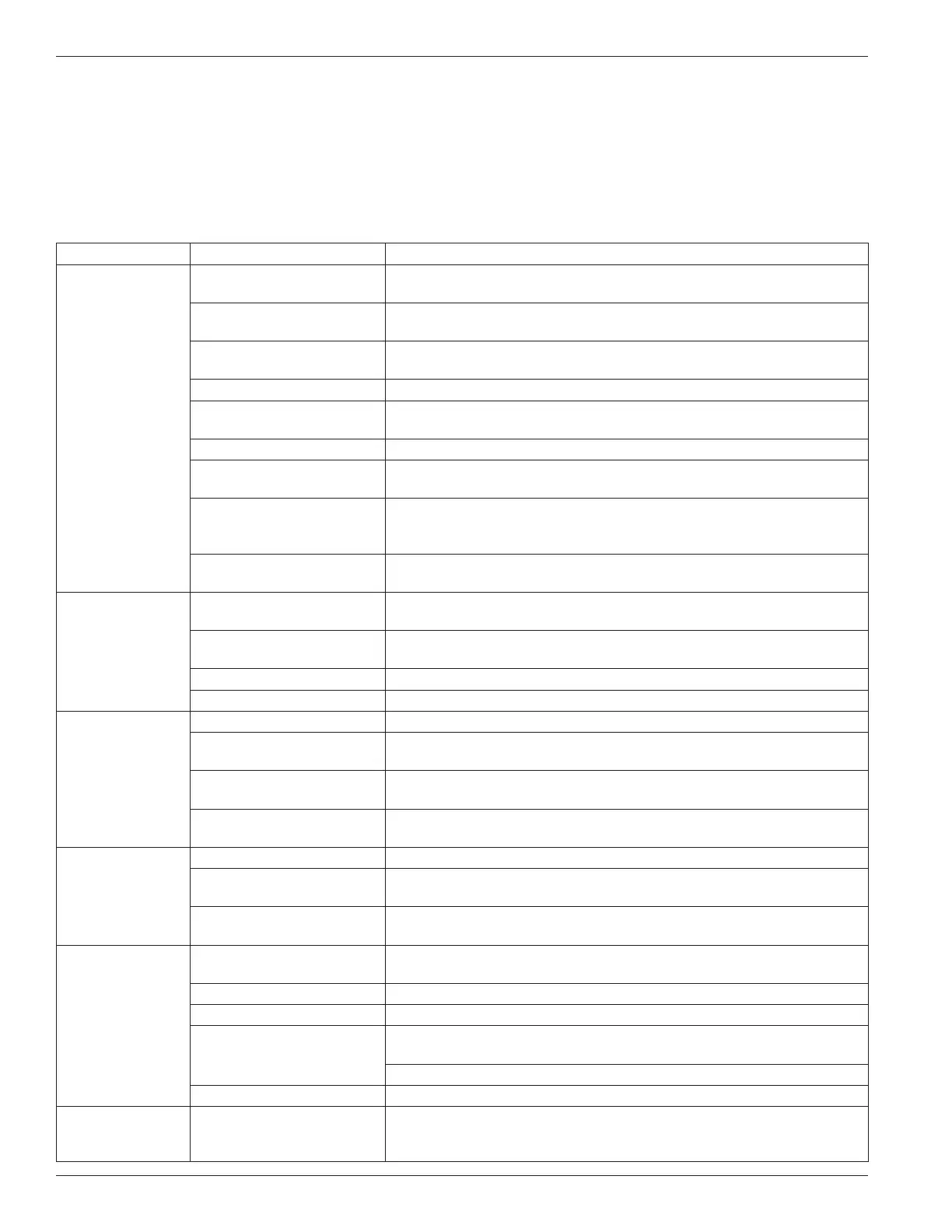

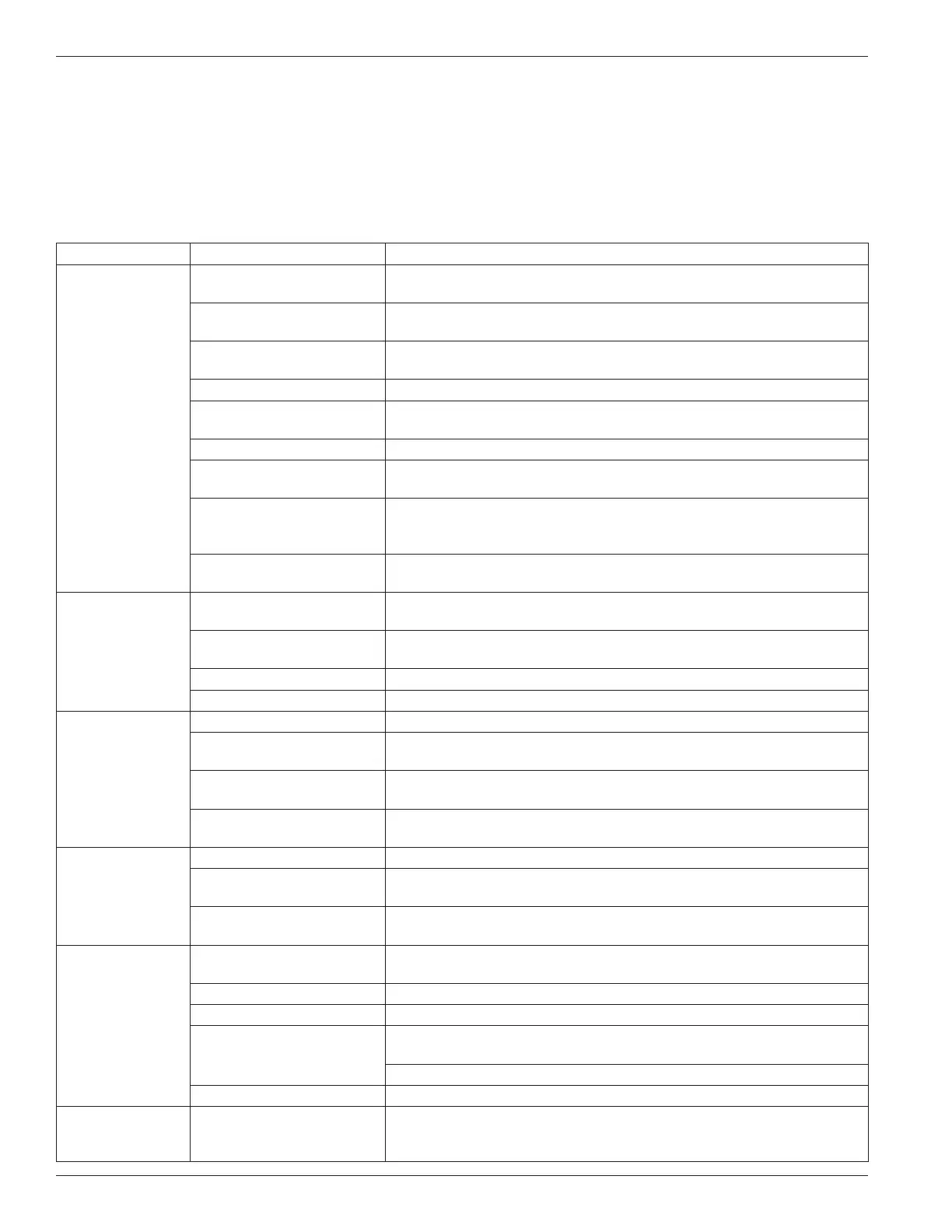

G. Troubleshooting Guide

Appendix G—Troubleshooting Guide

Symptom Probable Cause Remedy

Low capacity Pump speed too slow Check engine speed and PTO ratio. Consult pump performance curve.

Use tachometer on pump if speed is questionable.

High differential pressure Restriction in discharge piping or hose too small. Vapor equalization lines

too small or not used.

External bypass valve stuck

open or set too low

Readjust, repair, or replace valve.

Clogged strainer Clean strainer.

Suction pipe too small or

restricted

Indicated by pump inlet pressure dropping several pounds when pump is

started. Remove restriction or modify piping.

Worn vanes Replace.

Pump without vapor return Without vapor equalization, a pump can remove only about 3% of the truck

tank capacity per minute without severe cavitation and capacity loss.

Worn sideplates Reverse or replace sideplates. Check universal drive assembly to make

sure angularity is within limits, yokes are parallel and slip-joint is greased.

Check bearings.

Vanes sticking Remove vanes and clean out foreign matter (check strainer). Replace

vanes if swollen.

Pump runs but no

flow

Valve closed Check valves. Make sure internal tank excess flow valve is open! Refer to

manufacturer’s instructions.

Excess flow valve slugged Stop pump until valve opens. If problem continues, slow pump down or

install a new or larger excess flow valve.

Broken shaft Disassemble and inspect pump. Repair if necessary.

Defective meter Service meter.

Pump will not turn

or is locked up

Foreign matter in pump Clean out the pump and check strainer in suction line

Vanes broken Clean out pump carefully and replace vanes. Has pump been operated dry?

Then, check for damage to cam and rotor shaft assembly.

Bearing seized Replace pump bearings. Grease monthly. Use ball bearing grease

manufactured for intended service.

Moisture frozen in pump Let thaw and break loose carefully. Add alcohol to tank (on LP-Gas). Check

with product supplier about the possibility of water in the gas.

Will not build

pressure

Poor suction conditions Clean inlet strainer. Increase pipe size.

External bypass valve set

too low

Set valve for higher pressure—see instructions.

Worn vanes and/or

sideplates

Disassemble, inspect and repair as necessary. Do not run pump dry!

Pump is noisy Cavitation from poor suction

conditions

As above.

Vanes sticking As above.

Bearings worn Replace if necessary and grease monthly.

Very high differential Check for restriction in discharge line. Delivery hose too small pressure

and too long. Slow down pump!

Check vapor release float assembly on meter and meter differential valve.

PTO shaft vibration Inspect and repair driveline component.

Pump leaks

around shaft

Seal or O-rings failed Inspect seal assembly and replace if necessary. Keep new seal very

clean when replacing seal. Recommend a light oil film on O-rings. Do not

run pump dry!

In diagnosing pump and system troubles, record the following data during product transfers:

1. Pressure at pump suction.

2. Pressure at pump discharge.

3. Pressure in truck tank.

4. Pressure in tank being filled.

5. Pipe size and length of suction and discharge lines.

6. Size and length of vapor equalizing line.

7. Pump speed if practical.

36

Loading...

Loading...