Principles of a Sliding-Vane Pump

Corken’s Coro-Vane

®

pumps are a special type of rotary

positive displacement pump, known as a sliding vane pump.

The sliding-vane pump has many of the positive

displacement advantages of the gear pump, plus the

ability to compensate for wear, and operate at a lower

noise level.

The sliding-vane pump consists of a rotor turning in

a cam (liner) machined eccentrically in relation to the

rotor; thereby displacing the liquid trapped between

the rotor, cam and vanes. Coro-Vane

®

pumps are made

with vanes produced from advanced polymers which

exhibit extremely low coefficients of friction. The vanes

self-adjust for wear and extends the pump life.

Exclusive Features of the

Coro-Vane

®

Pump

The pumping of volatile liquids is one of the most

difficult of all pumping jobs, so more attention must be

given to the design and manufacture of the pump and

to its installation and operation.

In addition to being especially suited for handling volatile

liquids, the Coro-Vane

®

pump has a number of features

to help make it more easily operated and maintained.

Coro-Vane

®

pumps are manufactured in six models:

the Models D51 and F51 small stationary and the

Models 521, 1021, F1021 and F1521 stationary pumps.

The Models F1021 and F1521 have ANSI flanged

connections. All six models have been registered and

listed by the UNDERWRITERS’ LABORATORIES, INC.

for use in the handling of LP-Gas and Ammonia.

The CASE AND HEADS are made of ductile iron for

extra strength and toughness.

The VANES are manufactured of advanced polymers

to provide excellent life and quiet operation. After long

service, the vanes are simply and inexpensively replaced.

Both the CAM and the SIDEPLATES are easily replaced

should the need arise.

The MECHANICAL SEAL is designed for longer life

under greater loads and may be inspected or replaced

without disturbing the piping of the pump. No special

tools are needed.

BEARINGS are heavy-duty roller type for long bearing life.

PRESSURE GAUGE connections, 1/4" pipe thread,

are provided.

The PUMP NOZZLES on Models 521 and 1021 are

equipped with flanges to simplify piping. It is not

necessary to provide unions in the piping system near

the pump because the flanges serve this purpose.

The RELIEF VALVE is built-in as part of the pump on

models 521 and 1021 and is adjustable under pressure.

NOTE: EVEN WITH THIS INTERNAL SAFETY VALVE,

AN EXTERNAL BYPASS VALVE MUST BE INSTALLED.

Chapter 1—Installation Procedures

1.1 Location

The installation of the Coro-Vane

®

pump is simple;

however, in order for the pump to deliver optimum

performance, the principles discussed in this book

should be followed. The piping details in figure 1.2

illustrate methods proved by hundreds of installations.

Your own needs may require slight variations, but every

effort should be made to follow the recommendations

identified in this manual.

No pump can discharge more liquid than it receives, so

the pump location and the inlet piping must be given

careful attention. If the inlet piping is unable to supply

the demand of the pump, you may expect trouble. The

inlet sizes shown in figure 1.2 are the smallest piping

size you can use with success.

For the transfer of flammable liquids like LPG, the pump

must be installed according to the applicable local

safety and health regulations. The installer and/or the

user must take into account the following:

• The pump must be located as near the storage tank as

possible. The complete inlet line, including the vertical

line from the tank must not exceed twelve feet (3.7 m)

in length.

• The bottom of the tank must be no less than two feet

(0.6 m) above the pump inlet nozzle, with four feet

(1.2m) considered standard.

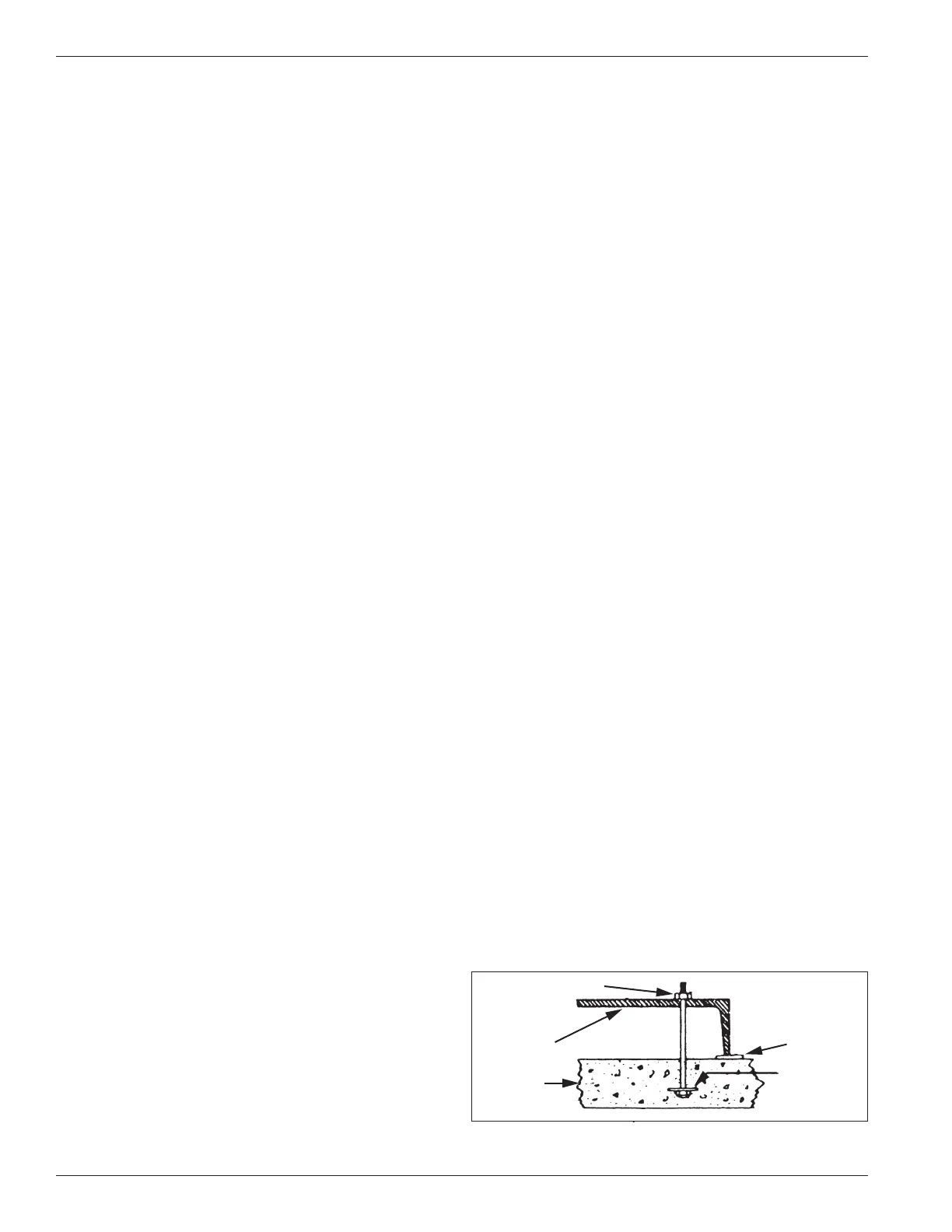

• The foundation for the pump is important. The foundation

must be firm, level and preferably made of concrete. The

suggestions in figure 1.1 should be observed.

Concrete

Large washer

Metal shim

Pump base

1/2" x 8" anchor bolt

Fig ur e 1.1

4

Loading...

Loading...