Drying Methods

In the following the basics for the different drying methods that can be applied with the CTR A ES and

applicable supplemental products from the Corroventa product portfolio are presented. The

descriptions are merely overviews. Thus, if in doubt on how to proceed with given situation, consult

experienced drying expert.

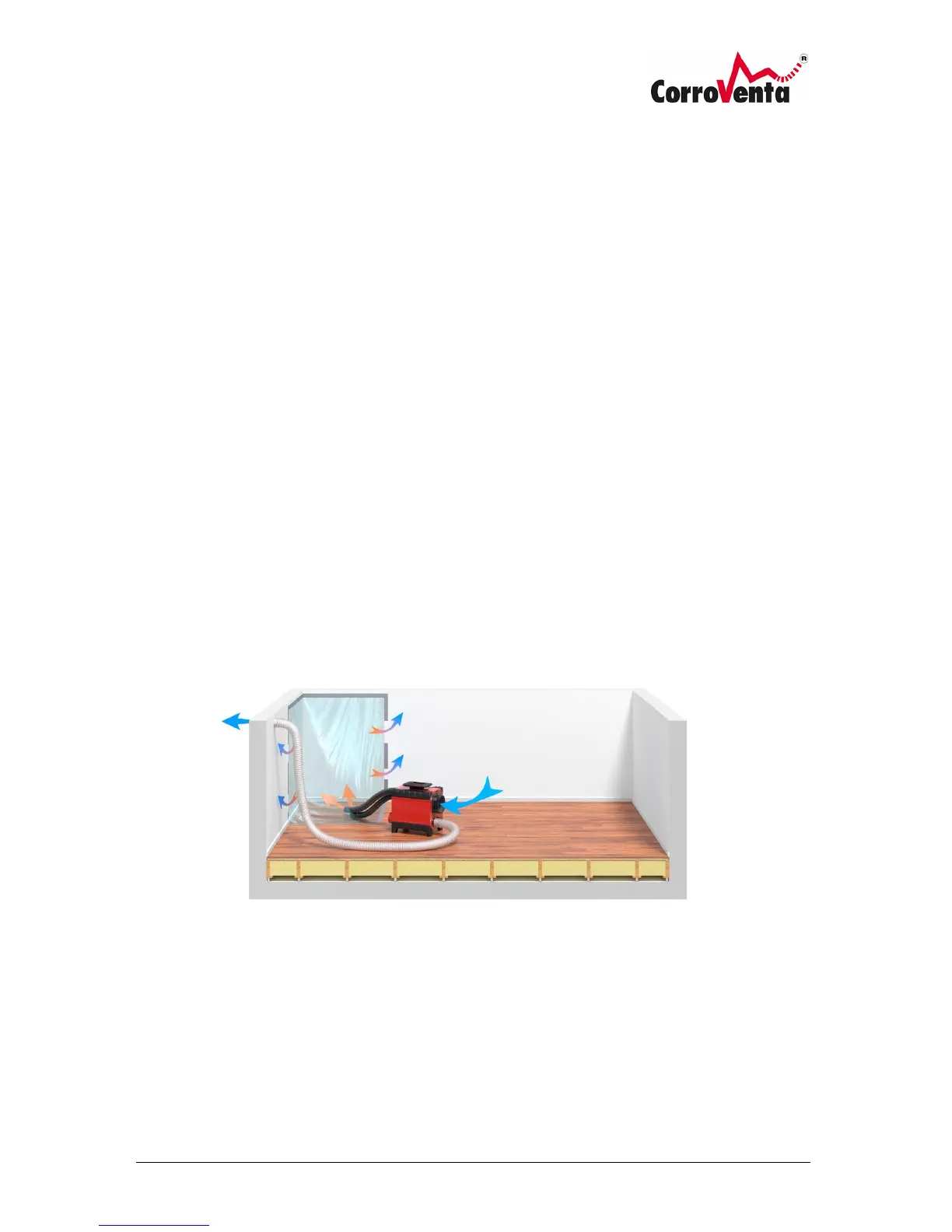

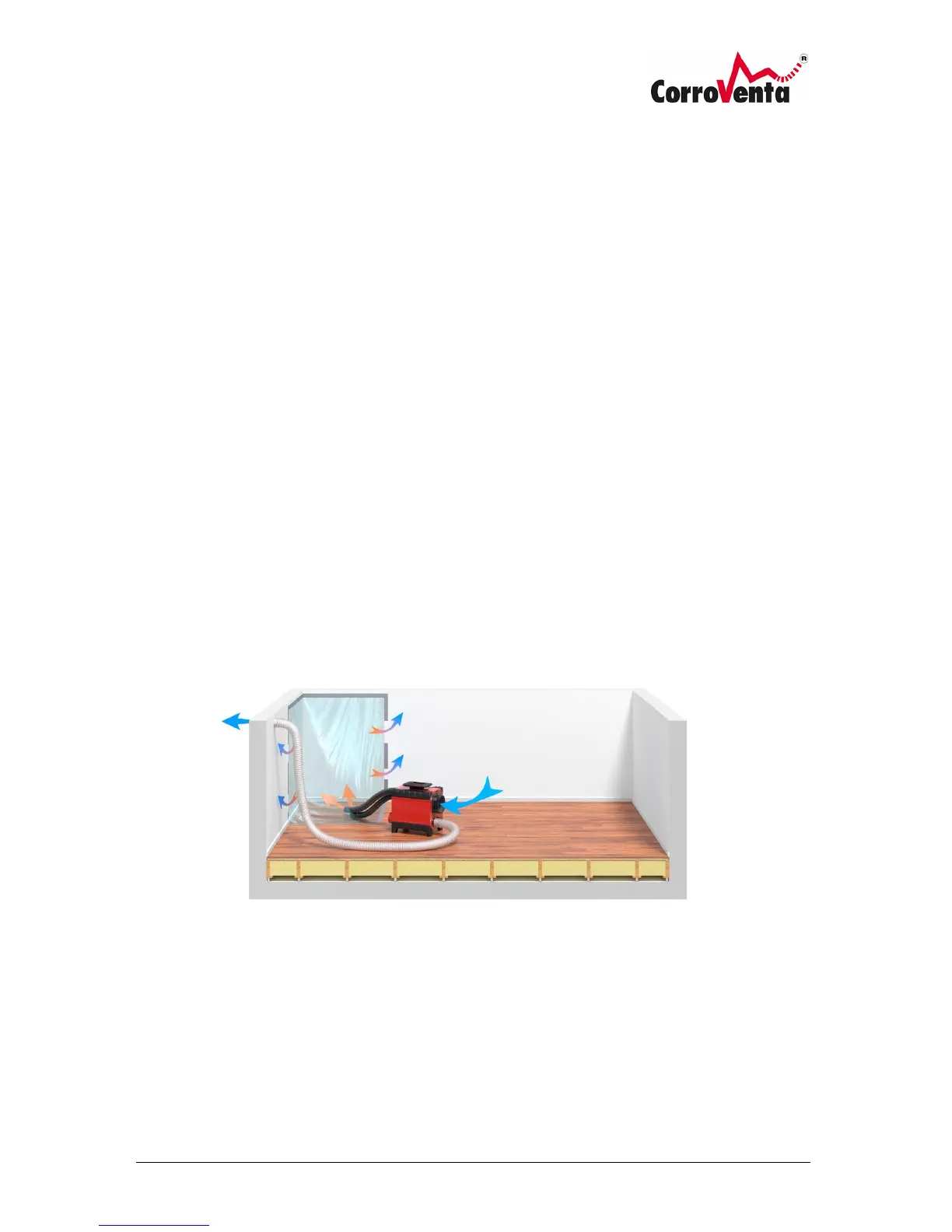

General drying, ambient air

An adsorption dehumidifier like the CTR A ES produces such dry air that a recirculation air flow rate

of between one and two times per hour is sufficient, to be compared with three to four times which

is suitable for a condensation dehumidifier. In other words, the CTR A ES which produces

approximately 300 m

3

of dry air per hour has capacity enough for a room of at least 50 – 60 m

2

and a

ceiling height of 2.5 meters.

As for all drying, regardless of type or model of machine used, it is important that the room or space

to be dried is well sealed in order for the process to be as energy efficient and quick as possible.

Windows and doors shall be shut and in absence of such delimiters, plastic foils or other temporary

sealing should be used.

If the damage is limited and local, it is preferably sealed with plastic foil and a hose then used to lead

the dry air in under the foil. By the edges of the foil small openings are left to let the air through and

create circulation. This method makes the process go faster and thus consume less energy.

Loading...

Loading...