The desiccant used in the CTR A ES is silica gel which can be regenerated an almost infinite number

of times. Silica gel is a crystal with enormous amounts of microscopic pores which makes its total

surface very large, a single gram has an active surface of 500 to 700m

2

. Silica gel is very potent and

can absorb water corresponding up to 40% of its own weight. It is not water soluble and can

therefore not be washed away nor dissipate into the passing air.

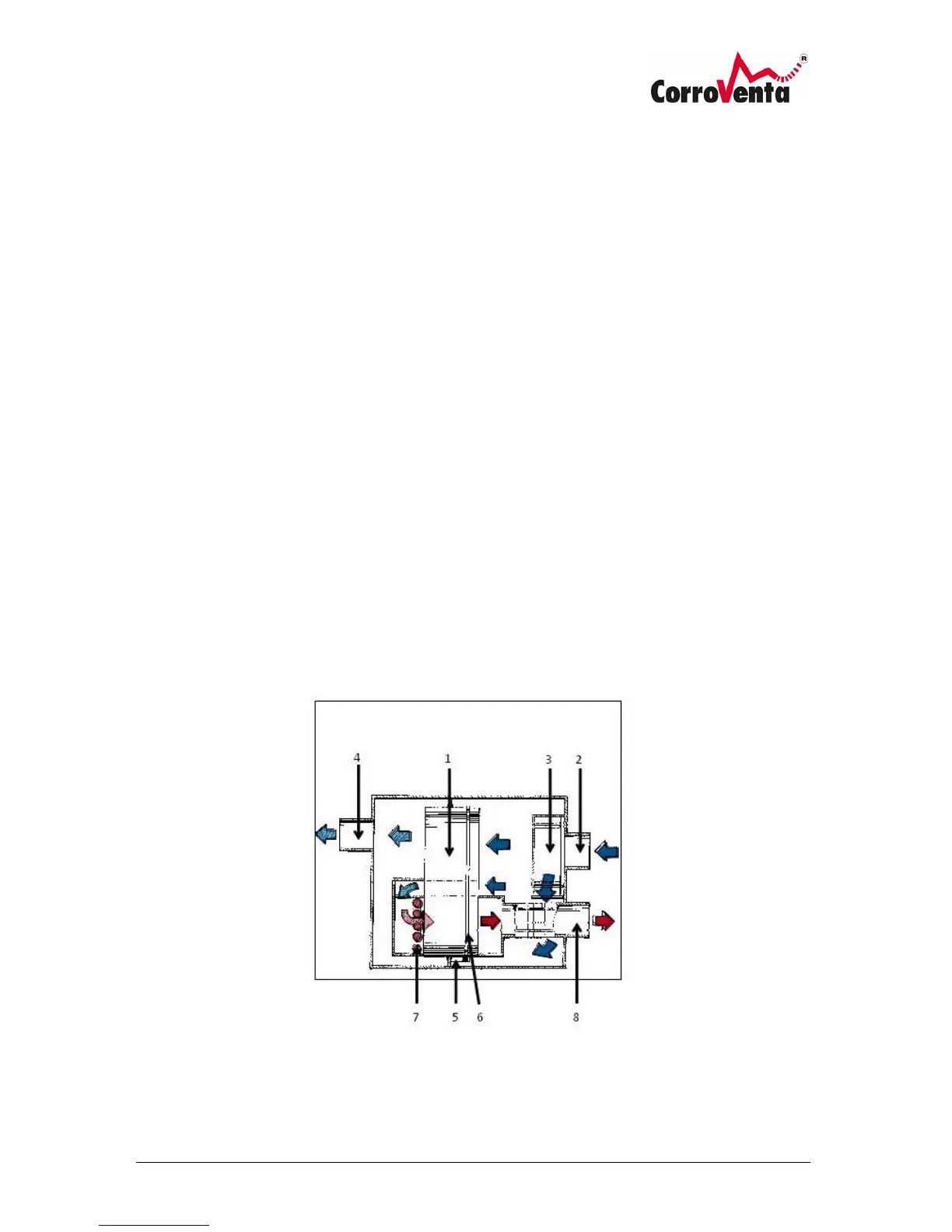

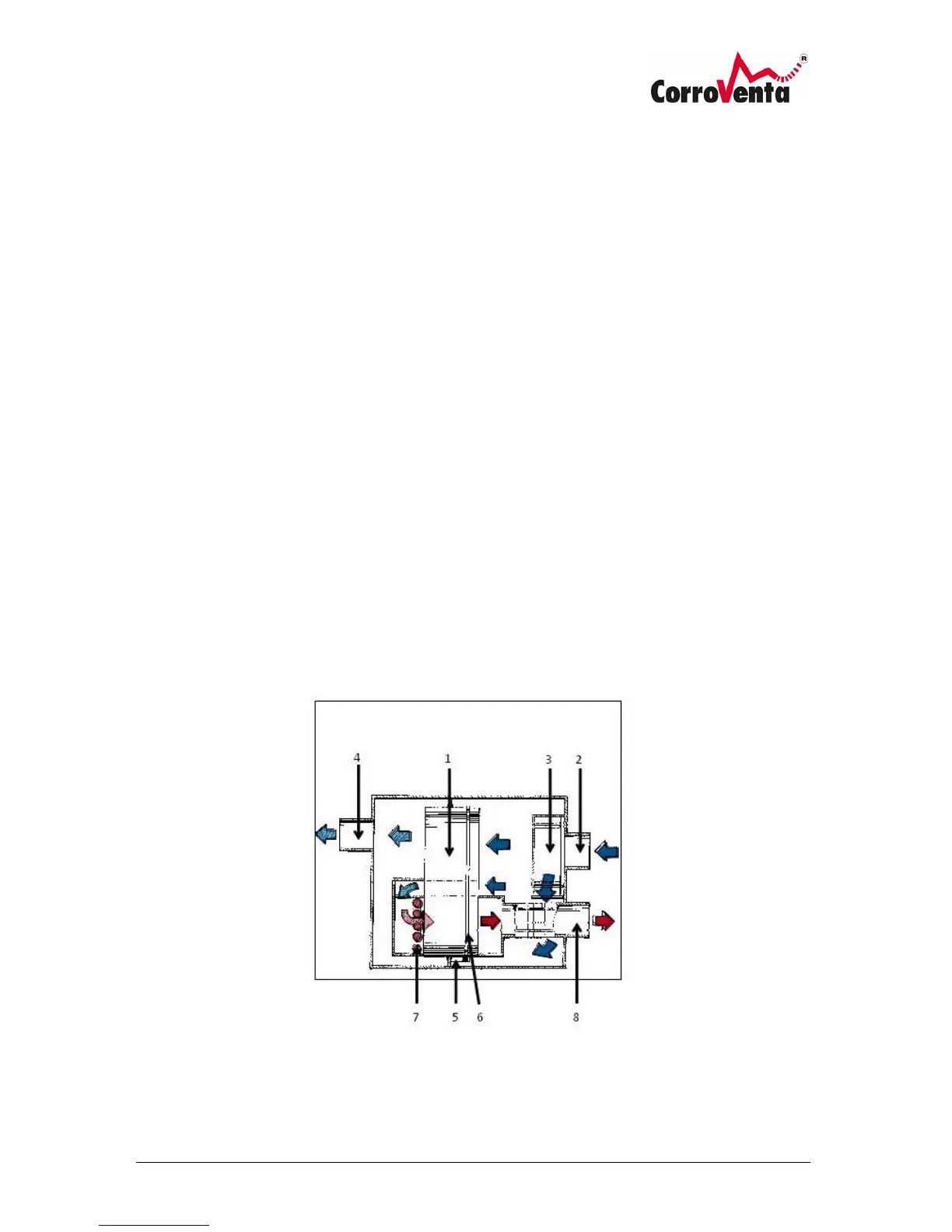

Dehumidification process

The desiccant is placed in a rotor (1). The air to be dried is drawn through the inlet (2) by a process

air fan (3).

The air passes a filter and then the rotor where after the dried air passes through the dry air outlet

(4) and into the environment to be dried. The rotor has air channels parallel to its axis and is made

from a highly potent desiccant, silica gel, fixed in a ceramic structure. The air channels in the rotor

provide a laminar air flow with a low pressure drop.

The rotor is rotated by an electric motor (5) and a belt (6). The moisture that is adsorbed is

removed by a small volume of process air that is heated (7) where after it is passed through a

section of the rotor, thus regenerating it as well as cleaning it through the counter flow principle.

The wet air is evacuated through the wet air outlet (8).

Loading...

Loading...