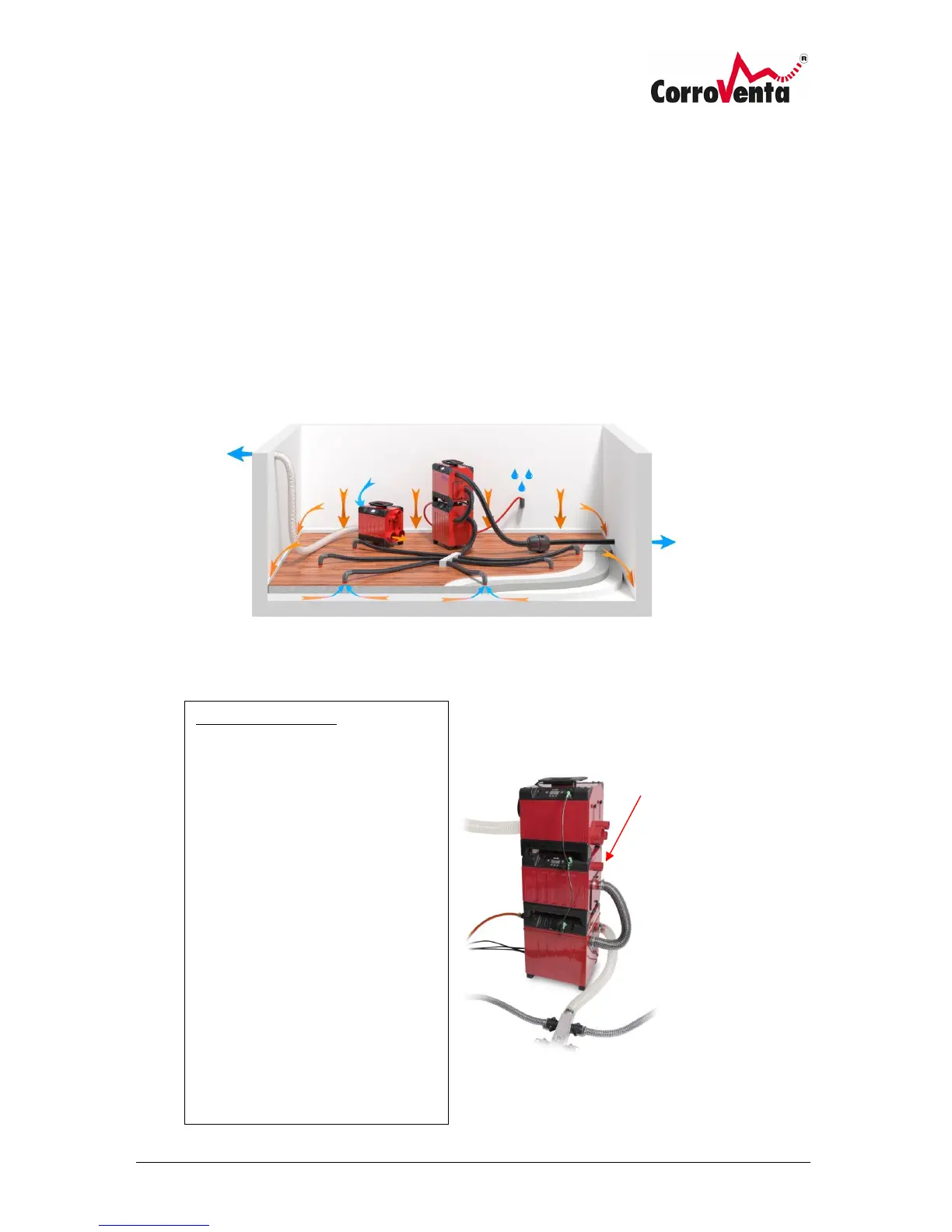

Suction Drying

For suction drying of layered constructions such as floating floors, the CTR A ES is used with one or

more turbines from the Corroventa product portfolio, in accordance with the schematic sketch

below. The turbine or turbines are connected to hoses with filters and water separators through

which they draw air from layered construction and then evacuate this, normally outdoors. The

dehumidifier is placed in the room and its wet air hose installed to evacuate the wet air. The turbines

will this way draw dry air down into the layered construction through drilled holes or through the

gaps between the floor and the walls.

Note that, as mentioned above, a water separator must be used to avoid free water from being

sucked into, and damaging, the turbine.

Suction drying. The dryer dries the ambient air and turbines draws and evacuates air from the

construction. The resulting underpressure in the construction draws dry air into it.

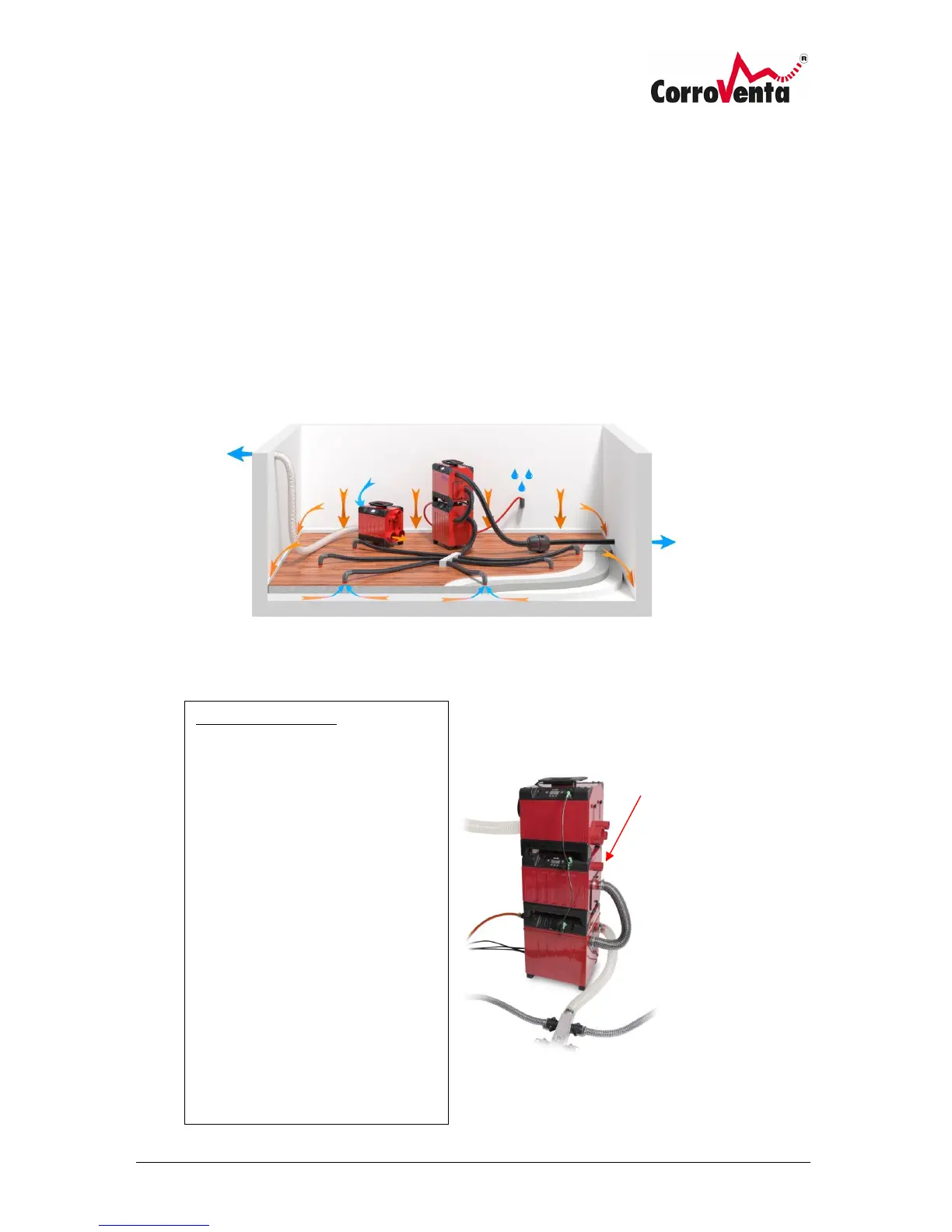

Suction drying setup:

At the top, CTR A4 ES drying

ambient air.

In the center, a CTR T4 ES turbine

pulling air from the water separator.

The turbine outlet shall be provided

a hose leading to where the humid

air from the construction can be

released. The turbine is powered

through the water separator power

outlet.

At the bottom, a WS4 ES water

separator connected to hose system

with suitable number of distributed

suction points so as to ensure air

movement beneath the entire floor.

Use hose to release

the humid air from

the turbine outside

the room.

Loading...

Loading...