COUNTERFLOW DIRECT VENT GAS WALL HEATER 23

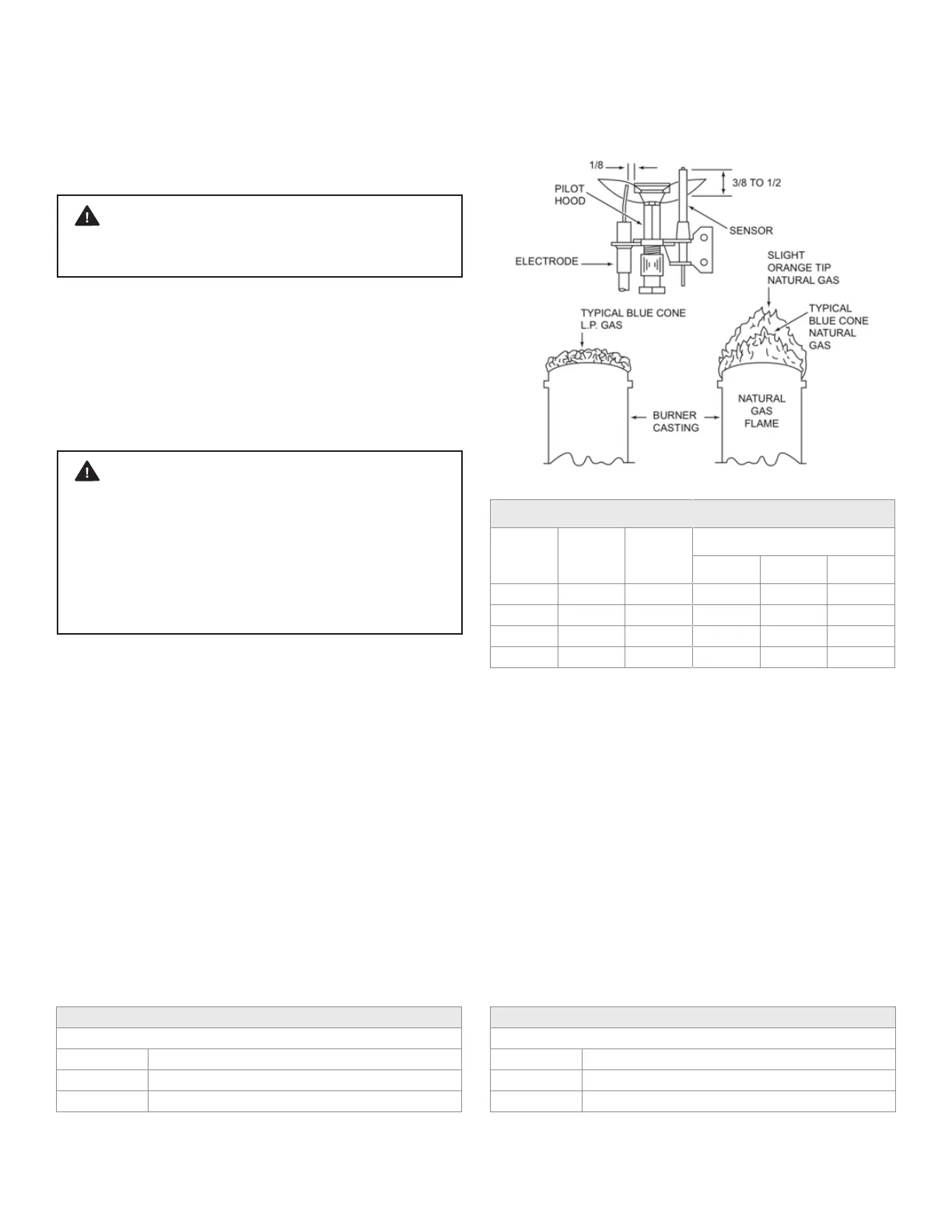

FURNACE TECHNICAL INFORMATION

MODEL

NUMBER

GAS TPE

INPUT**

RATING

BTU/hr.

MAIN BURNER ORIFICE

DRILL DEC. QTY.

DVCF402D NATURAL 40,000 #32 .1160 1

DVCF401D PROPANE 40,000 #48 .0760 1

DVCF602D NATURAL 60,000 #38 .1010 2

DVCF601D PROPANE 60,000 N/A .0640 2

GAS CONVERSION KITS

NATURAL GAS TO PROPANE GAS

MODEL DESCRIPTION

7728 DVCF40XD

7732 DVCF60XD

GAS CONVERSION KITS

PROPANE NATURAL GAS

MODEL DESCRIPTION

7729 DVCF40XD

7733 DVCF60XD

BURNER CLEANING

Check burner. If cleaning is required, contact a qualified

service technician to clean and service burner.

WARNING: Danger of bodily injury or death.

Make sure electric power and gas supply are off before

removing panels or doors, etc.

CLEANING BURNER COMPARTMENT

Because cold air is attracted to the flame during furnace

operation, a build up of lint from bedding and dust, etc.,

in the burner area will occur each heating season. It is

necessary to clean this area regularly. Use a vacuum

cleaner with a narrow attachment to reach small areas. Be

careful in and around the pilot. A change in its adjustment

could be made if struck during cleaning.

WARNING: A BUILDUP OF ANY DUST, LINT

OR FOREIGN MATERIAL IN THE PRIMARY AIR

OPENING OF THE BURNER CAN INTERFERE WITH

THE PROPER AIR GAS MIXTURE AND GAN RESULT

IN A YELLOW FLAME WHICH CAN PRODUCE

CARBON MONOXIDE AND SOOT. THIS CONDITION,

IF ALLOWED TO DEVELOP, CAN LEAD TO BODILY

INJURY INCLUDING DEATH. IT IS IMPERATIVE THAT

THE BURNER(S) BE KEPT GLEAN.

Disconnect the gas line inside the cabinet.

Remove three screws from the front of the combustion

chamber bottom panel and drop the assembly down.

Clean inside the combustion chamber and the burner

with a shop type vacuum cleaner.

To remove burners remove screw from the end of the

burner and slide the burner out of its bracket (it may be

necessary to slightly spring the bracket).

Inspect the Burner Box gasket. Replace if damaged.

Replace burner assembly and control assembly by

reversing the above procedures.

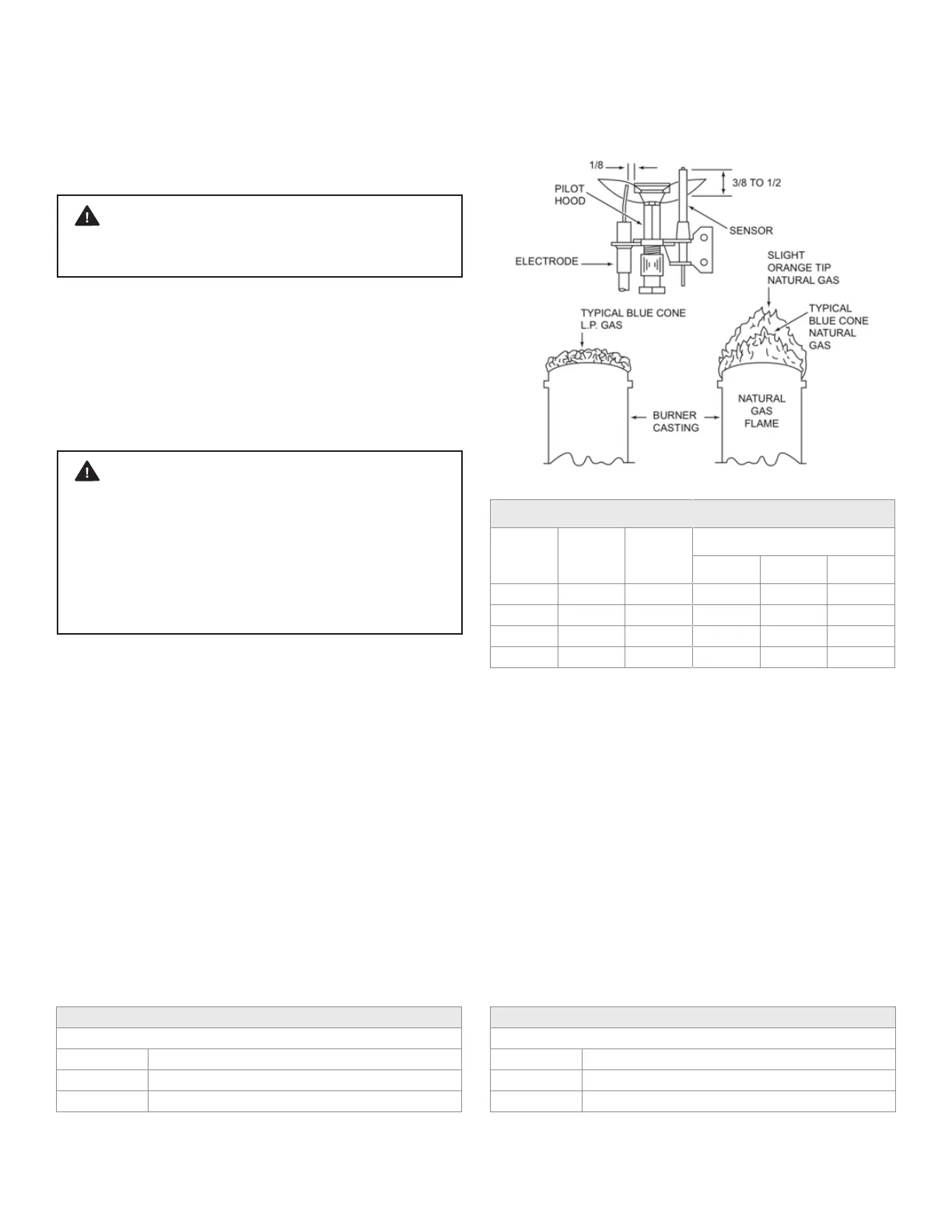

Check the spark gap. It must be carefully adjusted to

specifications, as illustrated (Figure 30), for the ignition

device to function properly.

FIGURE 30 - PILOT FLAME & SPARK GAP

The efficiency rating of these appliances is a product of

a thermal efficiency rating system determined under

continuous operating conditions and was determined

independently of any installed system.

**For elevations above 2,000 feet reduce ratings 4% for

each 1,000 feet above sea level.

**BTU/hr. = British Thermal Units per hour.

PROPANE

GAS

FLAME

Loading...

Loading...