10

Detailes:

Replacement of Chuck

The head spindle holding fixture is cylindrical. Loose three set

Screw/nut(A. Fig. 9)on the flange to remove the chuck

Replace new chuck and fix it by the same set screws and nuts.

Replacement of Chuck Jaw Fig.9

5The jaws are in two types – the internal jaws and the external

Jaws(Fig. 10). Please pay notice that the number of jaws fit with

the number inside the chucks groove. Do not mix them together

When you are going to mount them, please mount them in

Ascending order, and when taking them out, take them out in

descending order (3-2-1) one by one. After finished this

procedure, rotate the jaws to the smallest diameter and make

sure there fit is right. Fig. 10

Tool Set-up

Set correction and clamp the cutting tool into the tool-post.

The tool must be clamped firmly. When turning, the tool has

a tendency to bend under the cutting force generated during

the chip formation(Fig. 11). For best results, tool overhang

should be kept to a minimum of 3/8” or less.

Fig. 11

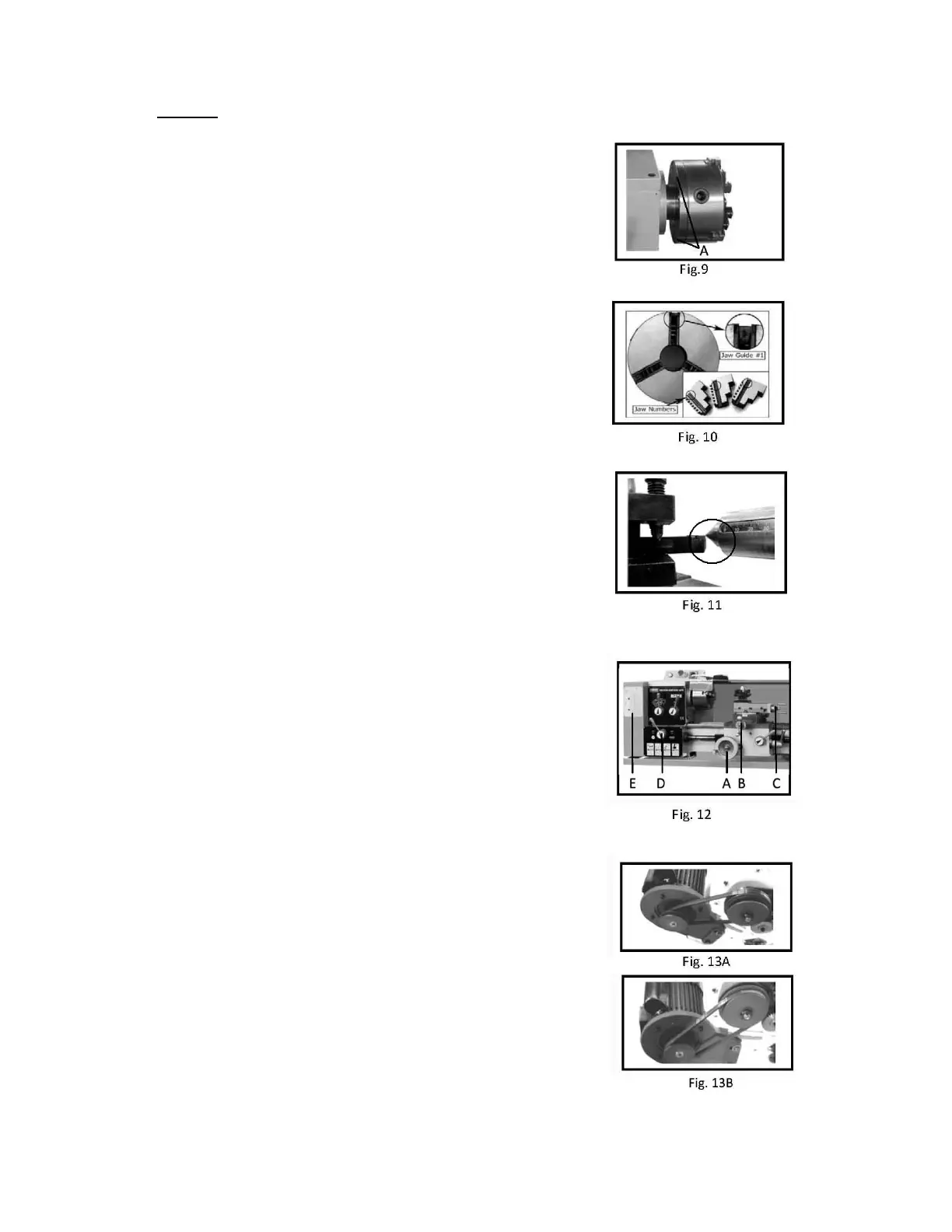

Manual Turning

Handwheel of Apron travel(A), cross travel(B) and top slide(C)

can be operated for longitudinal or cross feeding (Fig. 12)

Longitudinal Turing with Auto-feeding

1. Set the selector knob (D. Fig. 12) to select the feed

Direction and the feed speed

2. Use the table (E. Fig. 12)on the lathe for selecting the feed

speed or the thread. Adjust the change gear if the required Fig. 12

feed or thread cannot be obtained with the installed gear set

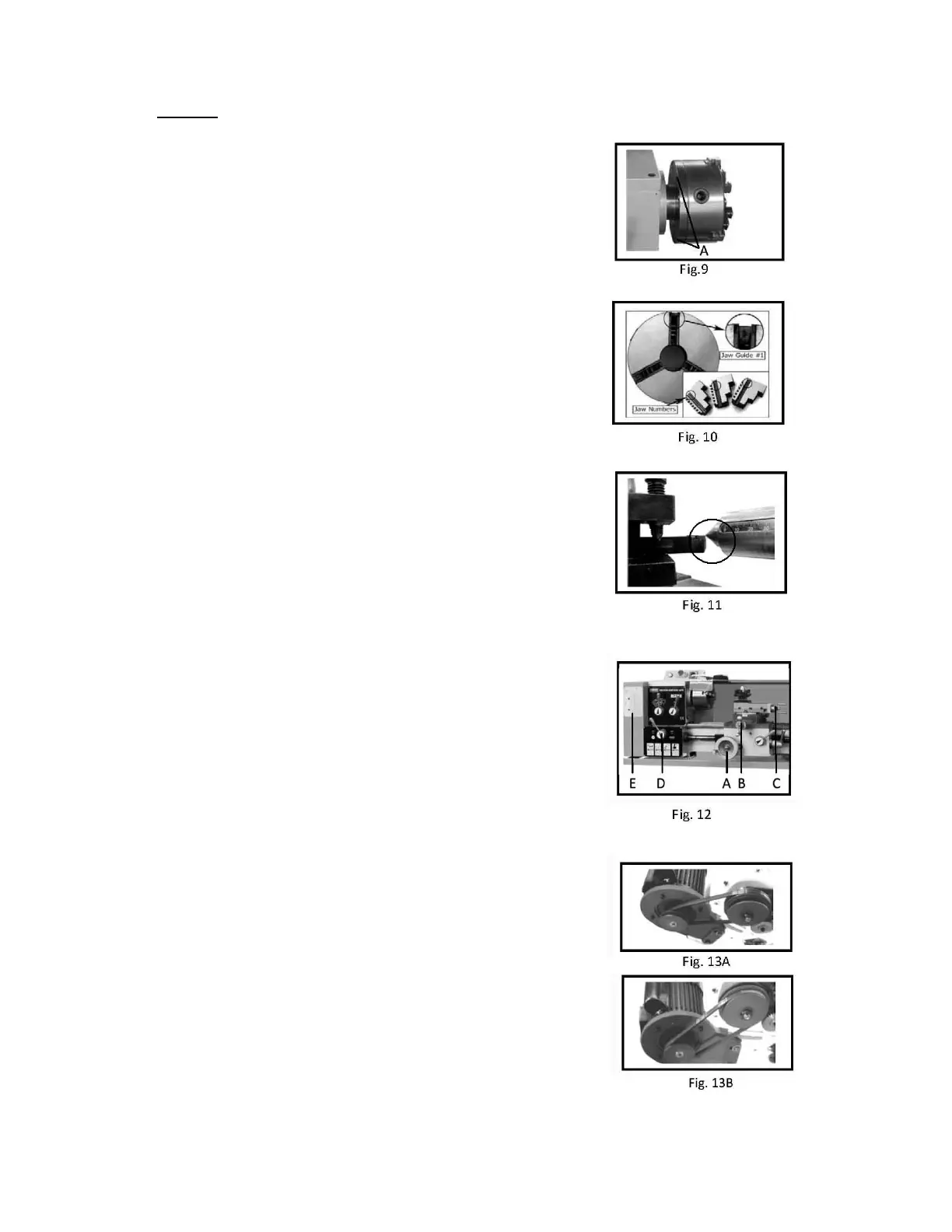

Change High/low Speed

Set the belt in inside groove of pulley (Fig. 13A) is running

at high speed.

Likewise, remove the belt from inside groove (Fig. 13A) Fig. 13A

to outside groove (Fig. 13B) is to be run with low speed,

which should be removed by manual or tools.

Loading...

Loading...