6

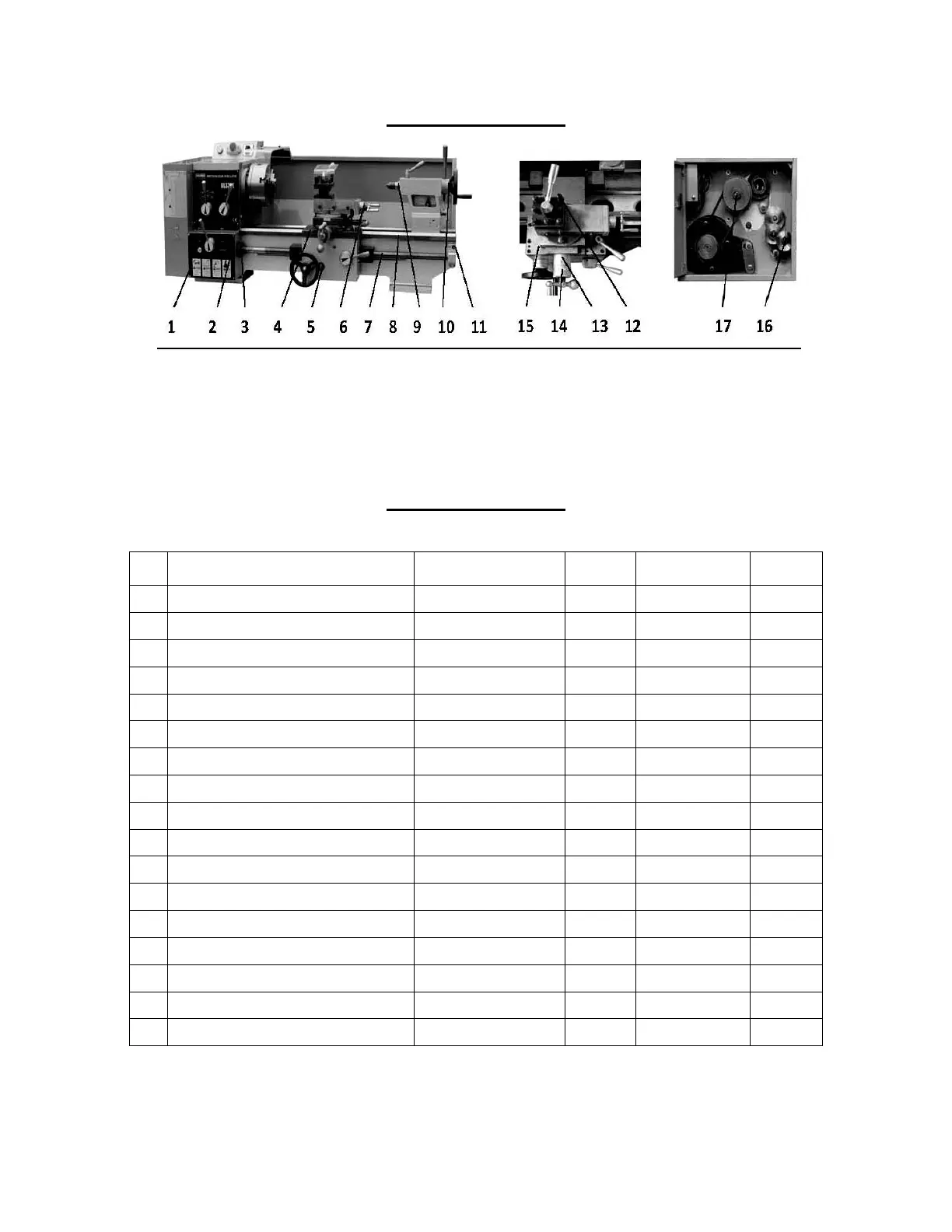

Lubrication Positions

Fig 4. Lubrication positions drawing.

Refer to the Lubrication chart on the following page in order to properly lubricate and maintain

your Lathe. Proper lubrication of any tools, especially Metal Lathes should not be ignored.

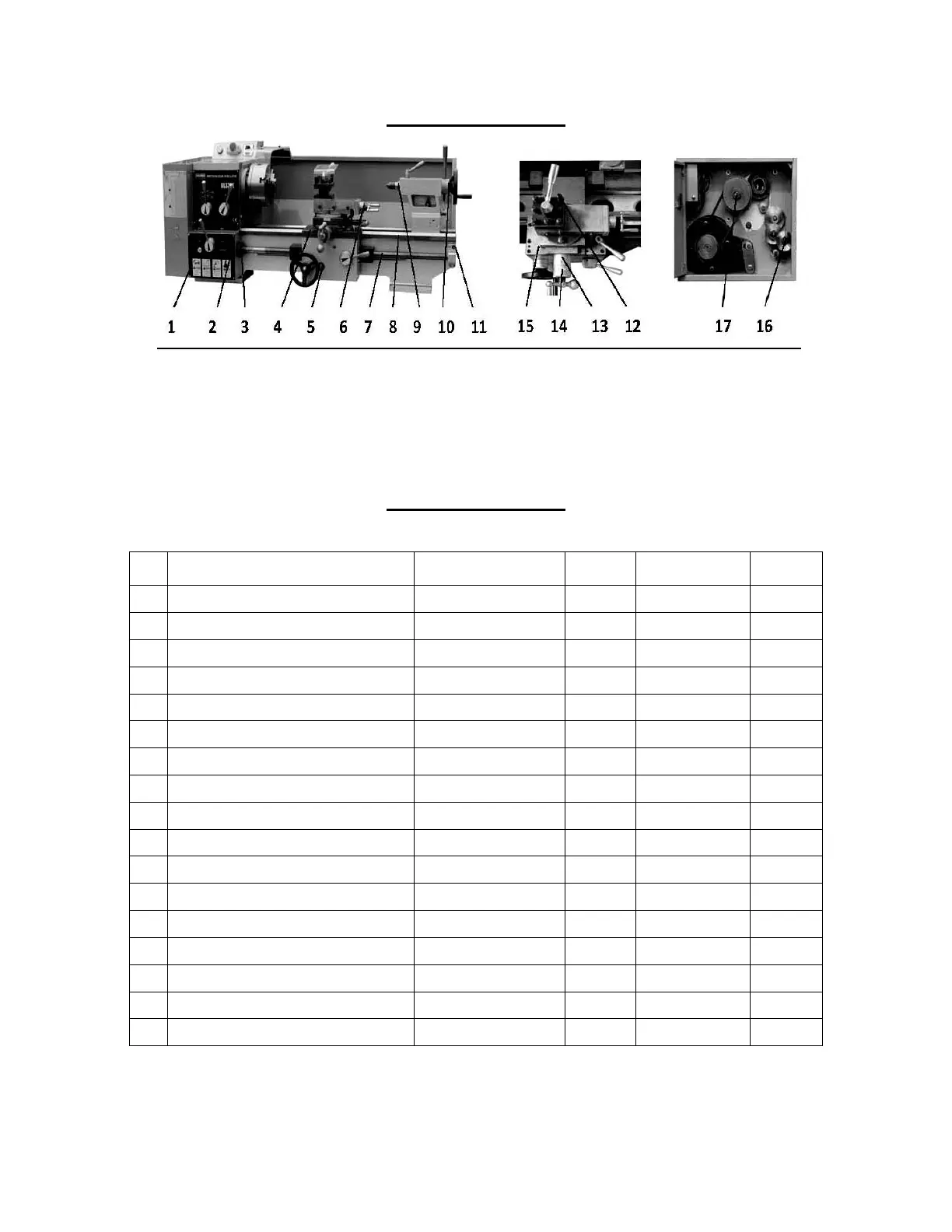

Lubrication Positions

No. LubricationPosition LocatedPart Located LubricationOil Period

1 Gears.bushbearing Lefttrestle Gun Machineoil 1S/Year

2 Spindlebearing Lathehead Greasing Grease 1S/Year

3 Thrustbullbearing Lefttrestle Greasing Grease 1S/Year

4 Slideway,leadscrew,guidesurface Apronparts Gun Machineoil 2S/Day

5 Gears,racks Apronparts Greasing Grease 1S/M

6 Toolpostleadscrew,guidesurface Toolcarriage Gun Machineoil 2S/Day

7 Longitudinalleadscrew Leadscrew Gun Machineoil 2S/Day

8 Lathebedguide Lathebed Gun Machineoil 2S/Day

9 Tailstocksleeve Tailstock Gun Machineoil 2S/Day

10 Tailstockleadscrewbushbearing Tailstock Gun Machineoil 2S/Day

11 Bearingpedestal Lathebed Gun Machineoil 2S/Day

12 Crossnutleadscrew Smallcarriage Gun Machineoil 2S/Day

13 Bearingbush Smallcarriage Gun Machineoil 2S/Day

14 Thrustbearing Leadscrewpedestal Greasing Grease 6S/Year

15 Tailstockleadscrewbushbearing Tailstock Gun Machineoil 2S/Day

16 Changegearshaft Compoundbox Gun Machineoil 2S/Day

17 Bearing Inputpulley Greasing Grease 1S/Day

Notes: 1. Recommend to fill 3# Ca grease 20# machine oil

2. The parts lubricated by grease should be cleaned and the machine oil in

feed

box should be changed and renewed up to the center line of the oil indicator regularly.

Loading...

Loading...