32

1-4 Check after operation:

1) Cleaning and collection of all tools:

All tools should be kept clean first then put back to original position (tool cabinet)

2) Proper position of tailstock, carriage, & tool holder:

Tailstock, carriage, & tool holder should be placed to proper position.

3) Clean-up of machine:

All of the oily matters, chips etc, on the machine should be removed completely and put a thin

lubricating oil on the sliding surface of machine to prevent the corrosion.

1. WEEKLY INSPECTION:

1) Lubricating system:

Clean-up the whole lubricating system and replenish with fresh lubricating oil.

2) Cooling system:

Clean-up the whole cooling system and replenish with new cooling oil.

3) Transmission system:

Check the damage of rubber V-belt and readjust the tensile strength of V-belt.

2. Trouble Shooting

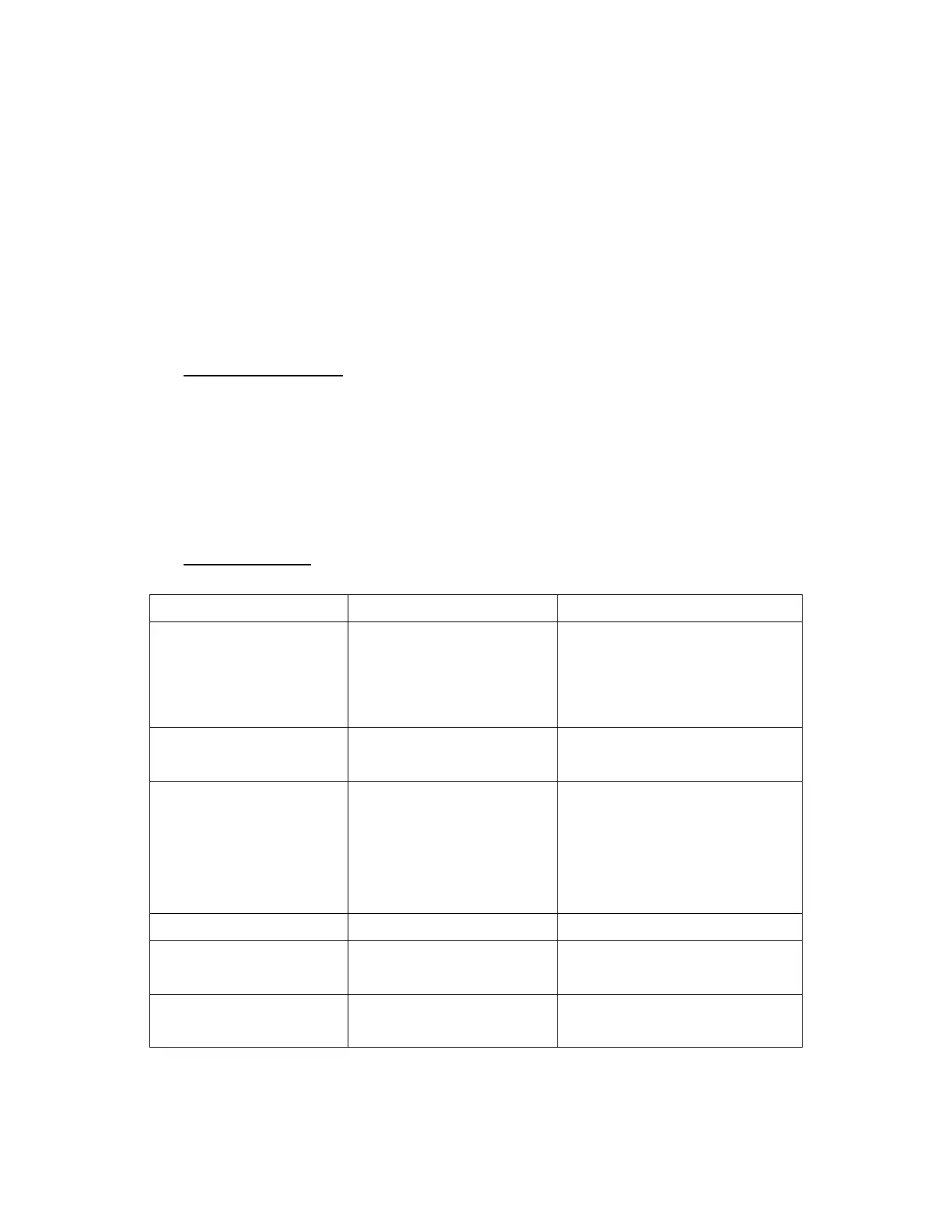

Problem Possible Cause Remedy

Too chatters Gibs too loose on table.

Unused feeds not locked

Tool not on center.

Improper tool shape.Tool dull

Readjust gibs.

Lock all axes but one moving

Center tool

Reshape, sharpen, replace tool

Depth of cut is not

consistent

Quill moving

Setup wrong

Lock quill

Make sure setup is parallel to table

Hole is off center or bit

wanders

Bit dull.

Bit not mounted correctly

Chuck loose in spindle.

Bearing loosen or worm.

Cutting too fast.

Use sharp bits

Remount tool

Remount chuck on spindle

Tighten or replace bearings

Reduce down speed

Bit turns erratically or stops Bit fed into work too fast Reduce down feed rate

Chuck is difficult to tighten

or loosen

Chuck sticking.

Debris in chuck

Apply lubricant

Clean chuck inside

Turn on machine and

nothing happen

Machine unplugged.

Loose electrical connections

Plug in machine

Tighten wiring connections

Loading...

Loading...