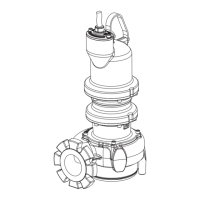

This document is an Installation and Operation Manual for BARNES Solids Handling Submersible Pumps, specifically for Explosion Proof, Class 1, Division 1, Groups C & D, T4 models.

Function Description

The BARNES Solids Handling Submersible Pumps are self-contained pumping units designed for submerged continuous duty in sumps, lift stations, or basins. They are suitable for pumping sewage, effluent, wastewater, or other non-explosive or non-corrosive liquids not exceeding 104°F (40°C). The pumps are engineered for efficient performance and are built with high-quality components for demanding applications.

Important Technical Specifications

Pump Models and Configurations:

The manual covers various models, including:

- 4XSHM (Monovane Pumps): 75HP, 1750RPM

- 4XSHD (Dual Vane Pumps): 75-100HP, 1750RPM

- 6XSHV (Vortex Pumps): 75-100HP, 1750RPM; 50-75HP, 1150RPM; 40HP, 870RPM

- 6XSHM (Monovane Pumps): 75-100HP, 1750RPM

- 6XSHD (Dual Vane Pumps): 75-100HP, 1750RPM

- 8XSHVV (Vortex Pumps): 50-100HP, 1150RPM; 40-50HP, 870RPM

- 8XSHDA (Dual Vane Pumps): 50-60HP, 1150RPM

- 8XSHDU (Dual Vane Pumps): 75HP, 1750RPM

- 8XSHTM (Tri Vane Pumps): 75-150HP, 1750RPM; 50-100HP, 1150RPM; 40-50HP, 870RPM

- 10XSHD (Dual Vane Pumps): 50-100HP, 1150RPM; 40-50HP, 870RPM

Electrical Data (Examples from Charts A, B, C, D):

The manual provides detailed electrical data for various models, including:

- HP: Ranging from 40HP to 150HP.

- Voltage (VOLT): Typically 460V or 575V.

- Phase (PH): 3 Phase.

- Frequency (Hz): 60Hz.

- RPM (Nom): 870RPM, 1150RPM, 1750RPM.

- NEMA Start Code: G, E, H, F, D.

- Full Load Amps (AMPS): Varies significantly by model, HP, and voltage (e.g., 4XSHME75044 (75HP, 460V, 1750RPM) has 108.4 FLA; 8XSHTM150044 (150HP, 460V, 1750RPM) has 199.4 FLA).

- Service Factor Amps (SERVICE FACTOR AMPS): Full Load Amps multiplied by service factor (typically 1.15 or 1.0).

- Locked Rotor Amps (LOCKED ROTOR AMPS): Varies by model (e.g., 4XSHME75044 has 578.0 LRA; 8XSHTM150044 has 840.0 LRA).

- Cord P/N A: Specific part numbers for power cords (e.g., 138319A, 138318, 138320).

- Cord Size: (e.g., 2/4-18/4, 6/4-18/4, 1/0/4-18/4, 8/4-18/4).

- Cord O.D.: (e.g., 1.47 ± .03, 1.14 ± .03, 1.72 ± .03, 1.12 ± .02).

- Winding Resistance (MAIN - START): Measured in OHMS @ 25°C (Between Lines) at motor leads, with a tolerance of ± 7.5%.

- Moisture and Temperature Sensors: Sensor leads are integral to the power cord.

- Pump Rating: Rated for operation at ± 10% voltage at motor.

Submergence Levels:

Recommended continuous duty and minimum submergence levels are provided based on discharge size:

- 4" Discharge: 44.45" (continuous), 16.86" (minimum)

- 6" Discharge: 45.79" (continuous), 18.17" (minimum)

- 8" Discharge: 46.04" (continuous), 18.42" (minimum)

- 10" Discharge: 45.17" (continuous), 17.55" (minimum)

The outer shaft seal must be in liquid when the motor is operated, whether submerged or in air.

Impeller Data:

Detailed tables for "E", "I", "J", "L", "M", "T", "V", "U", "W", and "X" impellers include:

- Trim Dia. mm (in): Various diameters from 190mm (7.48in) to 455mm (17.91in).

- Ductile Iron Part No.: Specific part numbers for ductile iron impellers.

- Nihard Part No.: Specific part numbers for Nihard impellers.

Impeller kits, wear rings, and attachment hardware are also listed.

Volute Pilot Diameter:

A table lists volute sizes, volute part numbers, volute kit part numbers, wear ring part numbers, and O-ring part numbers for various models.

Leg Kits:

Leg kits are available, including 3 legs (painted) and attachment hardware. Leg height varies by model (e.g., 3.15 inches for 3XSHVC, 10.75 inches for 10XSHDX).

Usage Features

- Explosion Proof Design: Certified for Class 1, Division 1, Groups C & D, T4 environments, ensuring safe operation in hazardous locations.

- Continuous Duty: Designed for continuous operation when submerged, with a 15-minute duty rating in air at nameplate horsepower.

- Break Away Fitting (BAF) System: Barnes Pumps offers a BAF discharge system that allows for pump installation or removal without personnel entering the wet well.

- Level Control: Liquid level control systems are recommended, typically using a two-pump system with a high-level alarm.

- Electrical Connections: Detailed instructions for power and sensor lead connections, including specific wiring diagrams for 8 AWG, 6 AWG, 2 AWG, and 0 AWG / 18/5 - Dual Cord configurations.

- Overload Protection: Thermal sensors embedded in motor windings detect excessive heat and open the control circuit to turn off the pump, preventing damage. A manual momentary start switch is required to prevent automatic restarting.

- Moisture Detection: Moisture sensors in the seal chamber detect water intrusion, triggering an alarm or shutting down the pump.

- Storage Guidelines: Short-term (up to 6 months) and long-term (up to 24 months) storage instructions are provided to maintain pump integrity.

Maintenance Features

- Preventative Maintenance: Regular checks of oil level, seal integrity, and impeller clearance are crucial.

- Oil Changes: Recommended every 15,000 hours of operation or annually. Use BARNES Premium Grade oil.

- Seal Service: Detailed instructions for disassembling, inspecting, and reassembling both inner and outer shaft seals. Emphasizes handling seal parts with extreme care and keeping seal faces clean.

- Impeller and Volute Service: Procedures for removing, inspecting, and reinstalling the impeller and volute are provided.

- Troubleshooting Guide: A comprehensive table lists common problems, their causes, and corrective actions (e.g., pump will not run, pump hums but does not run, pump delivers insufficient capacity, pump cycles too frequently, pump shuts off and turns on independently, pump operates noisily or vibrates excessively).

- Replacement Parts: Instructions for ordering replacement parts, including pump model, serial number, part description, and quantity. Extensive parts lists are provided for various components and kits (Seal Kit, Hardware Kit, Volute Kit, Impeller Attachment Kit, Cord Assembly, Removeable Cord Attachment Kit, Leg Kit).

- Returned Goods Policy: Requires a "Returned Goods Authorization" and emphasizes that products must be cleaned, sanitized, or decontaminated before shipment.

Loading...

Loading...