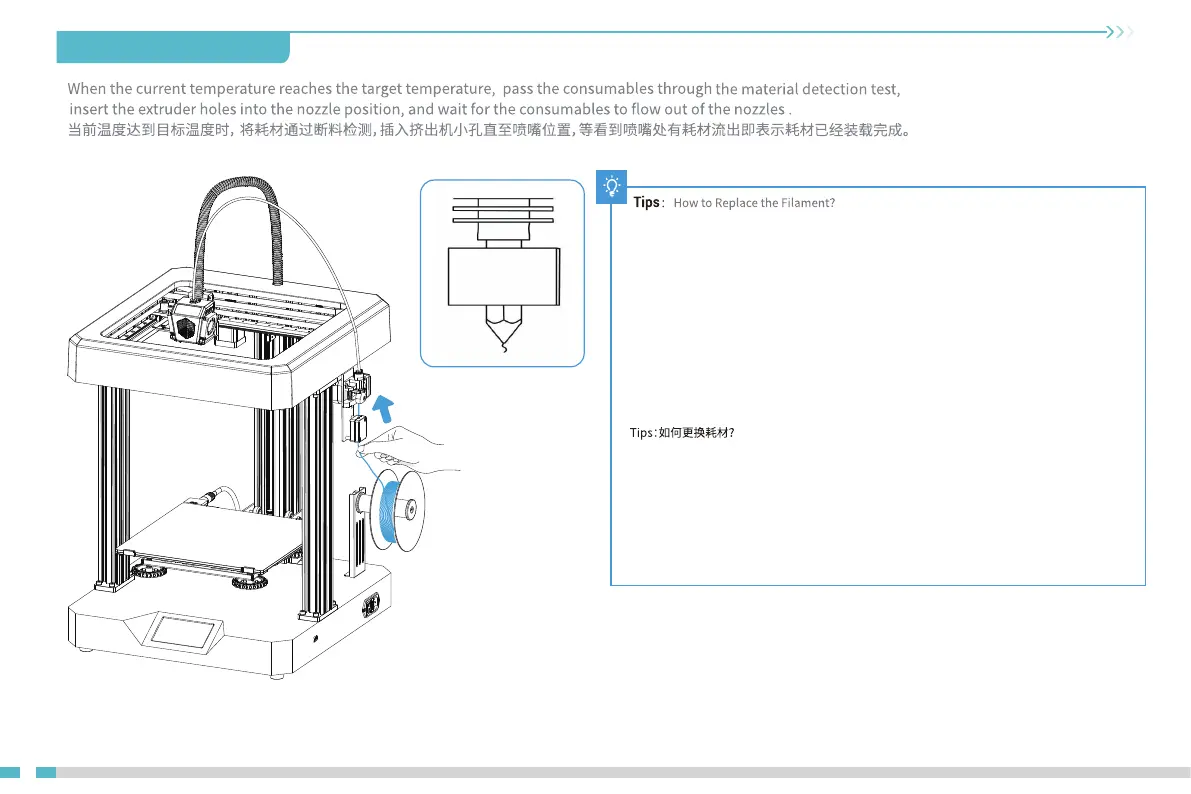

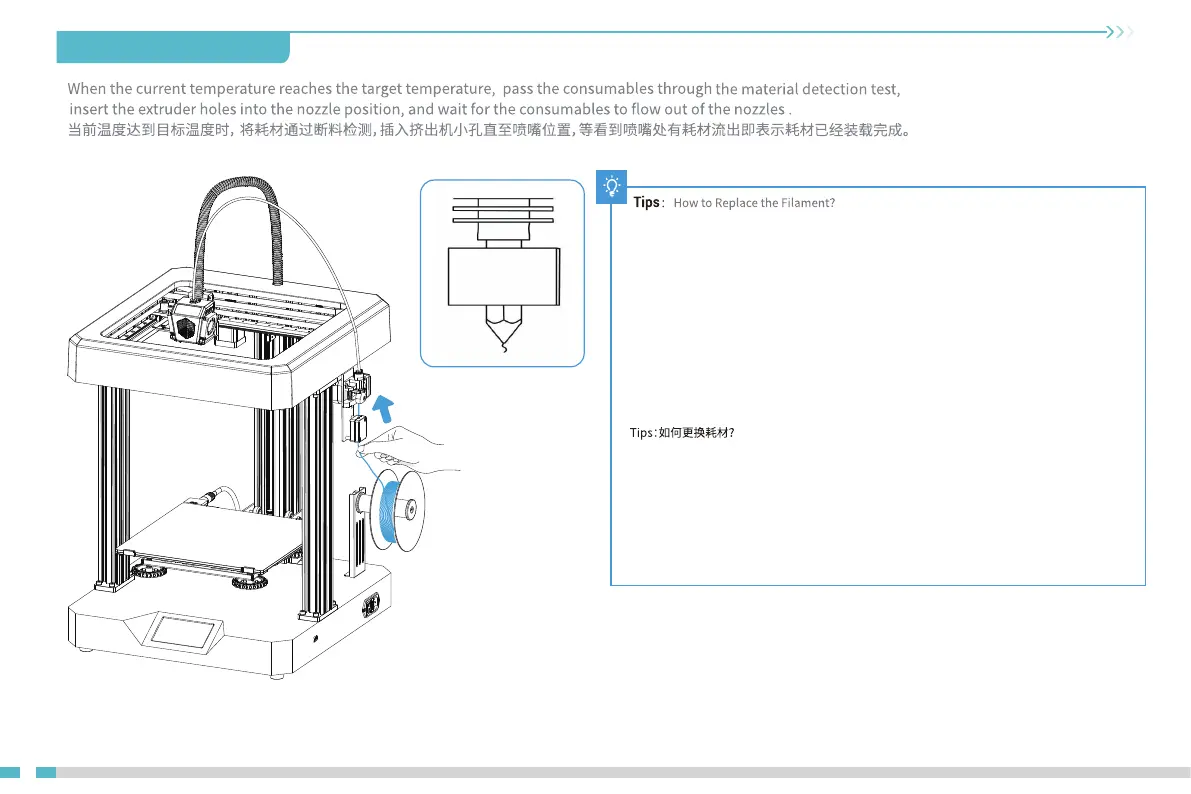

13. Load Filament 装料

21

方法1:

将新耗材插入断料检测内,指示灯亮,点击显示屏中的断料续打,将喷嘴温度设置到200℃,

然后将断料检测内的上批剩余的耗材从挤出机下方取出,温度升高后拉出剩余耗材。按压挤

出夹,将通过断料检测的耗材送入喷嘴为止。

方法2:

将新耗材插入断料检测内,指示灯亮,点击显示屏中的断料续打,开始续打后用手拿着耗材,

将其随着打印顺过挤出机。(该方法有存在由于耗材弯曲等原因,不能正常送入铁氟龙管内,

造成续打连不上风险)

Method 1:

Insert the new filament into filament runout detection module, the indicator

light is on. Click the "Resume after filament runout" in the display, and set the

nozzle temperature to 200℃. Take out the remaining filament in the filament

runout detection module from the lower part of the extruder after the

temperature rises. Push the extruding clamp until the filament is sent into the

nozzle through the filament runout detection module.

Method 2:

Insert the new filament into filament runout detection module, the indicator

light is on, then click the "Resume after filament runout" in the display. When it

starts to print, hold the filament and allow it to go through the extruder. (The

filament may not be properly fed into the Teflon tube due to bending or other

reasons, resulting in failure of resumption).

Loading...

Loading...