55

H. Assembly of Centrotherm Innoue Vent Systems

1. ThisboilerhasbeenapprovedforusewiththeCentrothermInnouesinglewallpolypropyleneventsystemtobe

provided by the installer.

2. Assemble the vent system, starting at the boiler:

a. Theventadaptorhastwodifferentinsidediameters.Thesmaller,lower,insidediameteraccepts3”nominalInnoue

(Figure 7.27). A locking ring in the adaptor prevents the vent pipe from coming out of the adaptor once it is inserted.

Lubricatetheuppergasketintheventadaptorwithwaterandinserttherstpieceof3”Innoueintotheadaptor

until it bottoms out.

b. If2”Innoueistobeusedfortheventsystem,reducetherstpieceof3”InnoueinstalledinStep(a)to2”using

Centrotherm#ISRD0302.Otherwiseassemblethenextpieceof3”Innoue.

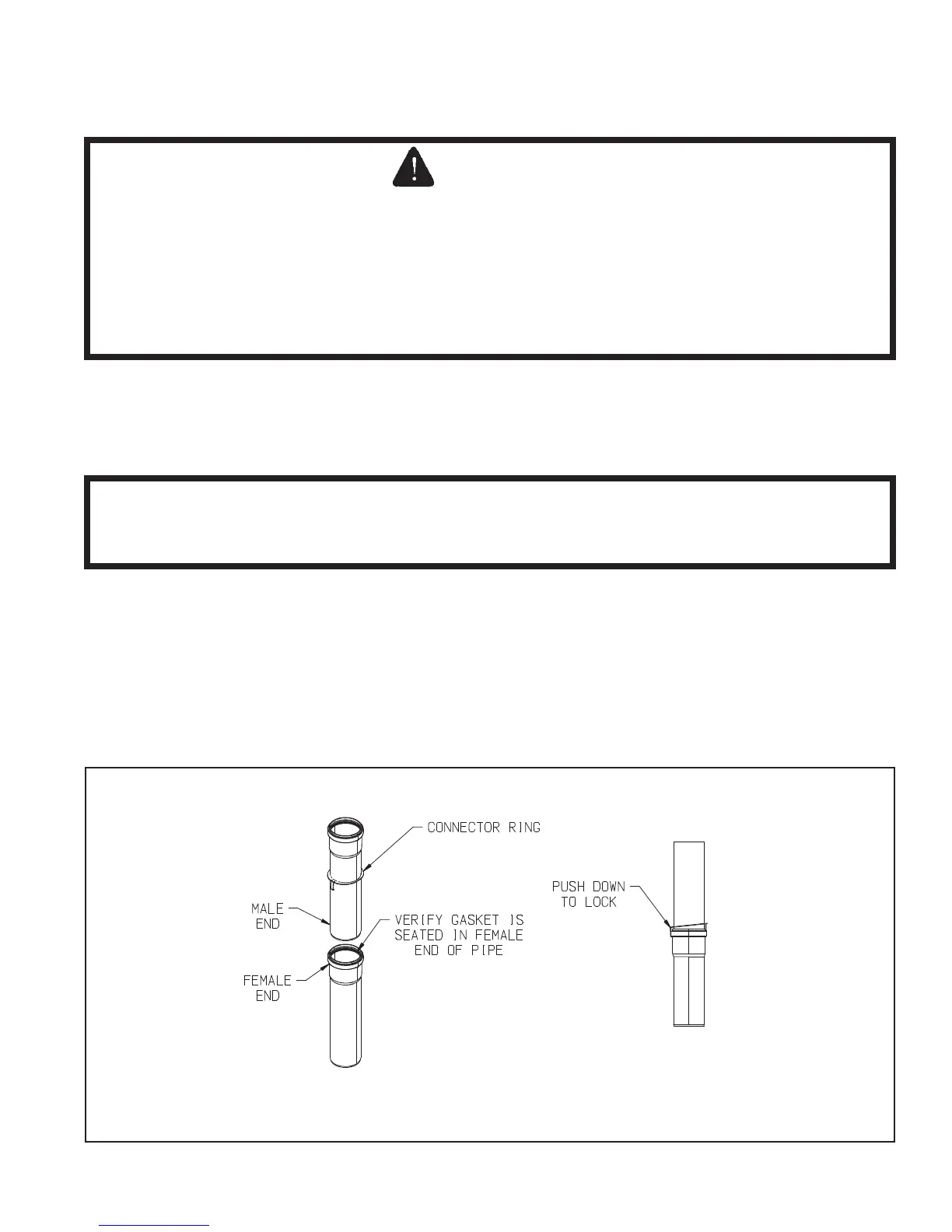

c. For each joint, verify that the gasket is evenly seated in the bell (female) end of the pipe. Lubricate this gasket with

Centrocerin # IACE50. Slide a connector ring over the male end of the pipe to be joined as shown in Figure 7.44.

Push the male end of the next section of pipe into the bell until it bottoms out, then back out 1/4” to provide room

forthermalexpansion.PushhookonconnectingringoverthebellendoftherstsectionofpipeasshowninFigure

7.44.

d. Assembletherestoftheventsystemperthemanufacturer’sinstallationinstructions,beingsuretopitchhorizontal

sections back towards the boiler 5/8”/ft.

e. Support each horizontal pipe section with a minimum of one wall strap each and at intervals not exceeding 39in.

FIGURE 7.44: INNOFLUE CONNECTOR RING INSTALLATION

Loading...

Loading...