65

B. Near Boiler Piping Design

ProperoperationofthisboilerrequiresthatthewaterowratethroughitremainwithinthelimitsshowninTable

9.1anytimetheboilerisring.Atowratesbelowtheminimumshown,theboiler’sowswitchand/ortemperature

riselimitfunctionmaypreventtheboilerfromring.Flowratesthroughtheboilerinexcessofthemaximumshownin

Table 9.1 can result in excessive noise or erosion damage to piping

There are two basic methods that can be used to pipe this boiler into the system. Method #1 (primary-secondary

piping) is always preferred. Additional information on hydronic system design can be found in the I=B=R Guide RHH

published by the Air-Conditioning, Heating and Refrigeration Institute (AHRI).

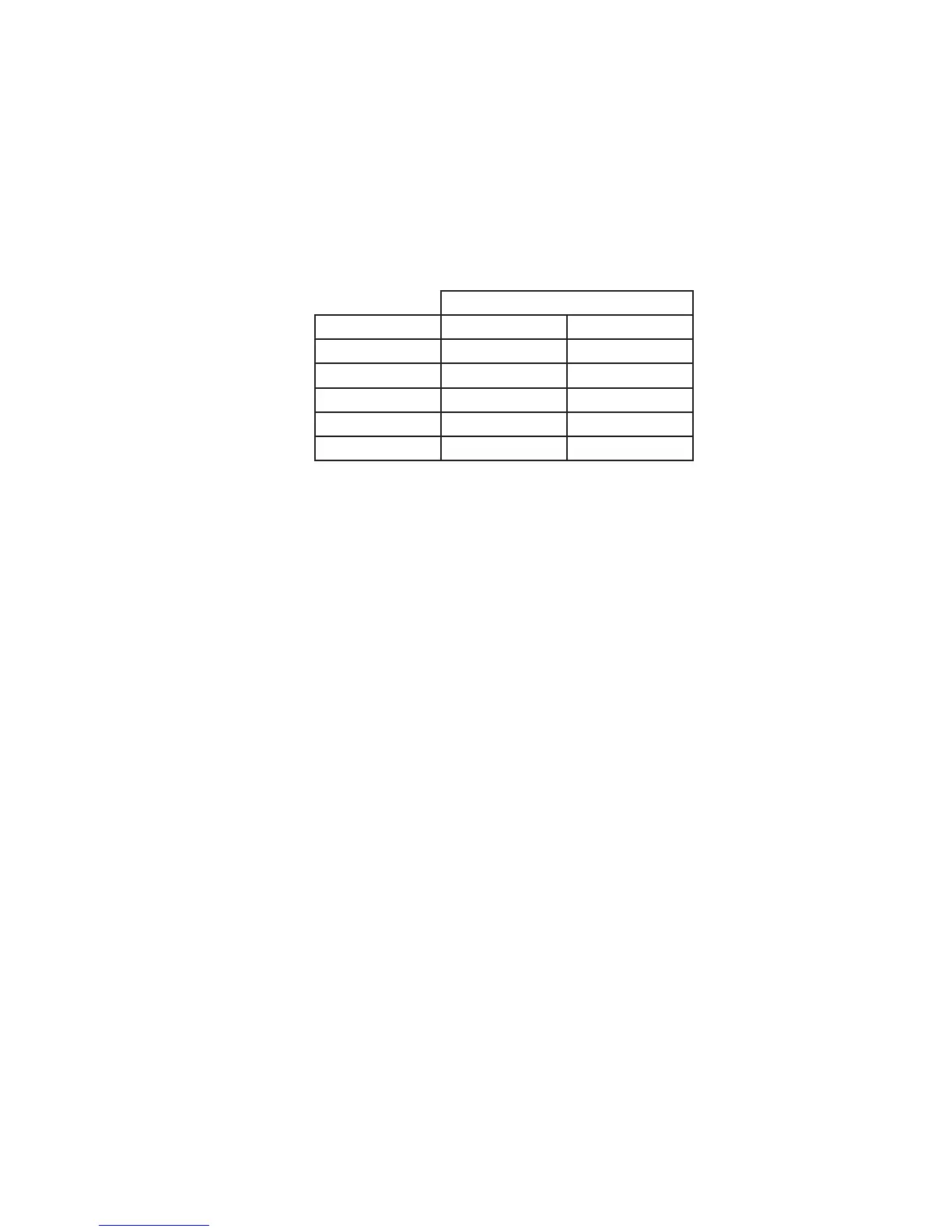

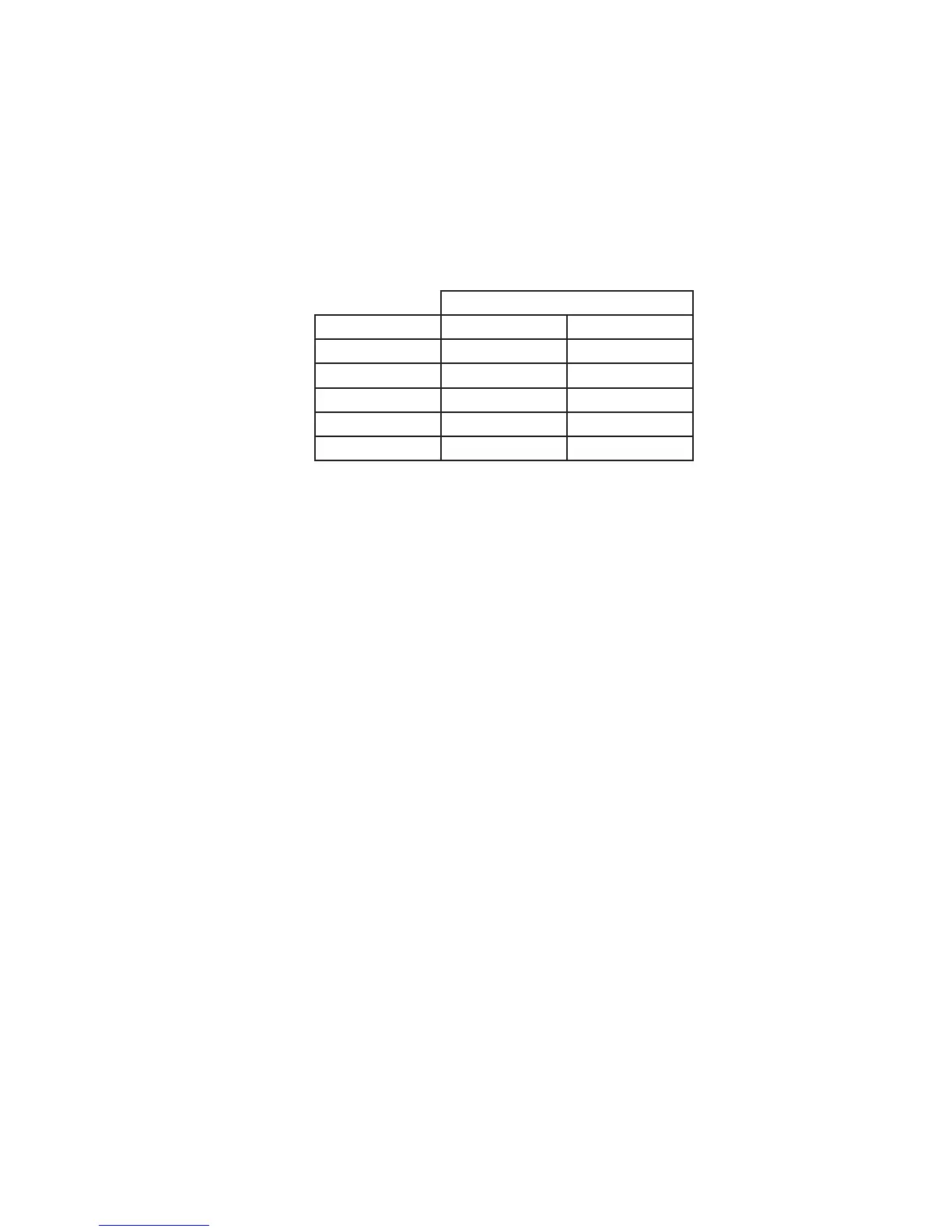

Table 9.1: Flow Limitations

Flow (GPM)

Model Minimum Maximum

80MBH 5.0 13.3

100MBH 5.1 13.3

120MBH 6.2 13.3

150MBH 7.7 13.3

180MBH 9.3 13.3

Method 1: Primary/Secondary Piping (Strongly Recommended)

This method can be used in heat-only applications as shown in Figure 9.2 or with an indirect water heater as shown

inFigure9.3AorFigure9.3B.Inthissystem,theowratethroughtheboiler(“secondaryloop”)iscompletely

independentoftheowratethroughthesystem(“primaryloop”).Usethefollowingguidelinestoensurethattheboiler

willhavetherequiredowshowninTable9.1regardlessoftheowintheheatingsystem.

1)SystemLoopPiping-Sizethesystemcirculatorandpipingtoobtainthedesignowratethroughtheheatingsystem

as you would on any other heating system. All piping between the expansion tank and secondary connection tees must

beatleast1”.Inordertokeeptheowratesinthesystemandboilerloopsindependentofeachother,provideatleast

8diametersofstraightpipeupstreamoftherstteeand4diametersdownstreamofthesecondtee.Keepthedistance

betweentheexpansiontankandtherstsecondaryteeasshortaspractical.

2)BoilerLoopPiping–AllboilersaresuppliedwithabuiltincirculatorwhichwilldelivertheowrequiredbyTable

9.1 provided both of the following conditions are met:

• Allpipingintheboilerloophasanominalsizeofatleast1”

• Theequivalentlengthofallpipingintheboilerloopis60ftorless.

To verify that the 60ft, equivalent length is not exceeded, do the following:

a) Countallttingsintheplannedboilerloop(theshadedpipinginFigure9.6).Indoingso,donotcountthe

secondaryconnectiontees,unions,orthettingssuppliedwiththeboiler(thesehavealreadybeenaccountedfor).

b) UsingTable9.4,ndtheequivalentlengthsofallttingsinthesecondaryloop.Totaltheseequivalentlengthsand

add them to the total length of planned straight pipe in the secondary loop.

c) The result is the total equivalent length of the planned boiler loop. If the equivalent length calculated in (b) is under

thelimitshowninTable9.5,theboilerpumpwillachieveaowrateandtemperatureriseapproximatelyequaltothat

shown in this table. Otherwise, the equivalent length must be reduced.

Loading...

Loading...