75

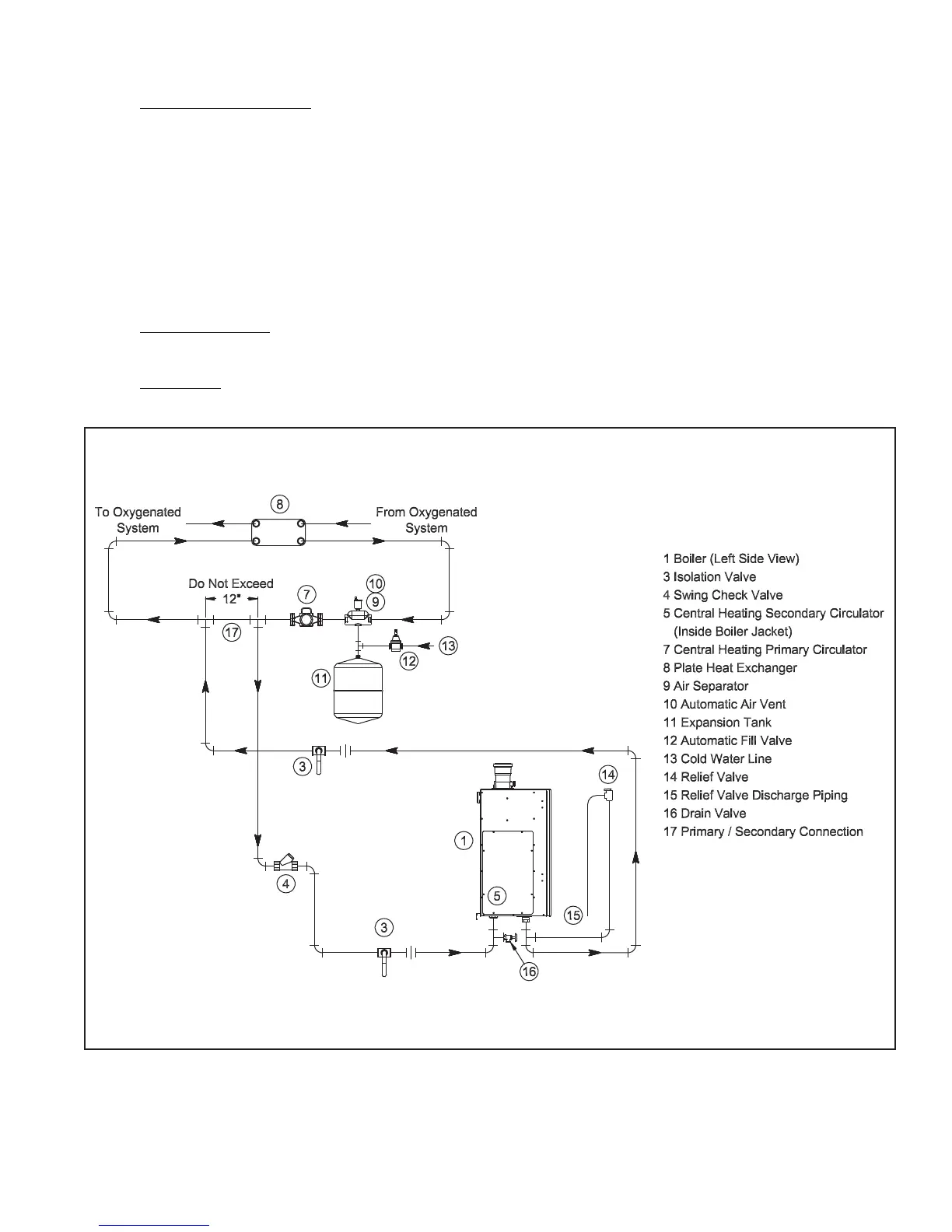

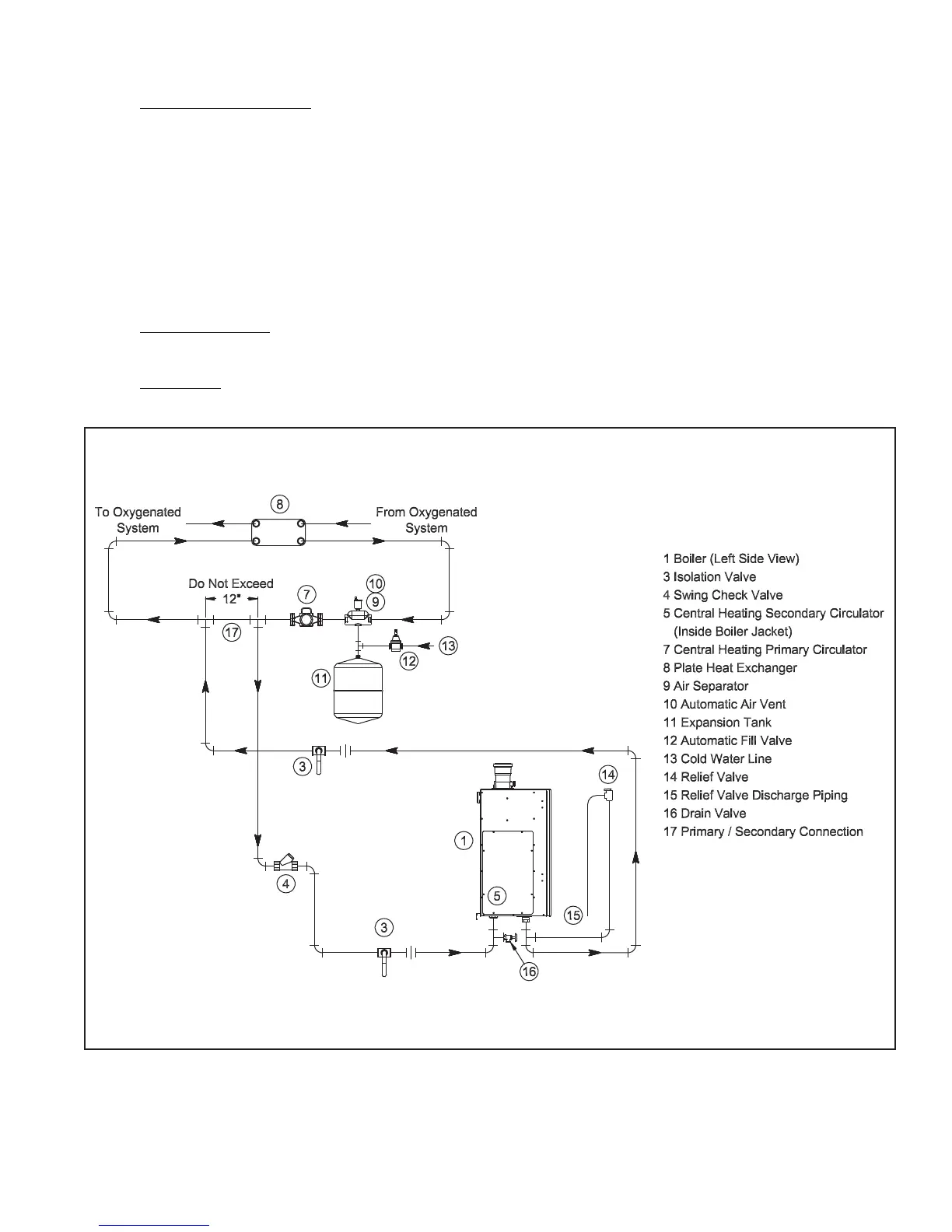

D. Piping for Special Situations

1) Systems containing oxygen - Many hydronic systems contain enough dissolved oxygen to cause severe corrosion

damage to a this boiler. Some examples include:

•Radiantsystemsthatemploytubingwithoutanoxygenbarrier.

•Systemswithroutineadditionsoffreshwater.

•Systemswhichareopentotheatmosphere.

If the boiler is to be used in such a system, it must be separated from the oxygenated water being heated with a heat

exchanger as shown in Figure 9.10. Consult the heat exchanger manufacturer for proper heat exchanger sizing as well as

owandtemperaturerequirements.Allcomponentsontheoxygenatedsideoftheheatexchanger,suchasthepumpand

expansion tank, must be designed for use in oxygenated water.

2) Piping with a Chiller - If the boiler is used in conjunction with a chiller, pipe the boiler and chiller in parallel. Use

isolation valves to prevent chilled water from entering the boiler.

3) Air Handlers-Wheretheboilerisconnectedtoairhandlersthroughwhichrefrigeratedairpasses,useowcontrol

valves in the boiler piping or other automatic means to prevent gravity circulation during the cooling cycle.

FIGURE 9.10: ISOLATION OF THE BOILER FROM OXYGENATED WATER WITH A PLATE HEAT EXCHANGER

Loading...

Loading...