PN: 2975 Rev F, 3/2004

Page 7 of 24

C R Y S T A L

engineering corporation

Measuring Vacuum

All versions of the XP2 can be used to measure moderate vacuum, though only ranges of

300 PSI (and 20 bar or 2000 kPa) and lower are actually tested and certified for vacuum

operation.

When measuring pressure less than ambient barometric conditions, a minus (-) sign will

appear. XP2s are not recommended for continuous use at high vacuum (pressures less

than -14.5 PSI, at sea level). If the pressure applied is less than -14.5 PSI or equivalent,

regardless of zero or tare, the gauge will indicate overpressure (see “Overpressure

Conditions”).

Water Density (Inches of Water)

The following applies only to models where inches of water are available. As shipped from

the factory, the XP2 is set to display inches of water corresponding to the density of water

at 4°C (39.2°F). You may require a different water density for your application, so the XP2

can be set to use the density of water at 20°C (68°F) or 15.6°C (60°F), instead. Changing

the setting can be accomplished via the keypad, or via the RS-232 interface (see: WinXP2

Configuration Software or refer to the Digital Interface section for instructions to change the

water density via RS-232).

To check and or change the water density setting from the keypad, turn on the XP2 by

pressing the (on/off) button and the

button simultaneously. The display will

indicate either “4C” or “60F” or “68F”.

Press the

button until the display cycles to the desired water density, then press the

button to store the selection (this will not zero the gauge).

Overpressure Conditions

The XP2 will read pressure up to approximately 110% of the rated pressure range. Above

110% percent of the range the display will start flashing and the readings will not be reliable.

The zero/tare function does not affect the point at which the display starts flashing to

indicate overpressure, so depending on the tare value it is possible that the display can

start flashing without the maximum pressure being displayed.

For instance, if a 100 PSI XP2 is zeroed when 30 PSI is being applied, it will indicate that

the overpressure condition has been reached at 80 PSI (i.e., 110% x 100 PSI – 30 PSI =

80 PSI).

Overpressure can affect accuracy, but the effect is only temporary unless the sensor has

been destroyed. See Specifications for maximum overpressure.

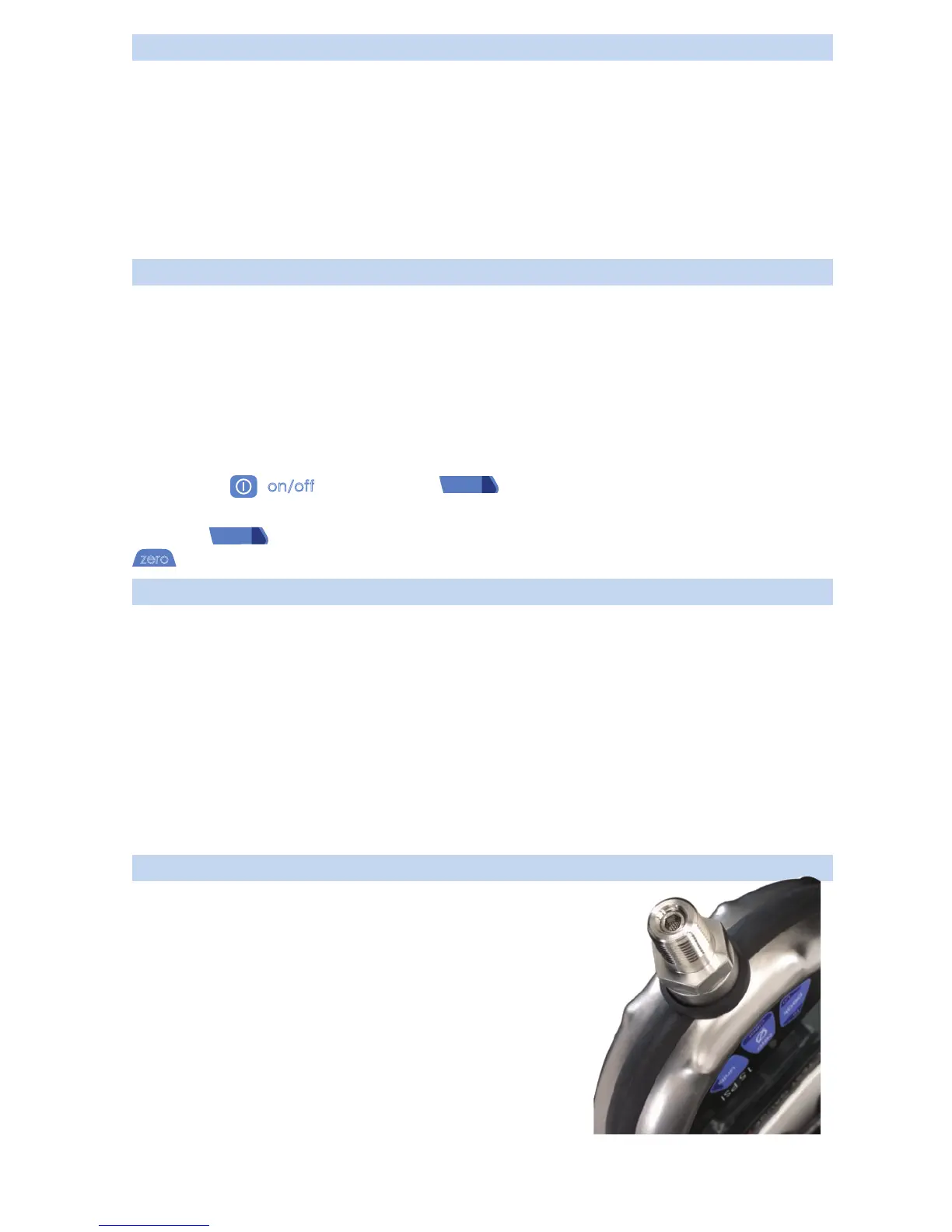

Filter

The XP2 has a removable, stainless steel mesh filter, installed in

the bottom of the pressure connection. This filter is designed to

keep large particles from becoming entrapped in the sensor cavity.

If the XP2 fails to return to zero, or returns to zero or new applied

pressures slowly, the filter may be obstructed. The filter can

be removed and cleaned if necessary, by unscrewing it with a

5

⁄

32

″ (4 mm) hex key, and using solvents and/or compressed

air to clean it out. Or, you can purchase a replacement filter,

PN:3002.

Loading...

Loading...